Rotor online automatic balancing device of high-speed rotating machine

A high-speed rotation and automatic balancing technology, applied in the direction of balancing the rotating body, etc., can solve the problems of inability to use high-speed rotating machinery, the minimum adjustment angle is too large, the safety accident of the adjustment disc, etc. Adjustable effect of weight capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

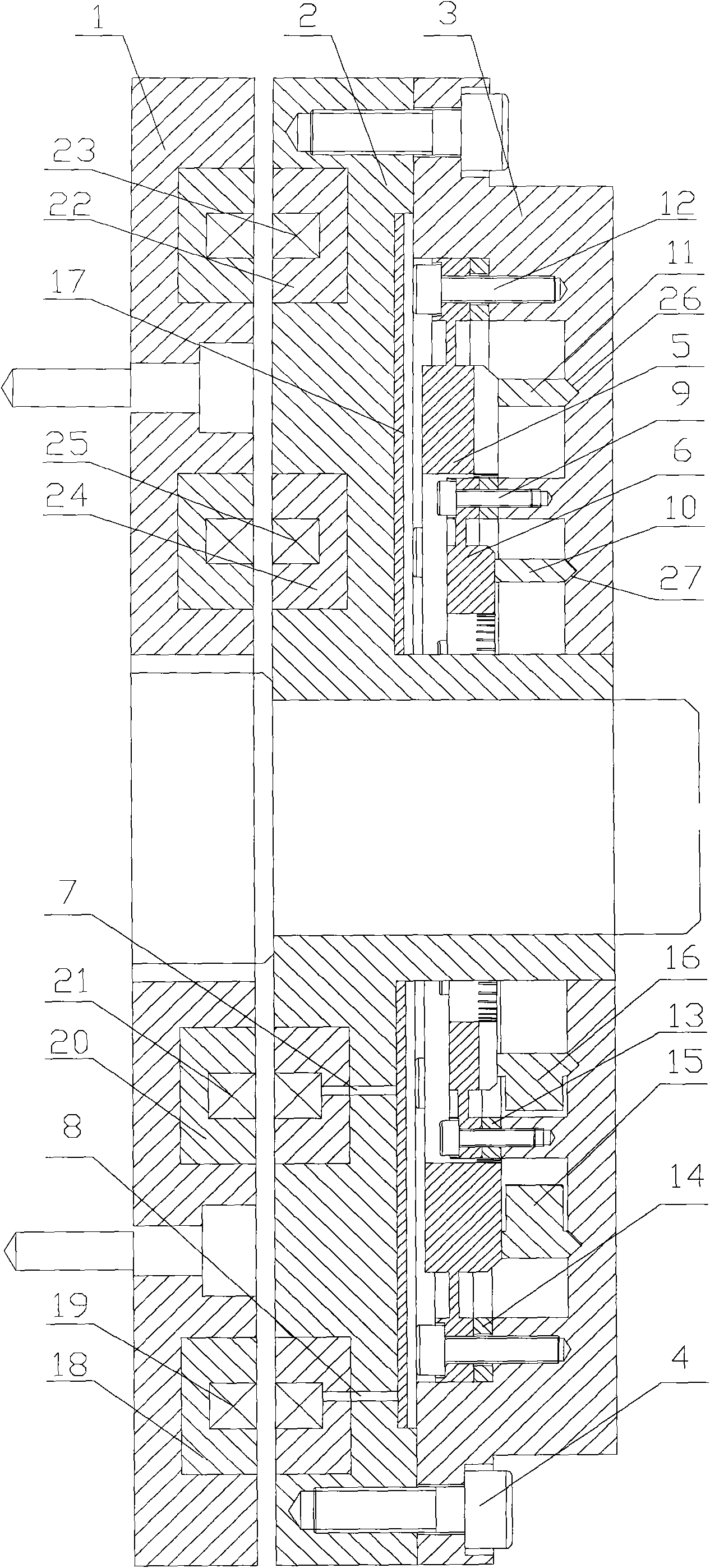

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033]An online automatic balancing device for a rotor of a high-speed rotating machine, characterized in that it includes a static disk (1), a moving disk (2) and a moving disk end cover (3); the static disk (1) is installed on the rotor end cover , the right end surface of the static disk (1) is provided with an annular groove, and a primary induction transformer is arranged in the annular groove; the left end surface of the moving disk (2) is provided with an annular groove, and a secondary induction transformer is arranged in the annular groove stage induction transformer; the moving disk (2) is installed on the high-speed rotor, and the moving disk end cover (3) is fixed on the moving disk (2) by screws; the outer fixed ring (5) in the moving disk (12) Fixedly installed on the moving plate end cover (3), an outer ring adjusting gasket (14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com