Method for quickly desalting dredgerfill by using desulfurization gypsum (DSG)

A technology for desulfurizing gypsum and filling soil, which is applied in the fields of land preparation methods, chemical instruments and methods, and restoration of polluted soil, etc., can solve problems such as difficulty in implementation and increase in comprehensive cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is also described in further detail in conjunction with embodiment:

[0008] 1. Leaching test

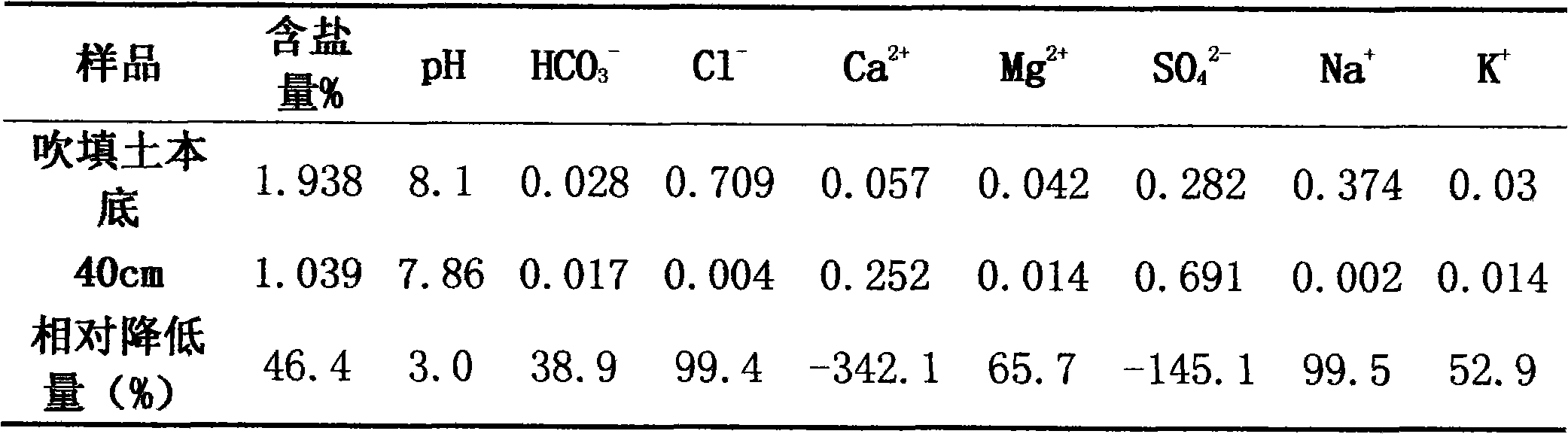

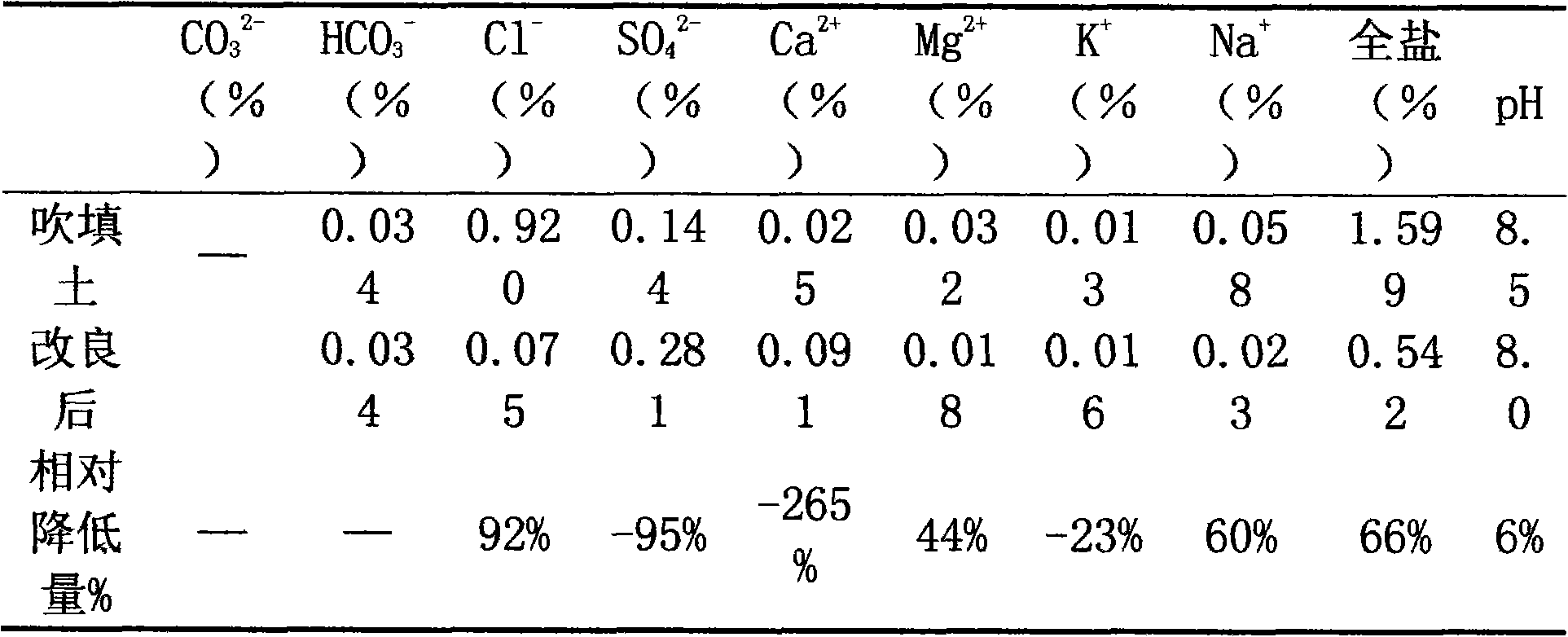

[0009] The indoor simulated leaching test was carried out with the dredged fill soil, and the changes in salinity were counted after 15 days. The results are shown in Table 1:

