Injector assembly, chemical reactor and chemical process

A technology of reactors and injectors, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve problems such as reactor wall corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] This prophetic example is provided to further illustrate the invention.

[0086] Carrying out the method of the present invention for the production of titanium dioxide as described above and Figure 10 and 11 described in. The chemical reactor 18 of the present invention is used in the process. A preheated oxygen feed 120 and a preheated titanium tetrachloride gas feed 122 are introduced into the first reaction zone 136 of the reactor conduit 16 of the reactor 18 in such a manner that the materials flow along their longitudinal axis 20 as a combined reaction feed 12 Through the reactor pipe 16. The flow rate of mixed reaction mass 12 through reactor conduit 16 was 2.5 kg / sec. The temperature of the mixed reaction mass 12 is 1300 degrees Kelvin. The reactor pipe 16 has a diameter of 125 cm (7 inches).

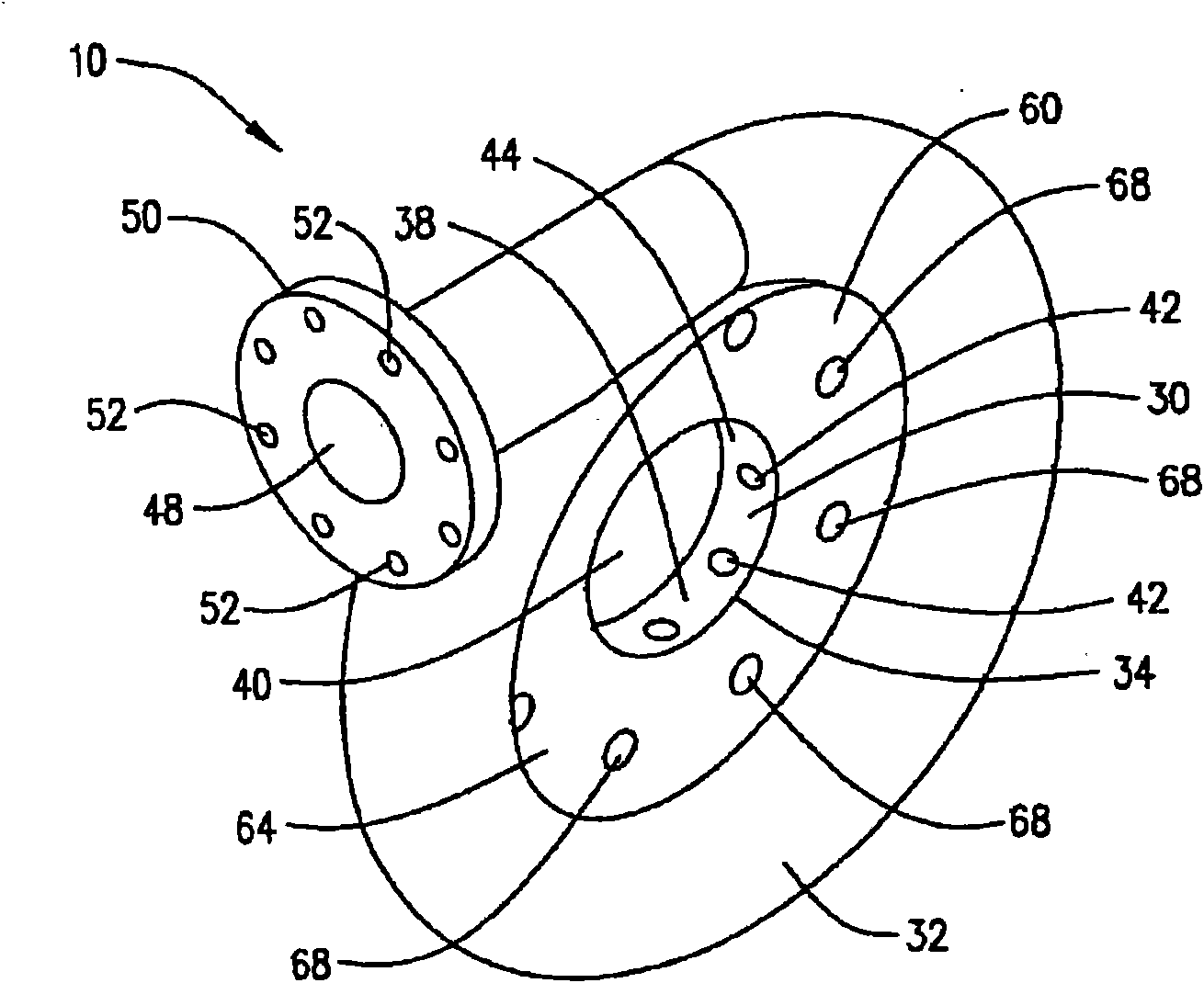

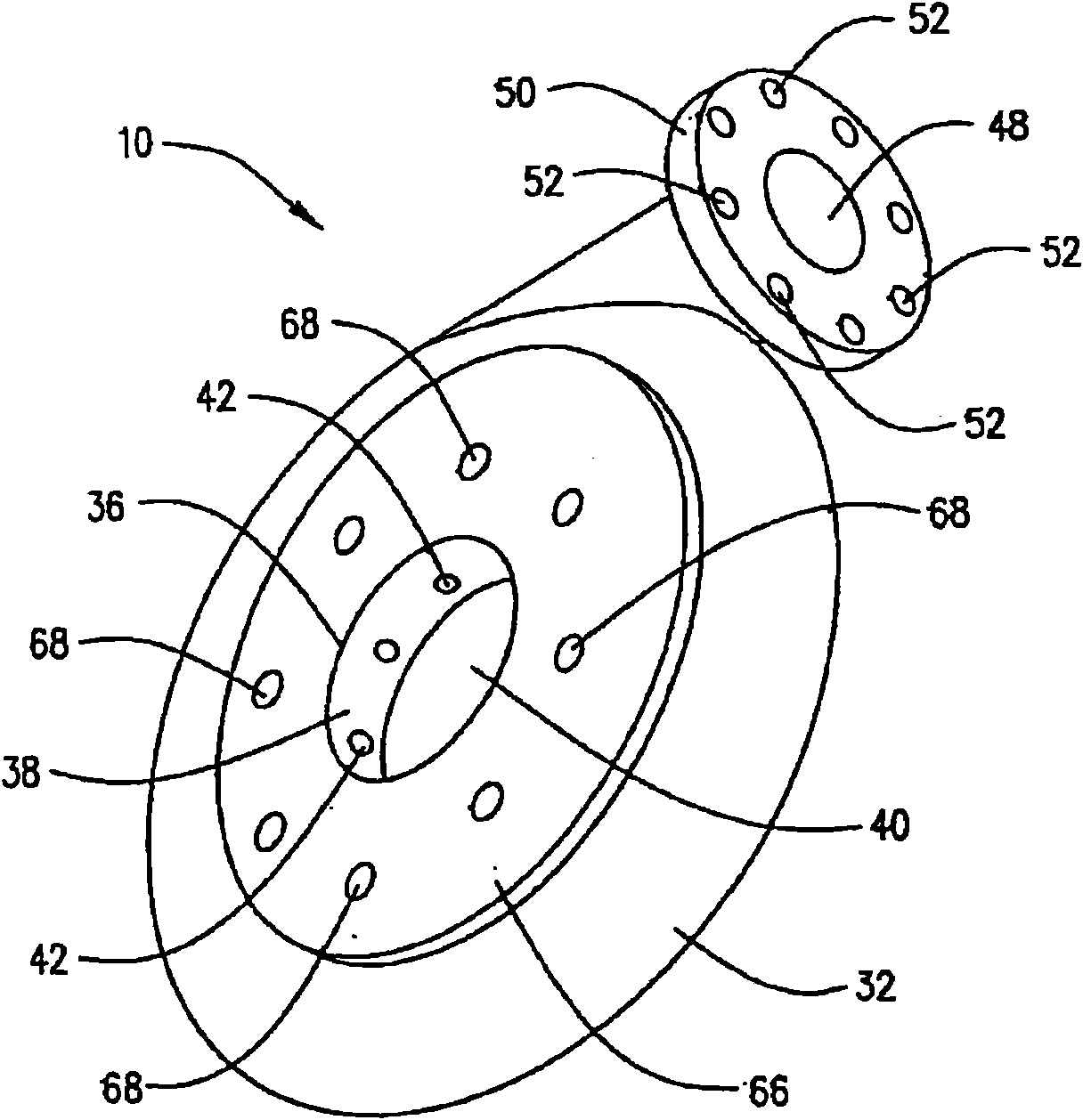

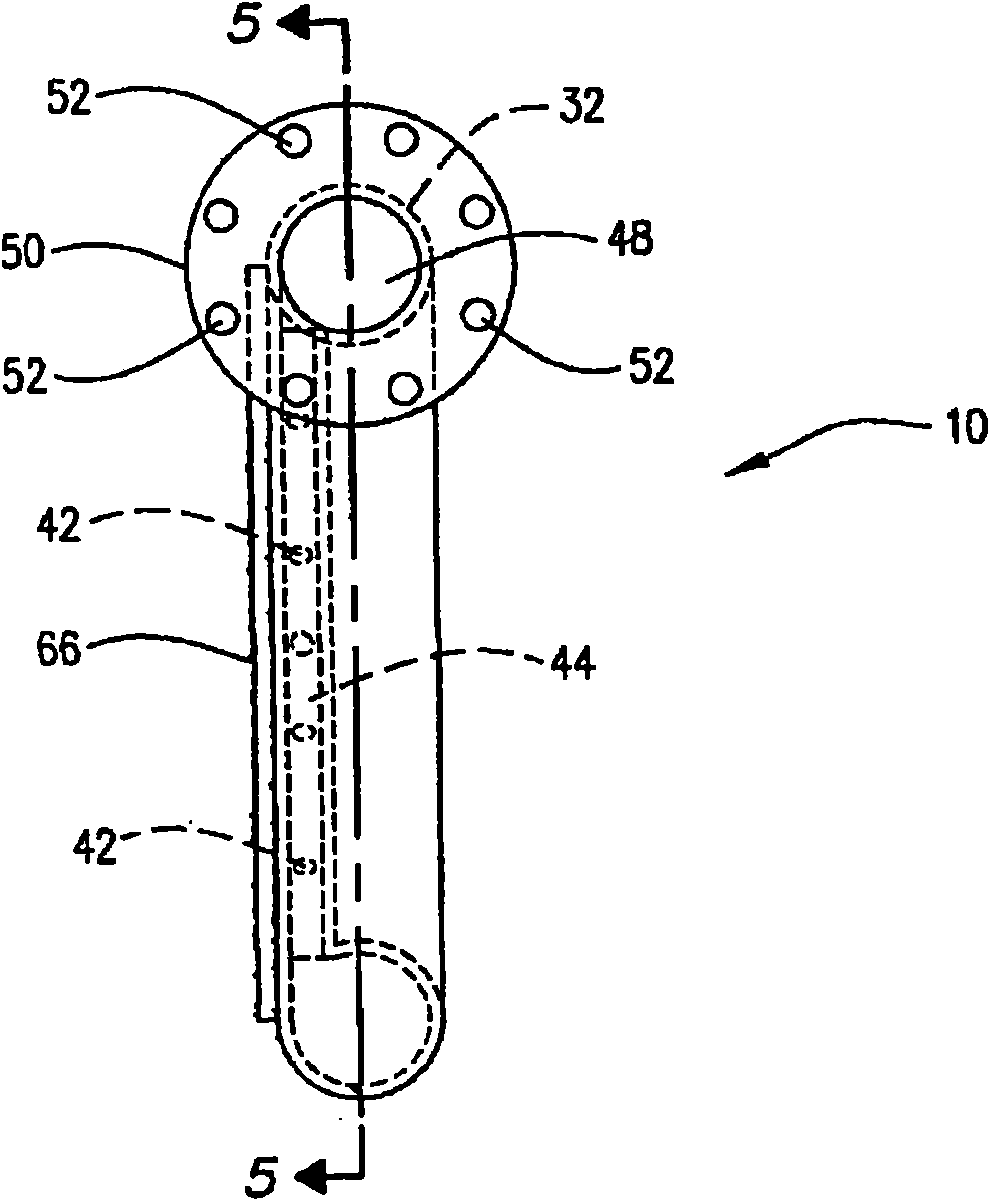

[0087] Auxiliary oxygen is then added to the second reaction zone 220 via the injector assembly 10 . Syringe assembly 10 includes eight ports 42 equally spaced ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com