Travel vehicle

A vehicle and driving body technology, applied to vehicle parts, non-deflectable wheel steering, agricultural machinery and implements, etc., can solve the problems of complexity, narrow operating seat space, and increased cost of parts, so as to reduce the number of parts and improve comfort The effect of improving and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

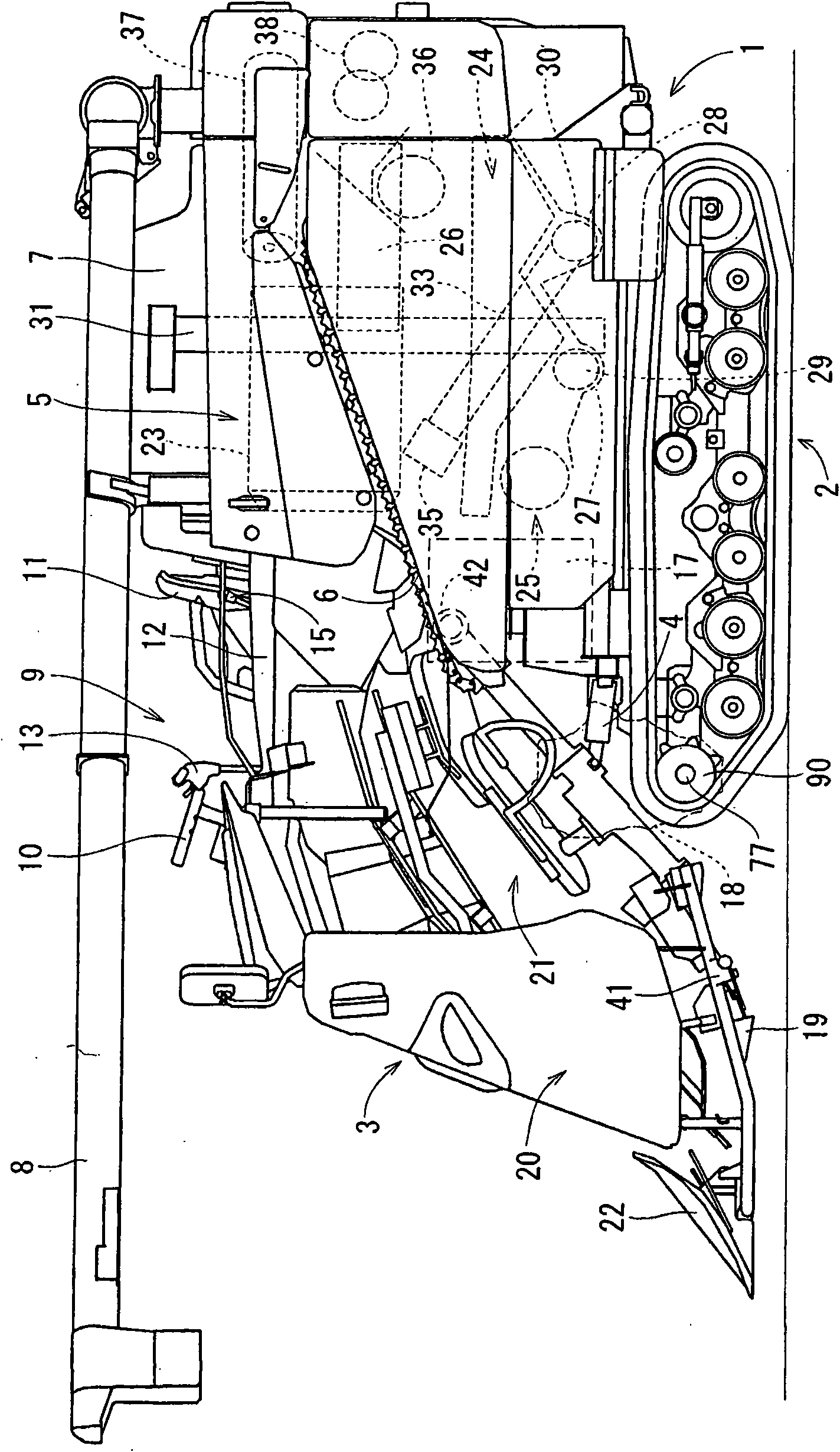

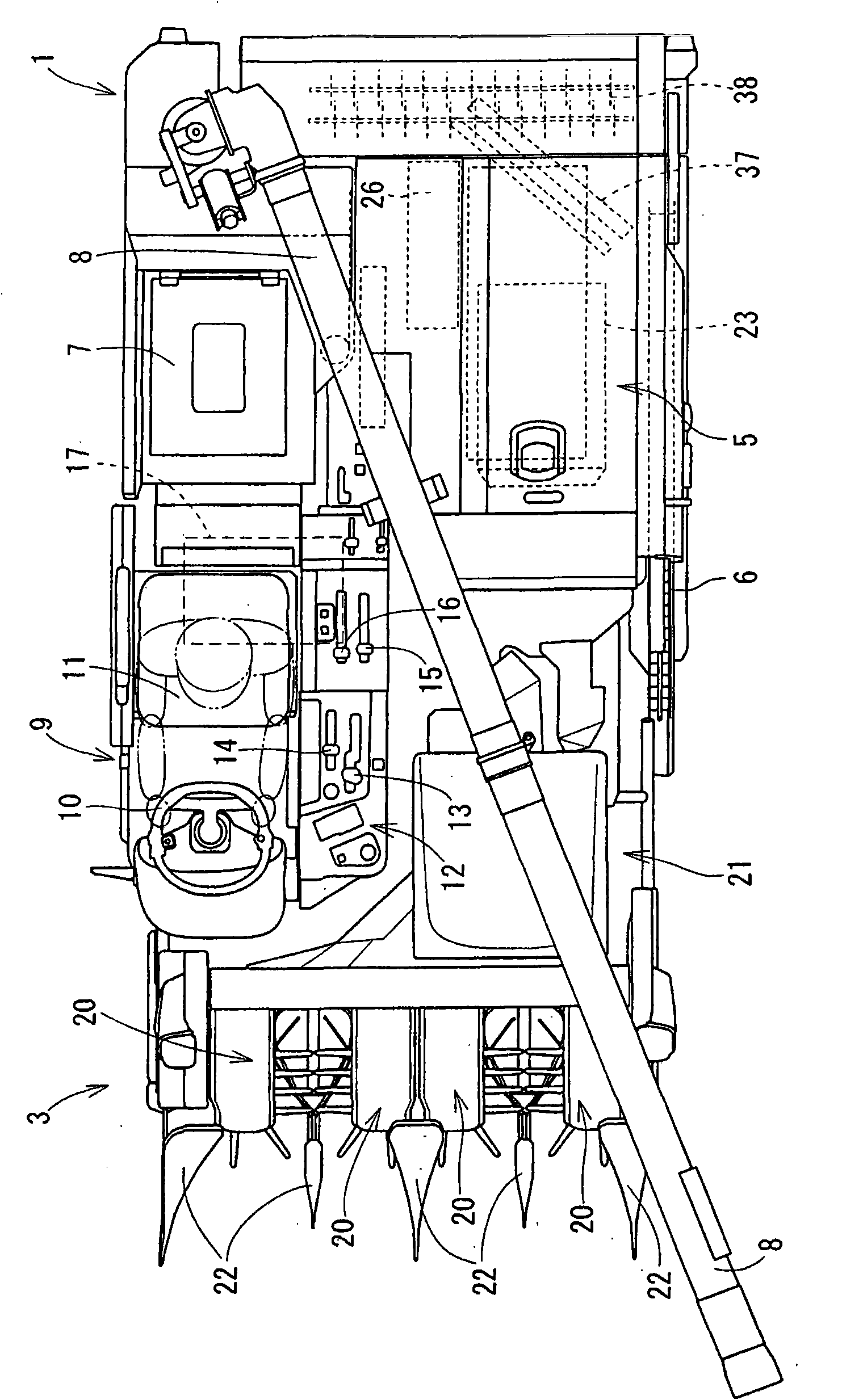

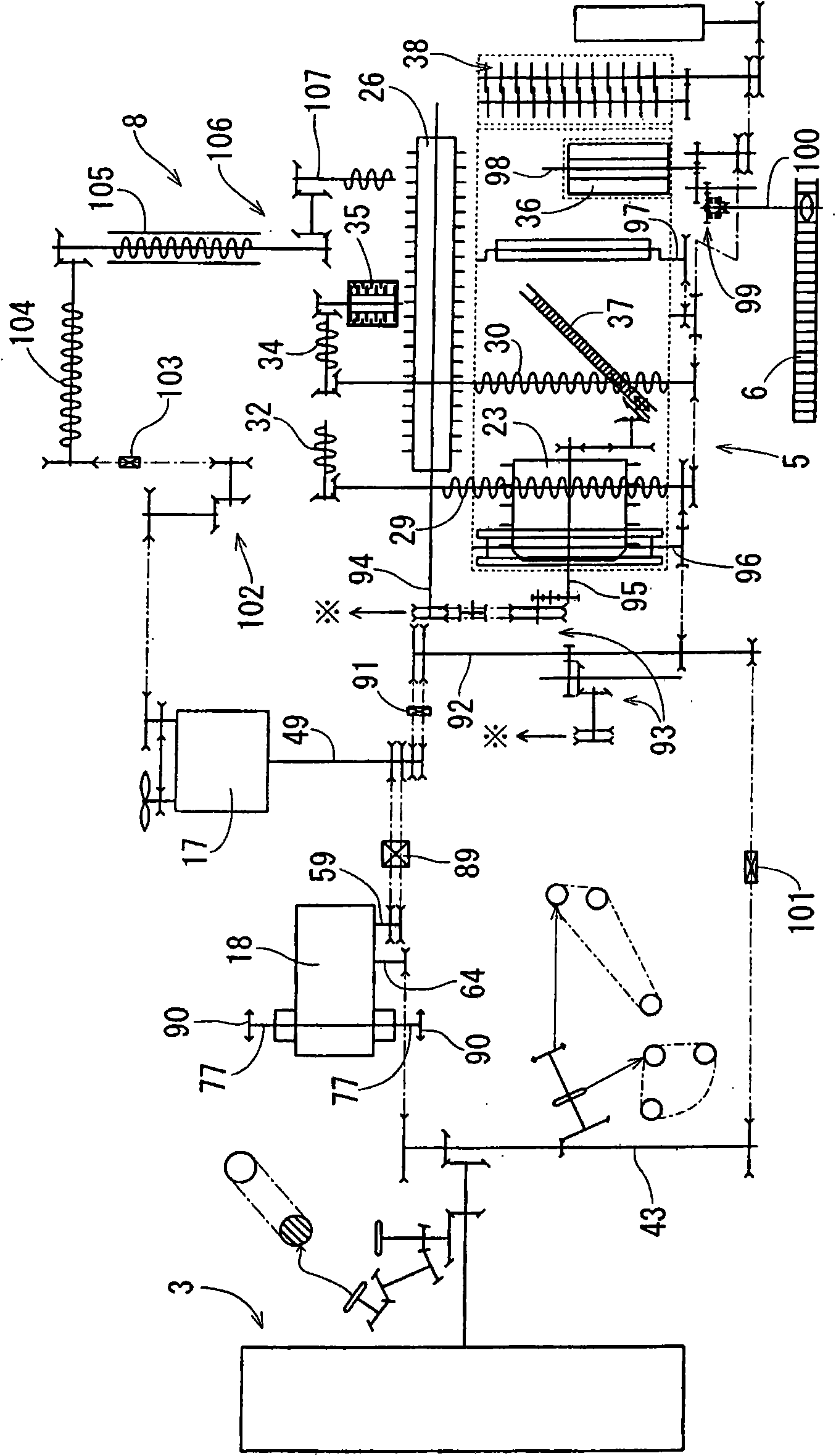

[0093] Next, the embodiment which actualized this invention is demonstrated based on drawing applied to the combine which is a traveling vehicle.

[0094] (1) The general structure of the combine harvester

[0095] First, refer to figure 1 and figure 2 The schematic structure of the combine harvester which concerns on 1st Embodiment is demonstrated.

[0096] A combine harvester which is an example of a traveling vehicle is equipped with the traveling body 1 supported by a pair of right and left traveling crawler belts 2 and 2 as a traveling part. The front portion of the traveling body 1 is equipped with a harvesting device 3 that can be adjusted up and down by a single-acting hydraulic cylinder 4 to harvest the grain stalks (uncut grain stalks) of the farm while harvesting.

[0097] The threshing apparatus 5 with the feed chain 6, and the grain box 7 which store|stores the grain after threshing are mounted side by side on the traveling body 1. As shown in FIG. In this ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com