[0010] Table 1 Changes in salinity of 40cm dredger fill before and after improvement (%)

[0011]

[0012] Improved Cl - and Na + The content is greatly reduced, and the highest reduction rate reaches more than 99%. These two ions are the main factors that harm the growth of plants and destroy the soil structure. Their substantial reduction can provide a safe growth environment for the growth of plants.

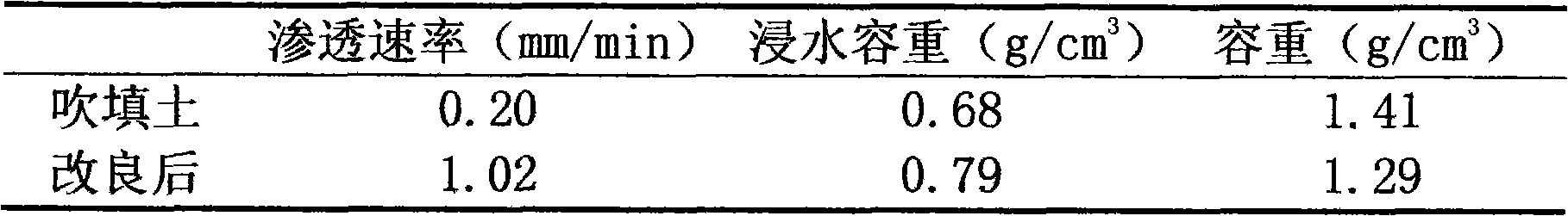

[0013] Adding desulfurization gypsum can not only significantly reduce the content of harmful ions, but also speed up the leaching time of the dredged fill. The entire column (1m) can be fully soaked in 48 hours. The thickness of the soil layer wetted by the original dre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com