High purity silicon production device and preparation method thereof

A high-purity silicon powder and high-purity technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high-purity silicon purity and performance reduction, increase in high-purity silicon production costs, high-purity silicon pollution, etc. , to achieve the effect of improving quality, reducing production cost and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

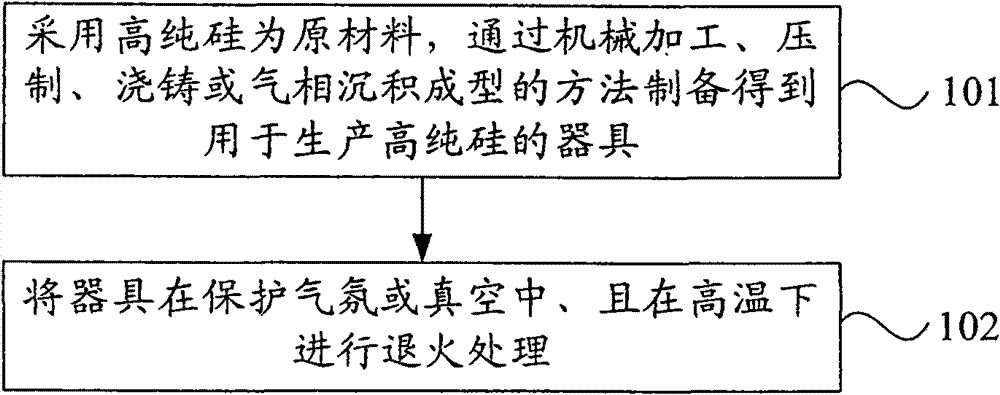

[0017] figure 1 It is a flowchart of Embodiment 1 of the preparation method of high-purity silicon production equipment of the present invention, such as figure 1 As shown, the method includes:

[0018] Step 101, using high-purity silicon as a raw material to prepare a device for producing high-purity silicon by machining, pressing, casting or vapor deposition molding.

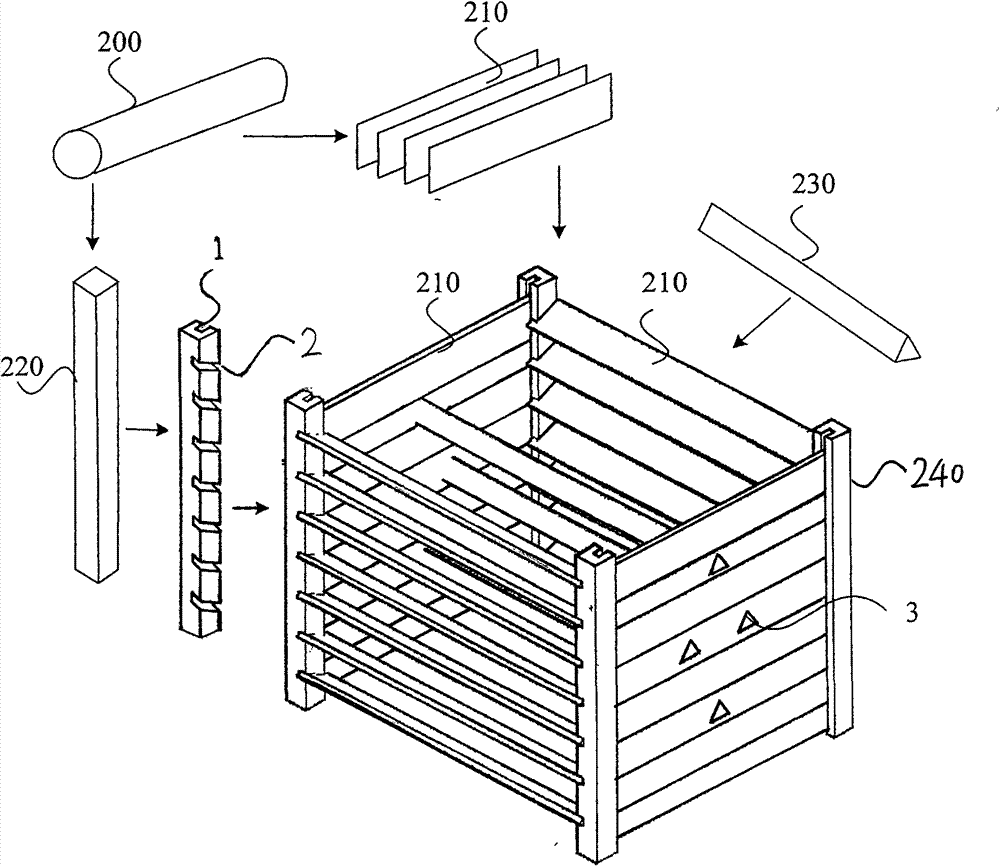

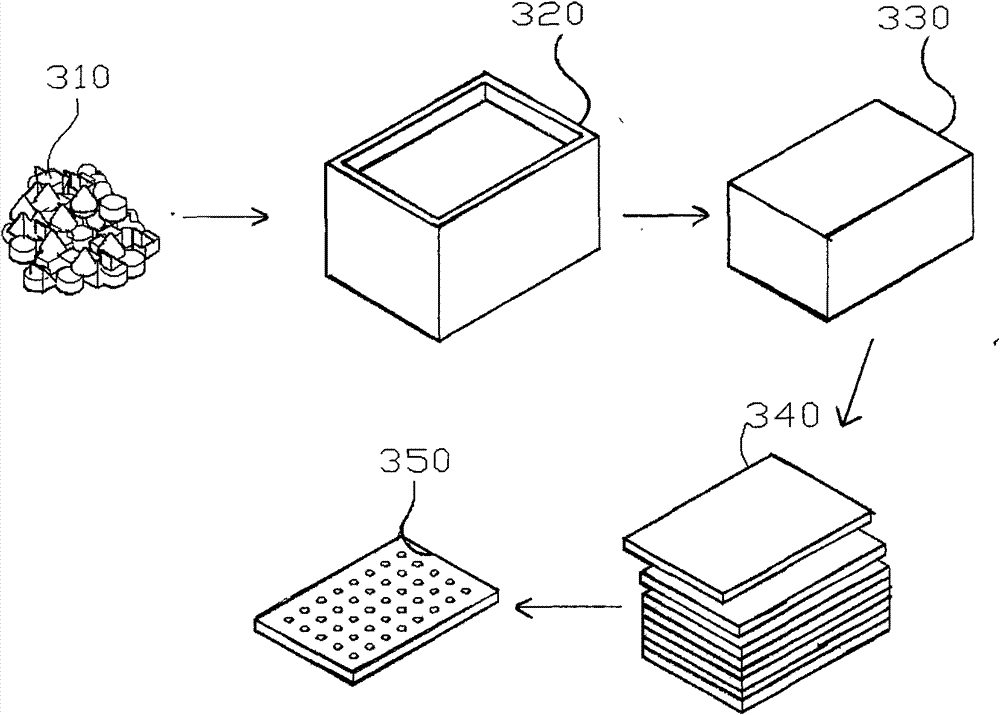

[0019] Among them, high-purity silicon in different forms can be used as raw materials, such as high-purity silicon in rod form, granular form, block form or powder form, or through high-purity silicon-containing gas (for example: trichlorosilane , silane or silicon tetrachloride, etc.) to form high-purity silicon by vapor deposition. According to the different appliances to be prepared, choose high-purity silicon in different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com