Method for drilling vacuum glass

A vacuum glass and glass hole technology, applied in glass forming, glass remolding, glass manufacturing equipment and other directions, can solve the problems of reducing the application field of vacuum glass, affecting the development of vacuum glass, losing the characteristics of vacuum glass, etc. performance and stability, flexible hole-making methods, and the effect of improving the appearance of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

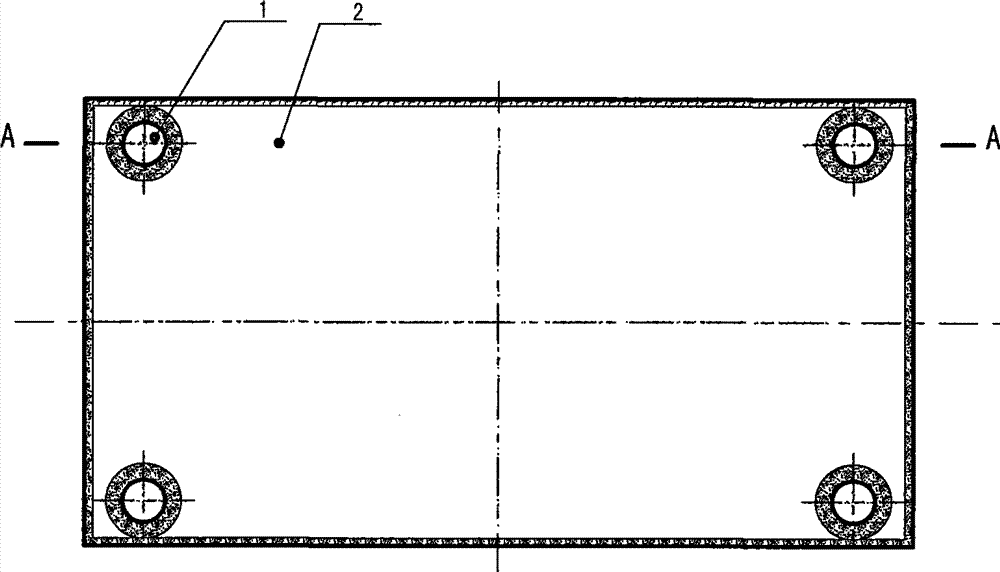

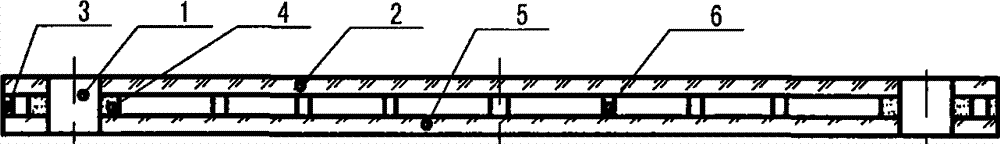

[0026] Example 1: see figure 1 , figure 2 , Figure 5 , Figure 7 .

[0027] A hole-making method for vacuum glass, comprising setting a support 6 on a substrate glass 5, merging the substrate glass and an upper glass 2 and setting an edge sealing 3, heating in a heating furnace, vacuuming and sealing, the above-mentioned It is prior art, so this embodiment does not describe in detail.

[0028] The innovation of the present invention is: the glass inner hole 1 is made in advance on the corresponding position of the substrate glass and the top glass, or as Figure 5 Groove-shaped side holes 8 and semicircular side holes 9 are made as shown (glass inner holes and side holes can also be through holes of other shapes); The holes are edge-sealed with low-melting-point glass powder 4, and after being heated by a heating furnace, a low-melting-point glass powder sintering zone can be formed to seal the holes to ensure the vacuum degree of the vacuum glass.

[0029] In order to...

Embodiment 2

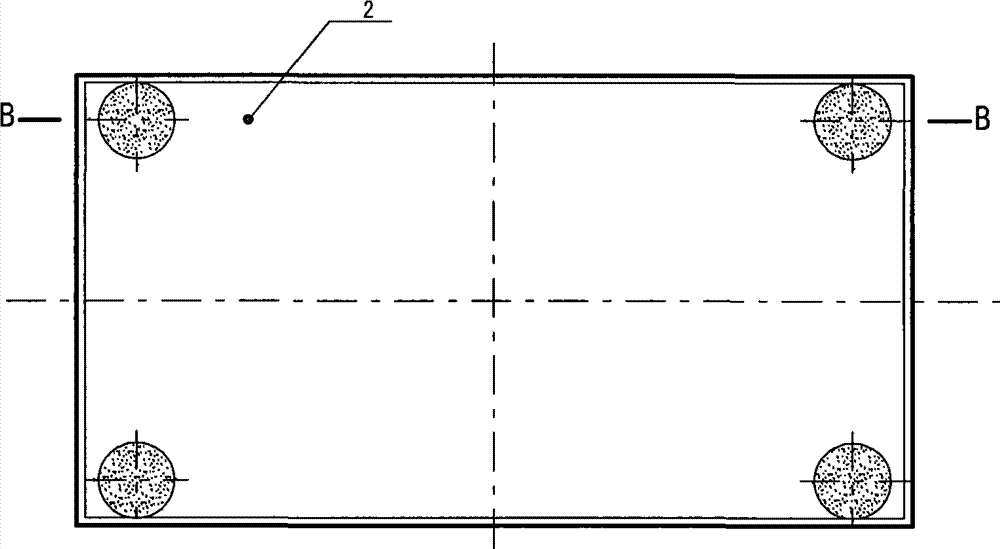

[0030] Example 2: see image 3 , Figure 4 , Image 6 , Figure 8 .

[0031] A hole-making method for vacuum glass, the prior art of which is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com