Rotating speed adjustment method in asynchronous motor direct torque control system

A technology of direct torque control and adjustment method, which is applied in the field of control, can solve the problems that fast tracking performance and strong anti-disturbance ability cannot be achieved at the same time, and achieve the effect of improving fast tracking performance, starting performance and anti-disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

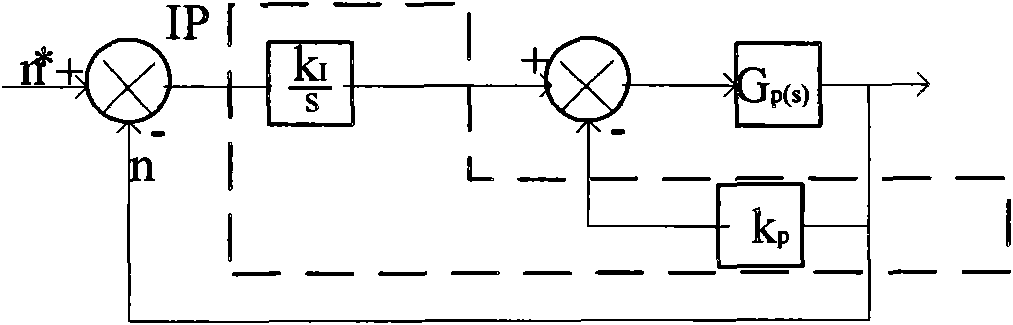

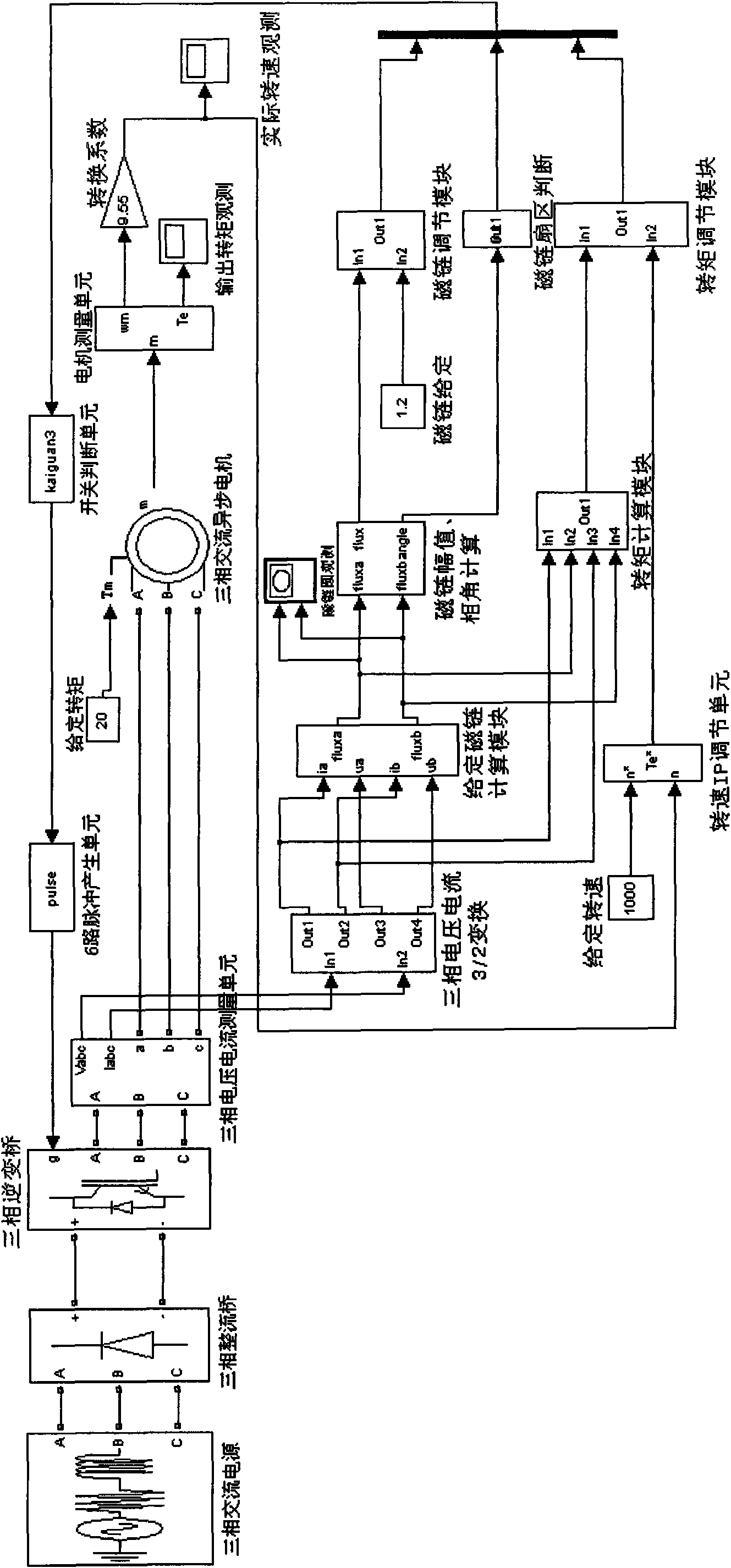

[0012] Such as figure 1 As shown in the IP control closed-loop control principle diagram, the proportional control link in the traditional PI controller is moved from the forward channel to the feedback channel, and a new type of IP controller is formed through structural changes.

