Sterile packing and sterilization method using this packing

A sterilization method and a connecting device technology, applied in the field of aseptic packaging, can solve the problems of no packaging sterilization, etc., and achieve the effect of easy handling and operation, and increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

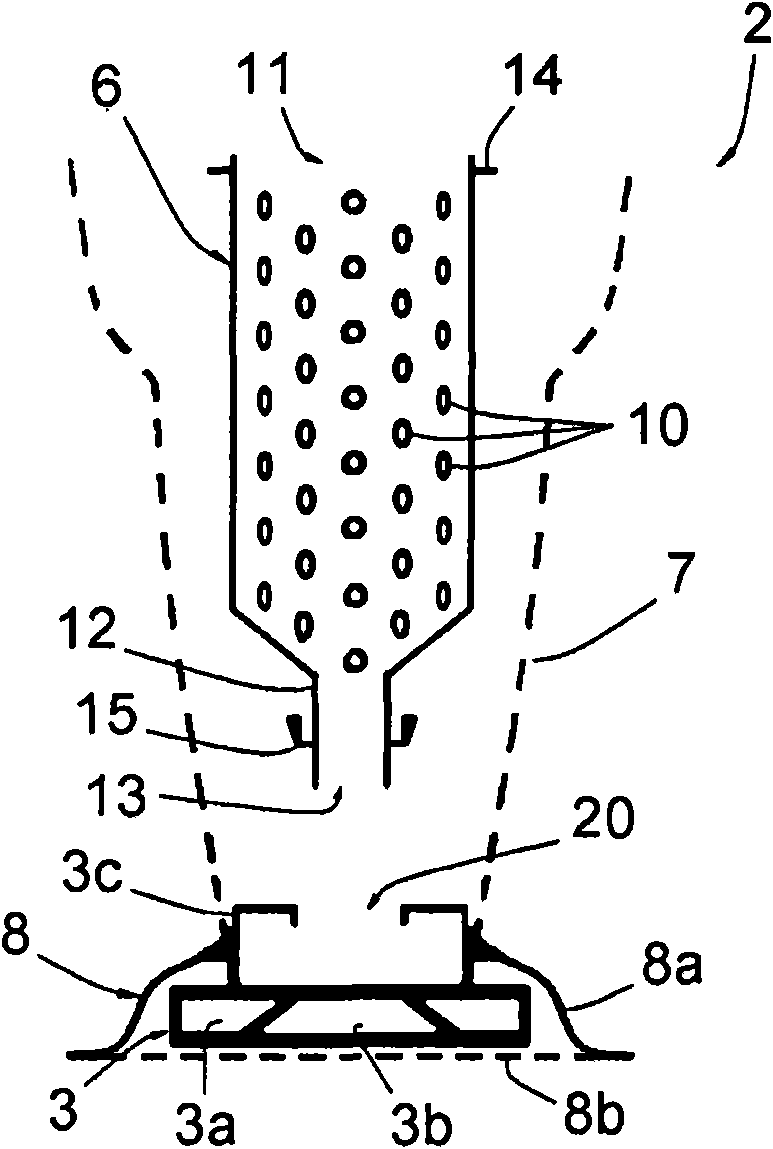

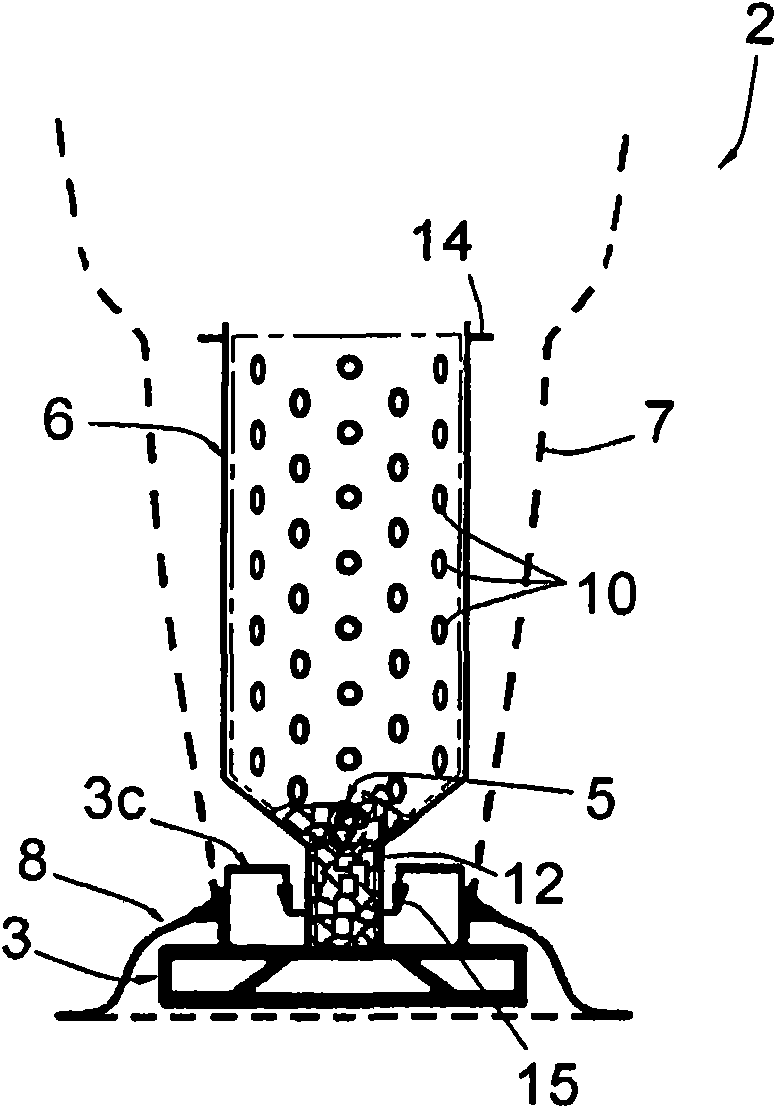

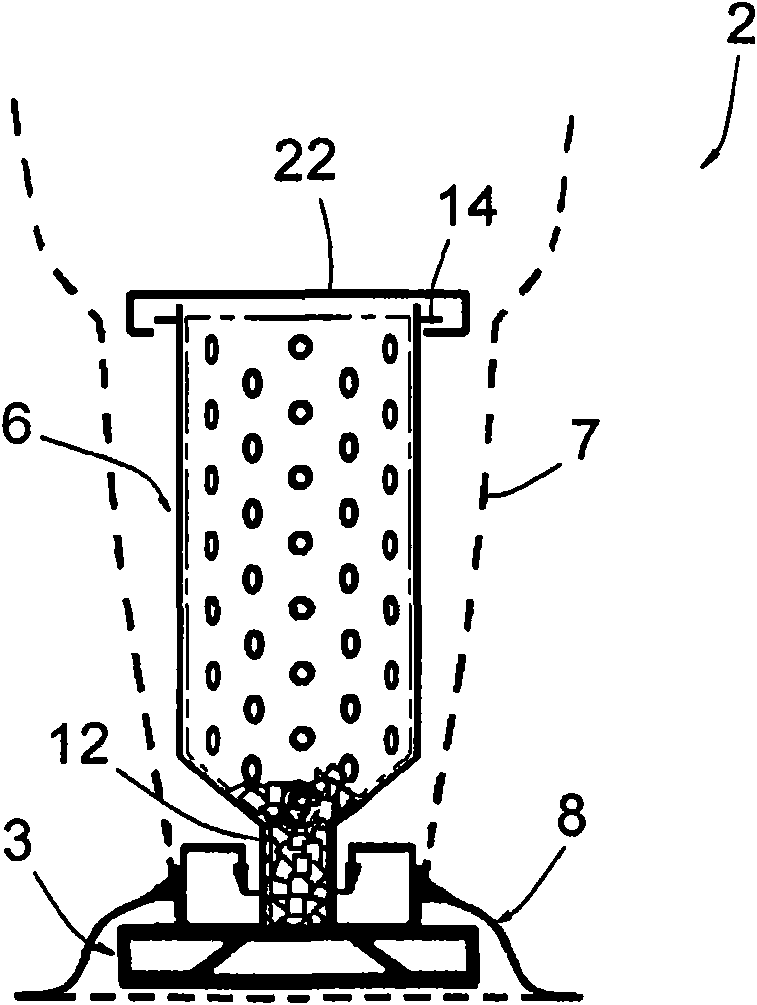

[0045] Figure 7 Shown is an aseptic package 1 formed from a container 2 comprising a connecting ring 3 and an outer envelope 4 .

[0046] The container 2 is intended to contain one or several items 5 to be sterilized, in particular constituent parts of syringes, and in particular syringe plungers. as in Figures 1 to 4 As shown more particularly in , said container 2 comprises an inner part formed by container 6 and an outer part formed by envelopes 7 and 8 .

[0047] Container 6 is rigid. This container 6 comprises a peripheral wall perforated with a plurality of small holes 10 , the size of which is smaller than that of the objects 5 . Such as figure 1 As shown, the peripheral wall defines at one end an upper opening 11 for admitting the articles 5 , and at the other end forms a duct 12 terminating in a lower opening 13 for expelling the articles 5 . The container 6 also includes a flange 14 folded back from the upper edge of the container to be able to receive the closu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com