Structure for high-voltage on-line temperature monitoring of photo-electric conversion embedded pole

A technology of solid-sealing poles and photoelectric converters, applied in radiation pyrometry, electrical radiation detectors, measuring devices, etc., can solve problems such as poor heat dissipation and insulation aging of contact boxes, to prevent switchgear accidents, reduce The effect of reducing power failure loss and improving the reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

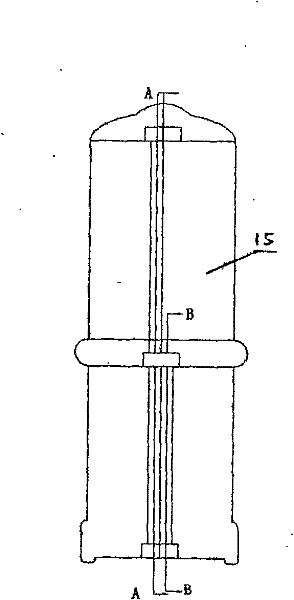

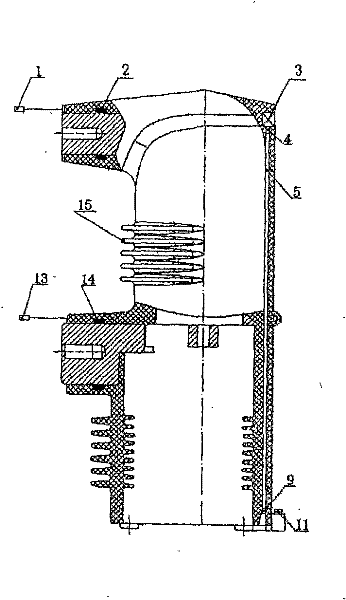

[0014] see figure 1 , figure 2 and image 3 , there is a solid-sealed pole main body 15, and the solid-sealed pole main body 15 is provided with an upper contact temperature sensing unit and a lower contact temperature sensing unit; An upper induction power supply 2 is embedded in the upper outlet seat of the upper outlet, and an upper photoelectric converter 3 is provided at the upper end of the solid-sealed pole main body 15. The upper induction power supply 2 is connected to the upper photoelectric converter 3 through embedded wires, and the upper photoelectric converter 3 is connected to There is an upper heat detector 1, the upper heat detector 1 and the upper movable contact of the external handcart touch the sensing temperature signal, the inner end of the upper photoelectric converter 3 is connected with the upper infrared emission tube 4, and the upper infrared emission tube 4 corresponds to the upper gas Gap channel 5, the other end of upper air gap channel 5 is p...

Embodiment 2

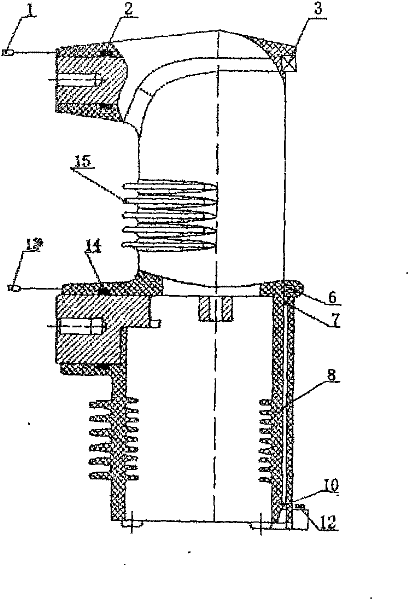

[0016] see figure 1 , Figure 4 and Figure 5 , there is a solid-sealed pole main body 15, and the solid-sealed pole main body 15 is provided with an upper contact temperature sensing unit and a lower contact temperature sensing unit; An upper induction power supply 2 is embedded in the upper outlet seat of the upper outlet, and an upper photoelectric converter 3 is provided at the upper end of the solid-sealed pole main body 15. The upper induction power supply 2 is connected to the upper photoelectric converter 3 through embedded wires, and the upper photoelectric converter 3 is connected to There is an upper heat detector 1, the upper heat detector 1 and the upper movable contact of the external handcart touch the sensing temperature signal, the inner end of the upper photoelectric converter 3 is connected with the upper infrared emission tube 4, and the upper infrared emission tube 4 corresponds to the upper gas Gap channel 5, the upper infrared emission tube 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com