[0013] The closed-loop transfer function of the IP control system is: G b(s) =k I G p(s) / [k I G p(s) +(1+k p G p(s) )s] In the above formula: G p(s) , G b(s) Represent the transfer function of the controlled object and the transfer function of the closed loop; k p is the proportional gain, k I Integral gain, there is no zero point in the closed-loop transfer function of the IP control system. Since the proportional link is moved to the feedback channel, the IP control first plays an integral role and then a proportional role, and the overshoot will be reduced or even disappeared.

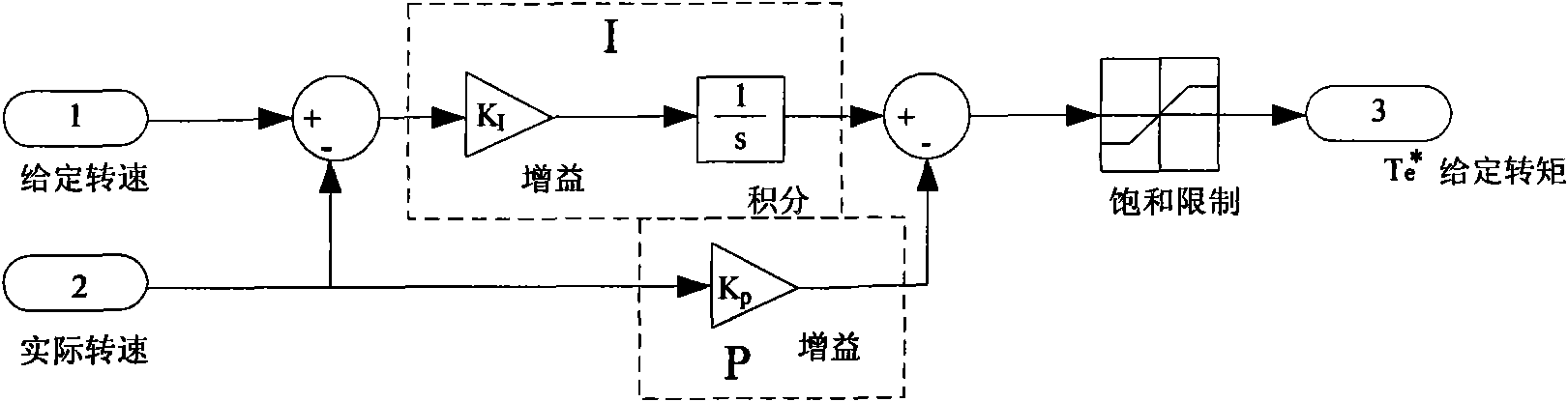

[0014] figure 2 It is the structure diagram of IP controller. The IP structure is used in the figure, 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com