Thermoelectric composite crude oil processor

A processor and crude oil technology, applied in the petroleum industry, hydrocarbon oil dehydration/demulsification, etc., can solve the problems of large installation and maintenance workload, single equipment function, and many equipment bodies, etc., to save land occupation, investment and maintenance. Low cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

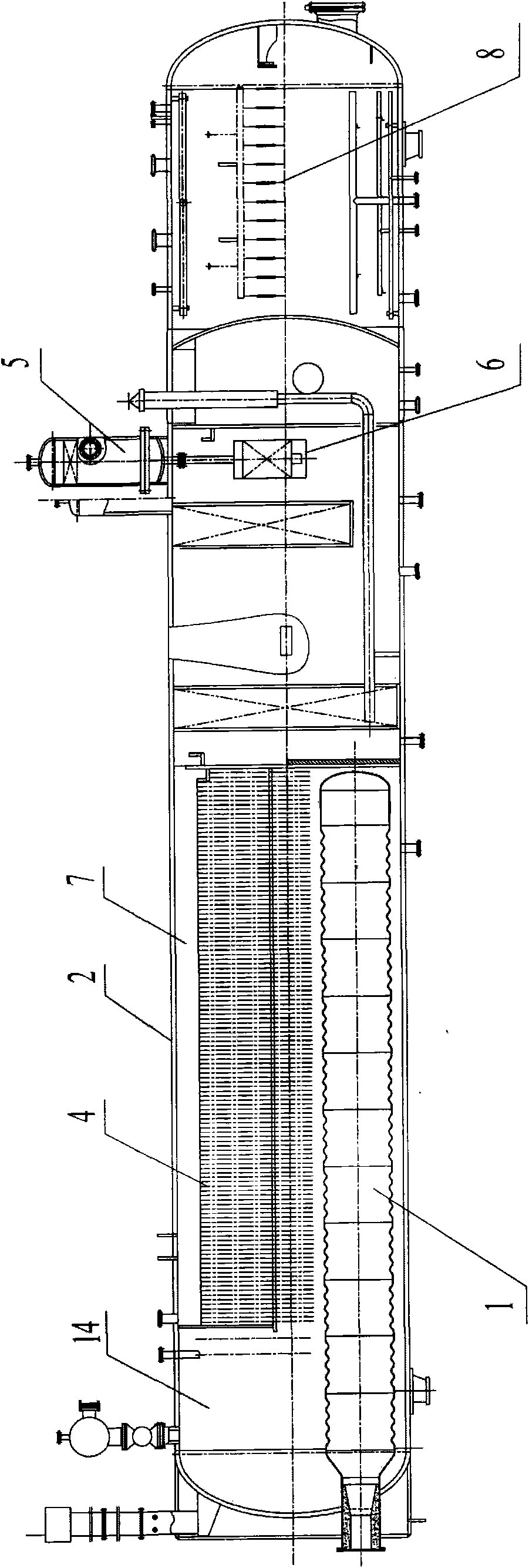

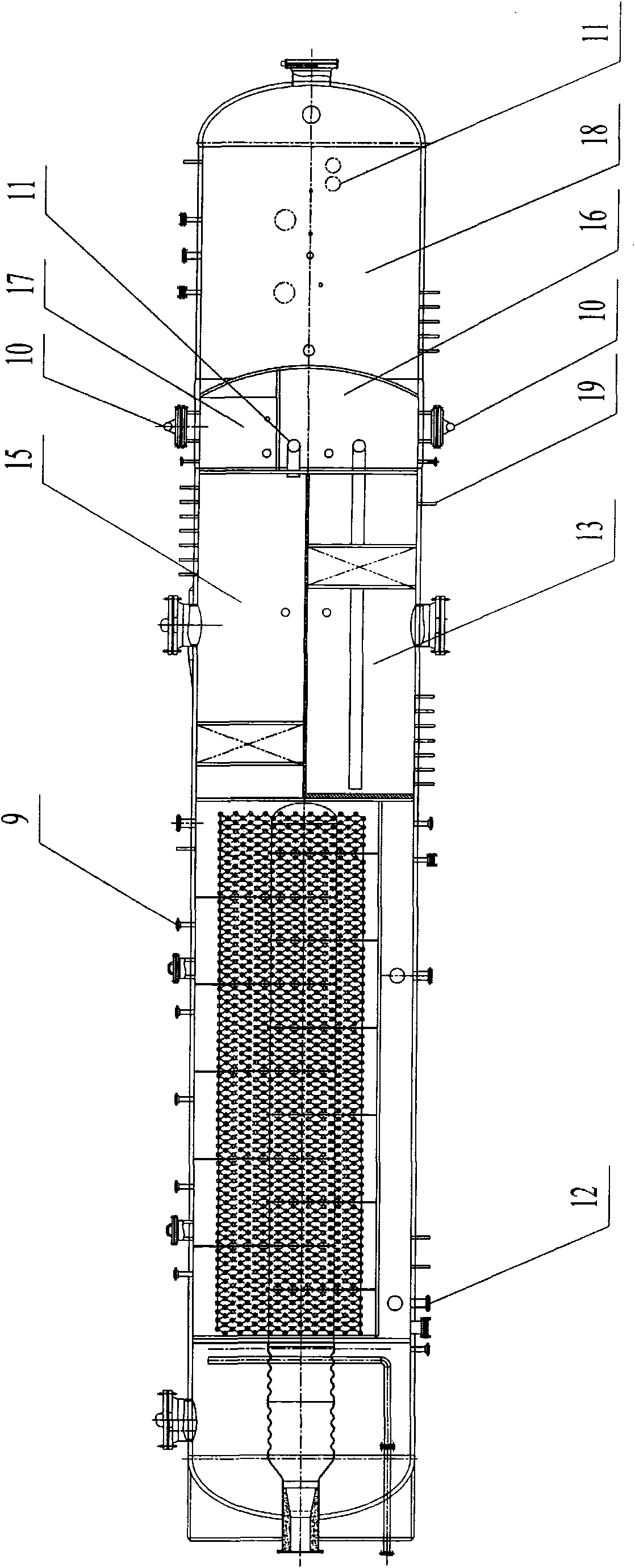

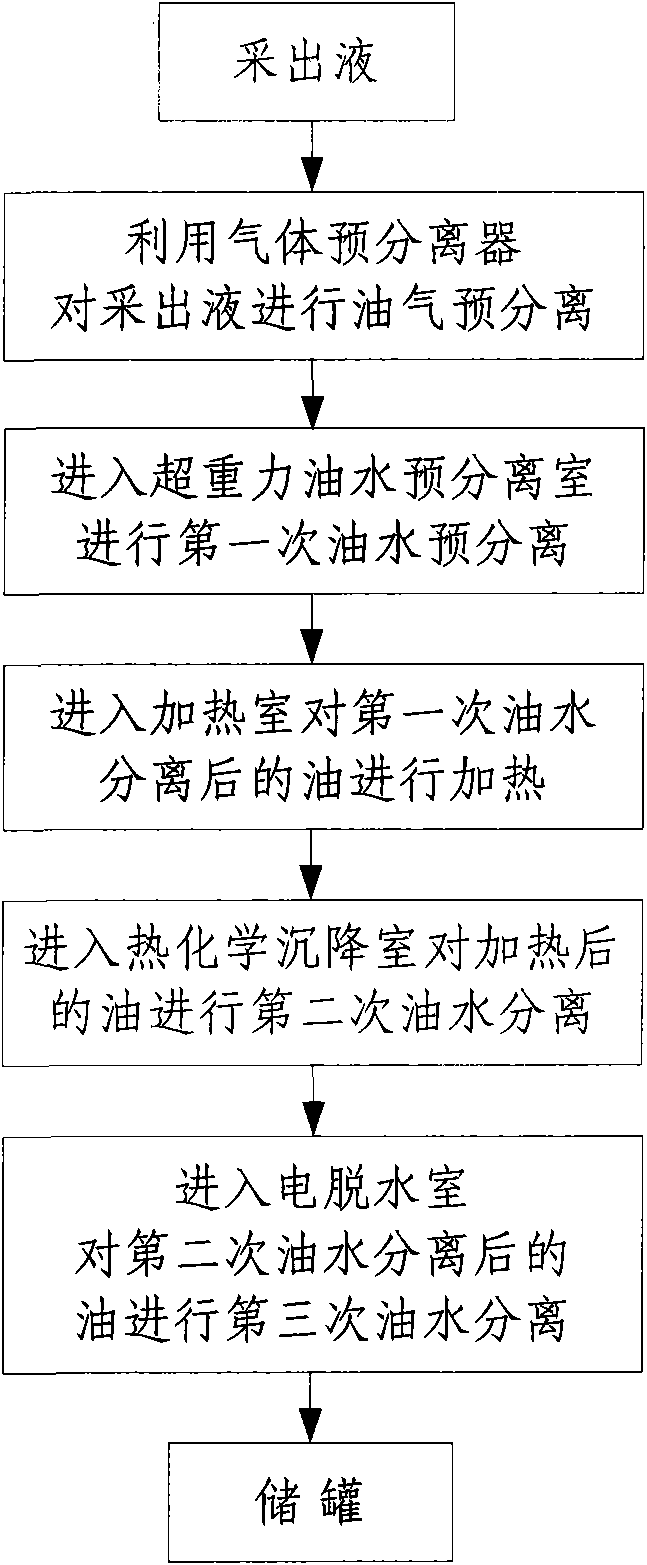

[0032] figure 1 It is a schematic diagram of the facade of the thermoelectric composite crude oil processor of the present invention, figure 2 It is a schematic top view of the thermoelectric composite crude oil processor of the present invention. Such as figure 1 , figure 2 As shown, the thermoelectric composite crude oil processor of the present invention includes a housing 2 and a gas pre-separator 5, the gas pre-separator 5 is arranged on the top of the housing, and the gas pre-separator 5 is used to separate the gas in the production liquid. The casing includes an oil-water pre-separation chamber 13 , a heating furnace chamber 14 , a heating chamber 7 , a thermochemical sedimentation chamber 15 , a water chamber 16 , an oil chamber 17 , and an electric dehydration chamber 18 . The oil-water pre-separation chamber 13 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com