Accumulator, and method for the production of an accumulator

A storage battery and lead storage battery technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve the problems of high manufacturing cost, etc., achieve low material consumption, simple modification, and improve the effect of seismic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

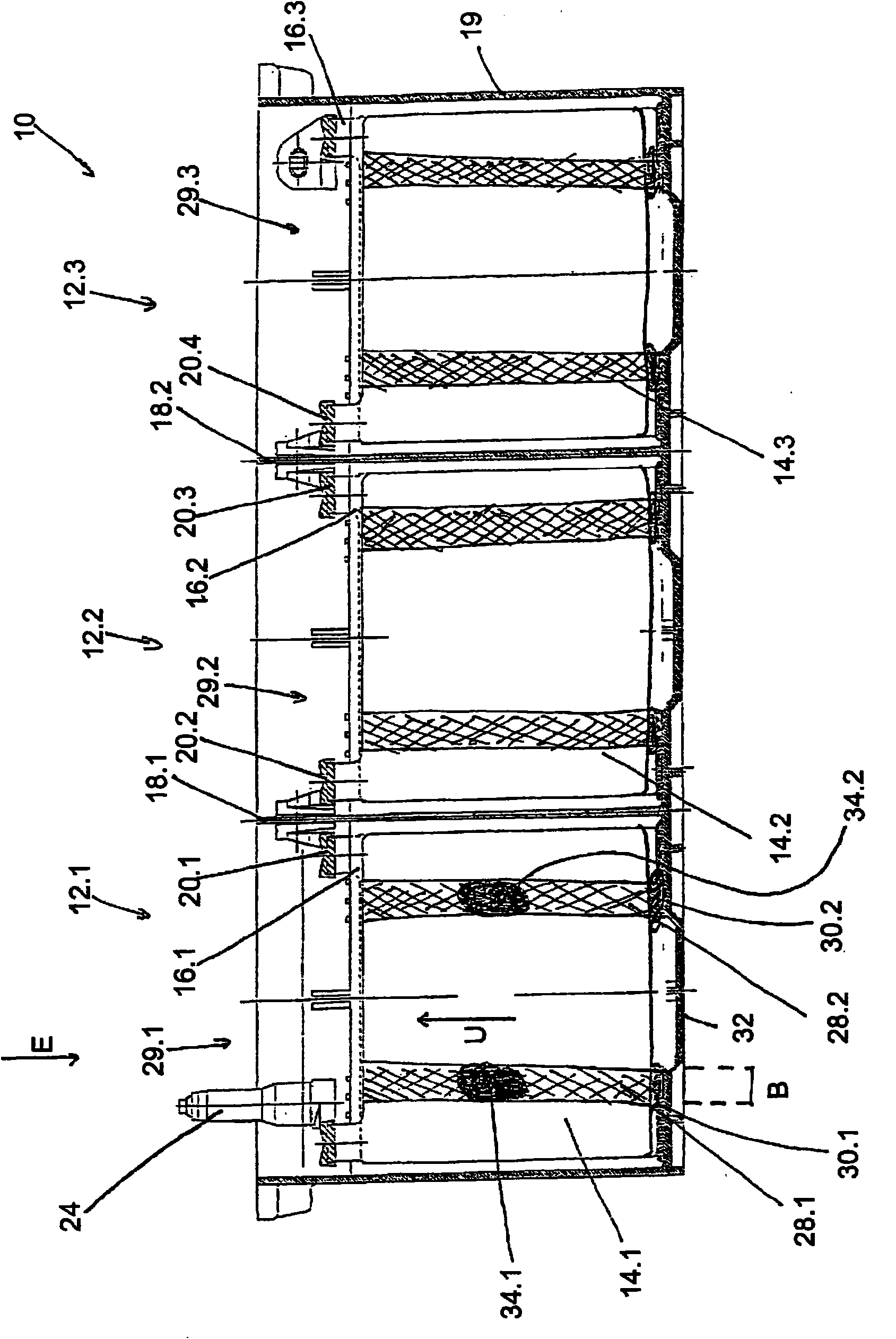

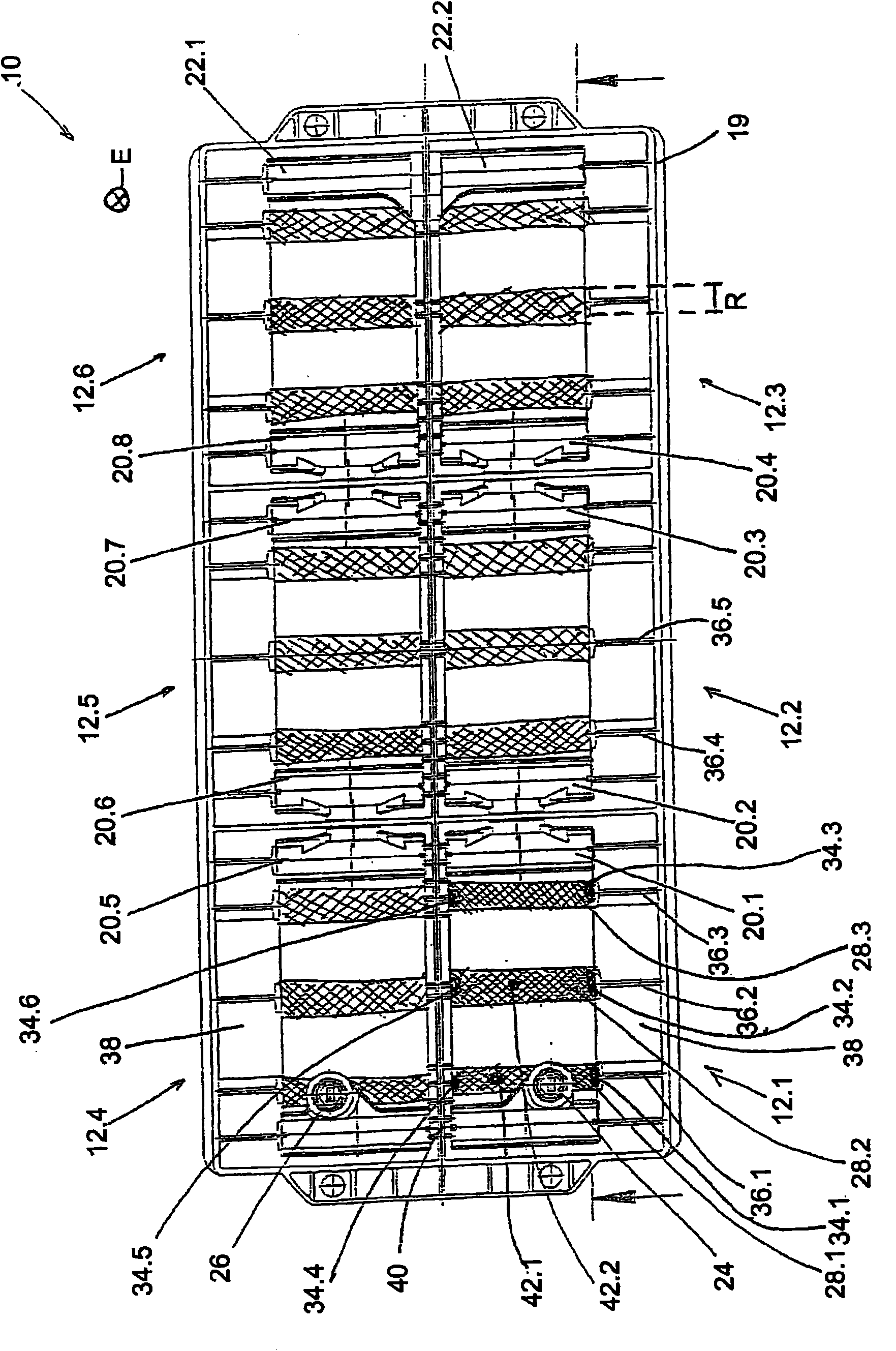

[0018] figure 1 A battery is shown in transverse section. The accumulator comprises primary cells 12.1 to 12.6, wherein, in figure 1 Galvanic cells 12.1, 12.2 and 12.3 are shown in . Galvanic cells 12.1, 12.2 and 12.3 each comprise a plurality of plates 14.1 and 14.2 and 14.3 spaced apart from one another forming a positive plate set and negative plates 16.1 and 16.2 and 16.3 forming a negative plate set. The primary cells 12.1 to 12.3 are separated spatially and electrically by separators 18.1, 18.2 and are arranged in a housing 19. In the following, reference numerals with numerical suffixes ".1", ".2", . . . denote corresponding concrete objects. Reference numerals without a numerical suffix refer to general objects.

[0019] The positive and negative plates are mechanically and electrically connected separately to connectors 20.1, 20.2, 20.3 and 20.4, respectively. The respective two connectors 20.1 and 20.2 and 20.3 and 20.4 are mechanically and electrically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com