Automatic cleaning device of indirect air cooler for power station

An air cooler and automatic cleaning technology, applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve problems such as affecting heat exchange efficiency, no vertical cleaning, and increasing operating costs, and achieves simple and reasonable structure. Good effect and high comprehensive efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

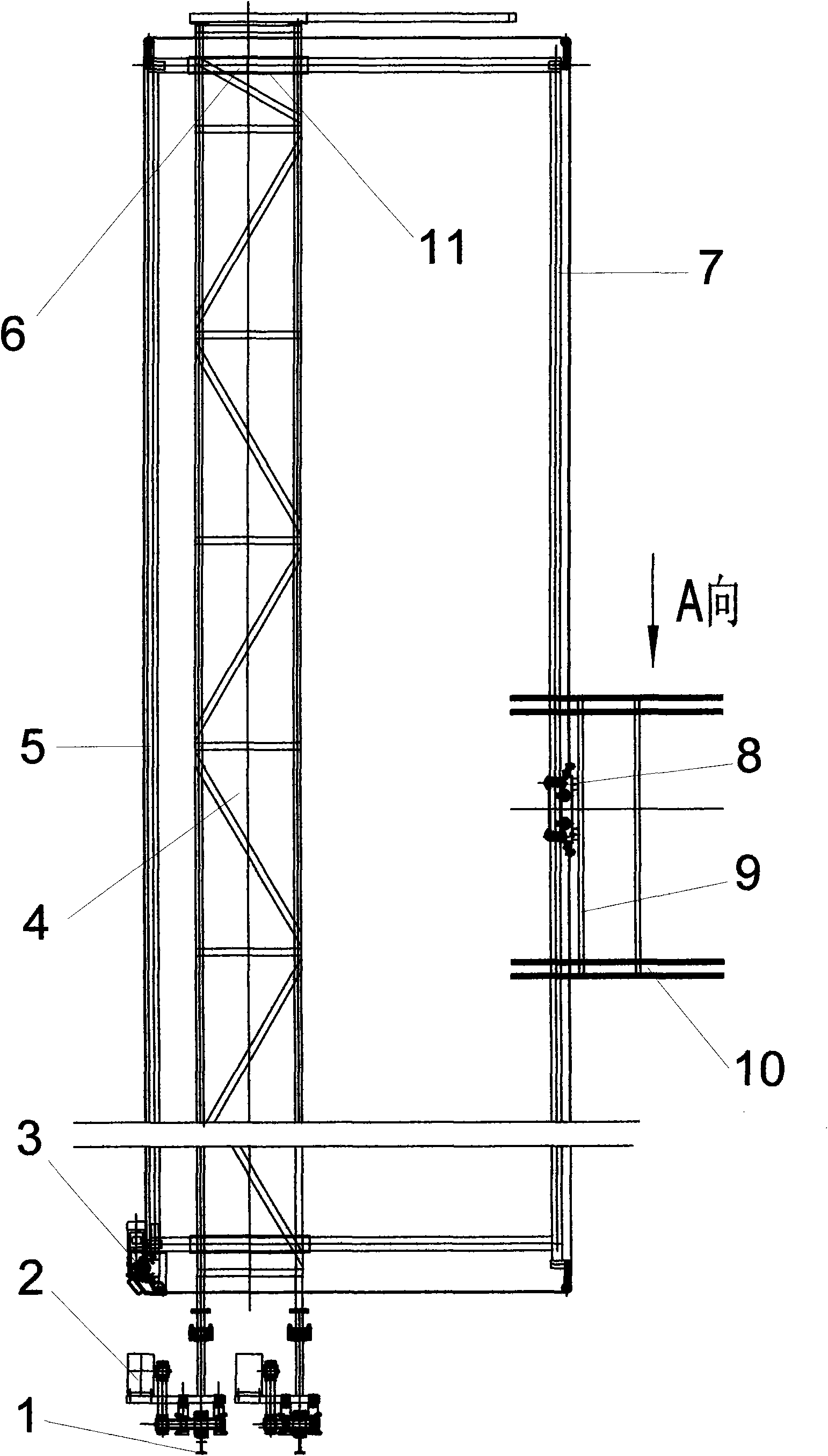

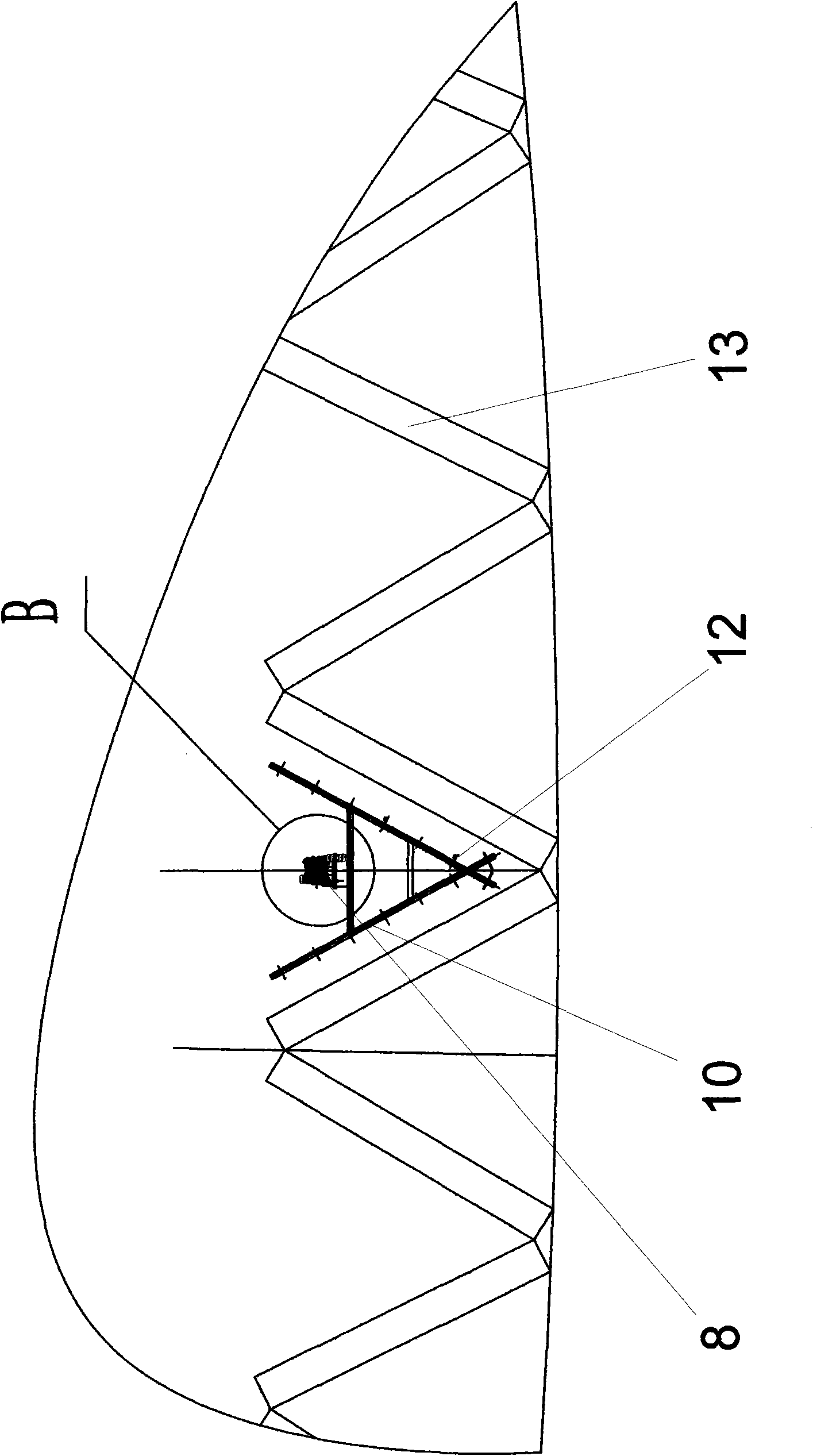

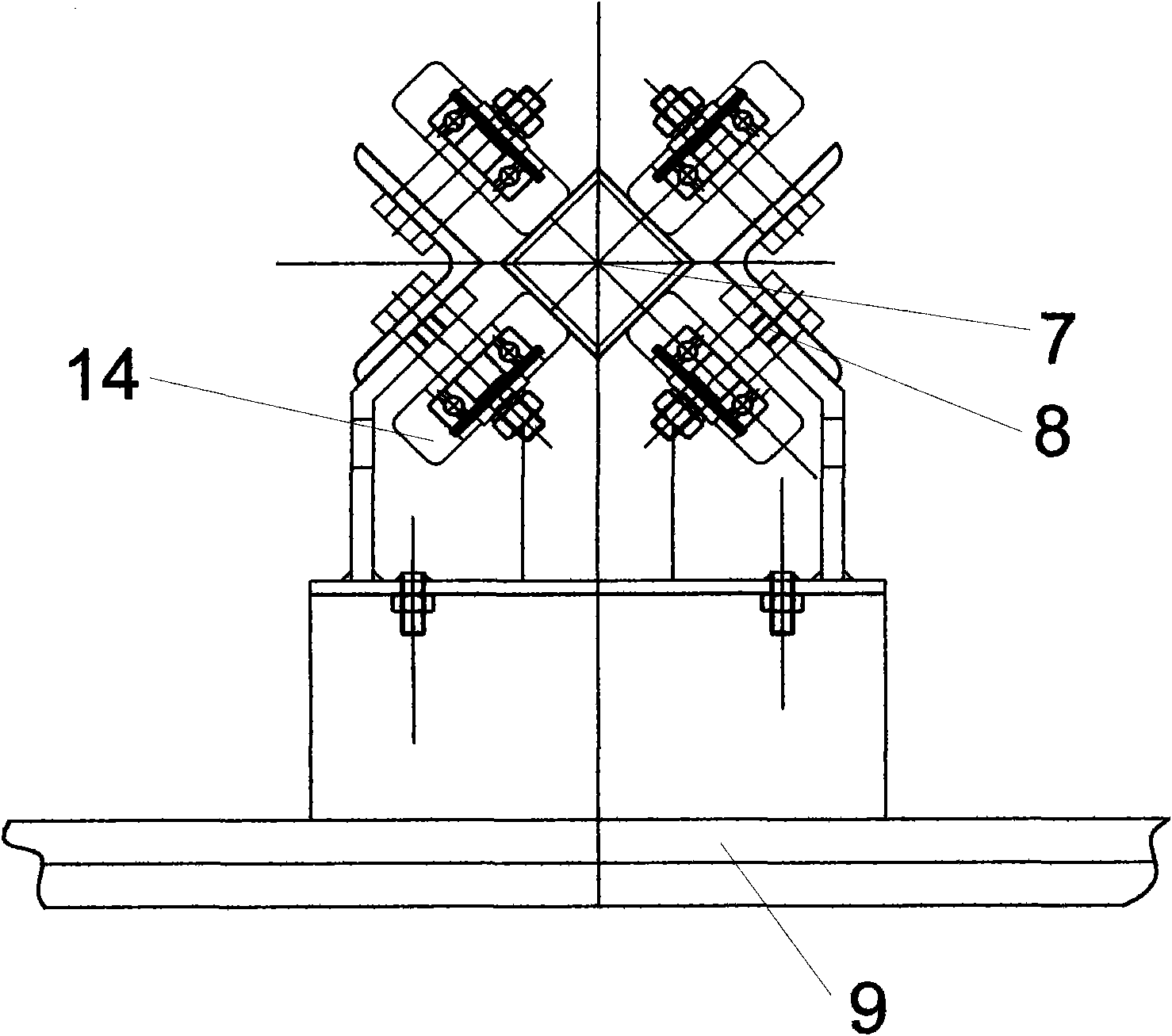

[0020] Depend on Figure 1-3 As shown, the present invention's figure 1 The closed circular track in the closed circular track 1 is fixedly arranged in the tower near the air cooler 13 of the indirect air cooling unit (such as figure 2 Shown) on the position; on the circular track 1, a walking truss 4 with a walking drive device 2 is provided, and the walking driving device 2 includes: a driving device for the walking truss to move along the circular track and a steering for the walking truss to move along the circular track Device; a vertical frame 5 that moves horizontally along the vertical direction of the track is arranged on the walking truss 4, and a guide limit mechanism 6 of the vertical frame 5 is also arranged on the walking truss; a vertical moving guide rail is arranged on the vertical frame 5 7. On the vertical moving guide rail 7, a vertical traveling mechanism 8 (such as image 3 shown), a vertical drive mechanism 3; a cleaning mechanism 9 is also arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com