Dual-rotor mechanical flow sensor and operating method thereof

A flow sensor and dual-rotor technology, applied in the direction of volume/mass flow generated by mechanical effects, by detecting the dynamic effects of fluid flow, etc., can solve ultrasonic flowmeter transmission and reception failures, mechanical flowmeter failure, ultrasonic flowmeter Ineffectiveness and other problems, to achieve the effect of eliminating random mutation measurement accuracy errors, eliminating adverse effects, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

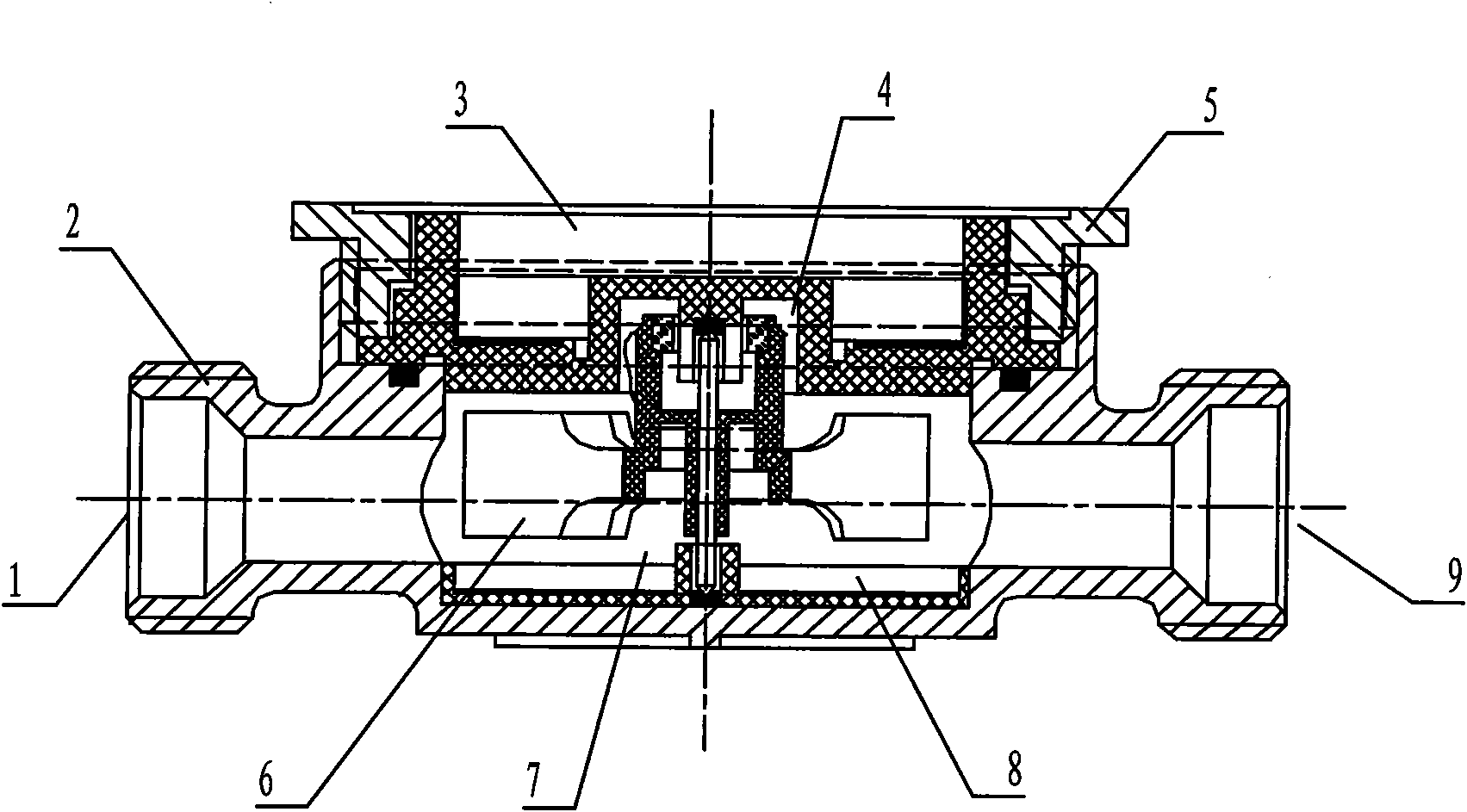

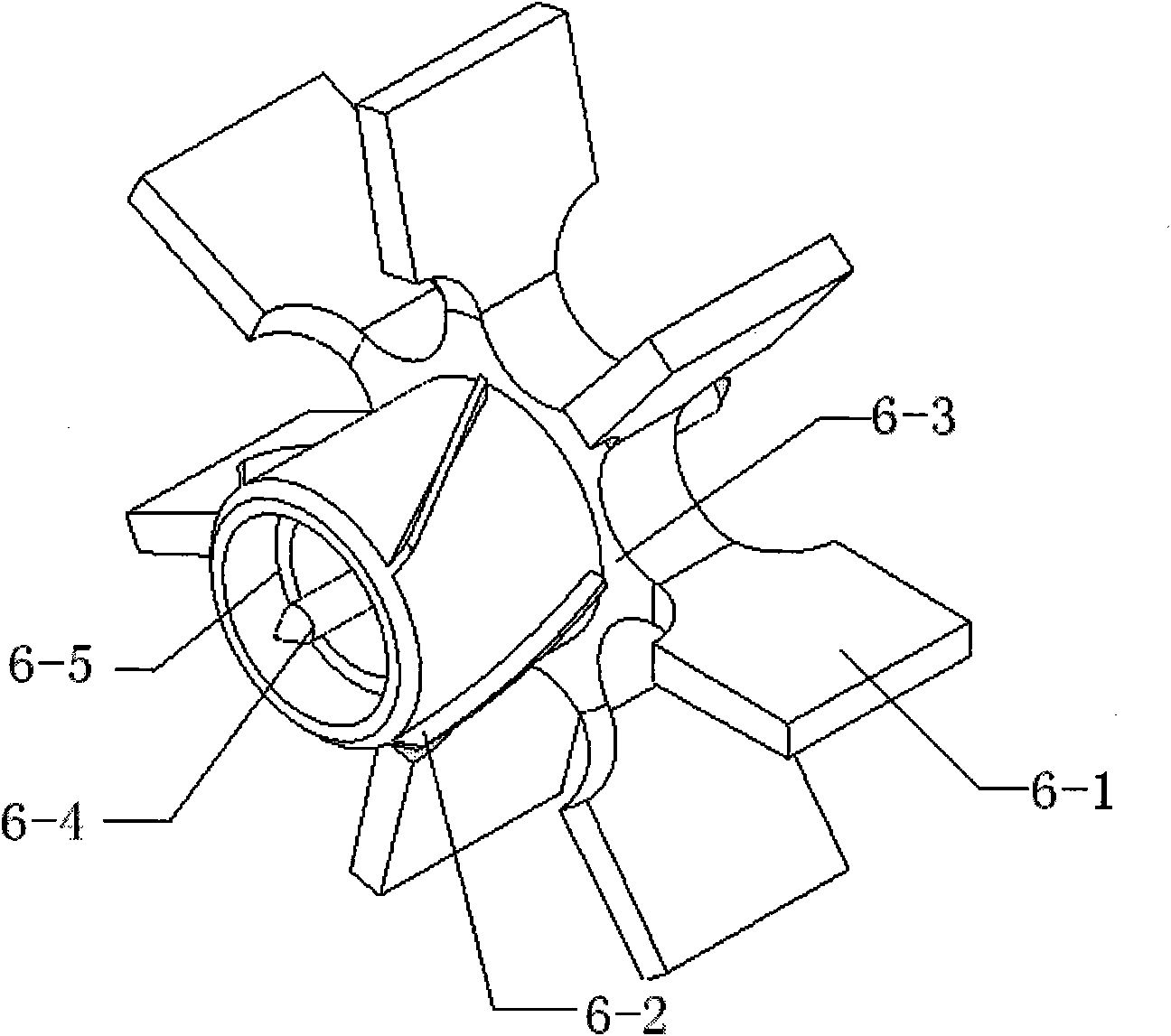

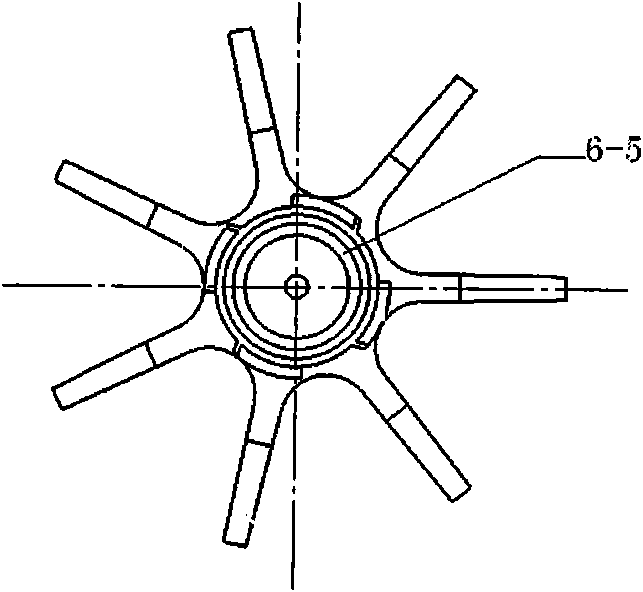

[0027] Embodiment: a kind of double-rotor mechanical flow sensor (see Figure 1-4 ), including flowmeter water inlet 1, flowmeter housing 2, flowmeter upper cover 3, metering chamber top cavity 4, flowmeter gland 5, impeller, metering chamber 7, lower support plate 8 and water outlet 9; Said lower support plate 8 is fixed on the bottom of the flowmeter housing 2; said lower end of the impeller shaft is installed in the sleeve of the lower support plate 8; said flowmeter upper cover 3 is installed in the metering chamber 7 of the flowmeter housing 2 The upper part; the upper end of the impeller shaft is installed in the sleeve of the flowmeter upper cover 3; the flowmeter gland 5 is threaded in the threaded hole on the top of the flowmeter housing 2; it is characterized in that the impeller It is a double-rotor impeller 6, which is composed of main rotor 6-1, auxiliary rotor 6-2, impeller body 6-3, impeller shaft 6-4 and sensing element 6-5; said impeller body 6-3 has Main rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com