Side cover plate type cable bridge frame

A technology for cable trays and side covers, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of labor and money, labor and time, and achieve the effect of optimizing the installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

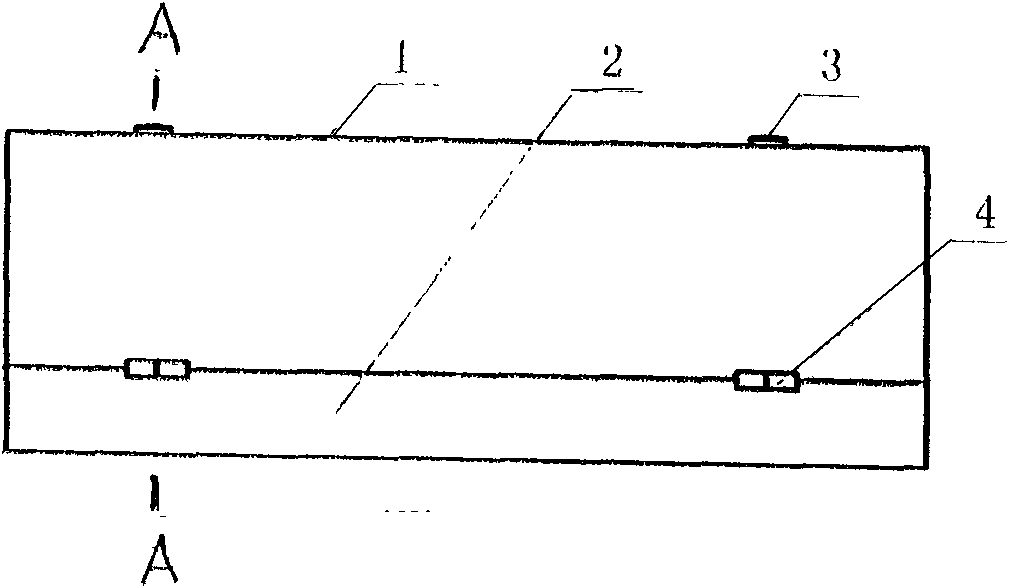

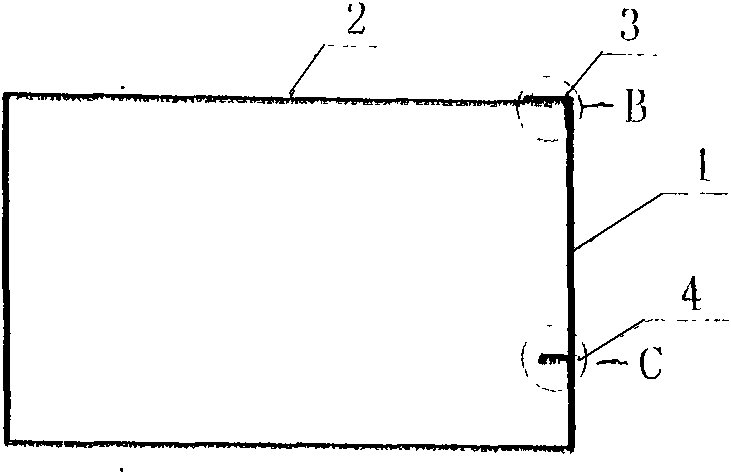

[0016] refer to figure 1 , Fig. 2, the present invention is a kind of side cover plate type cable tray, and this bridge frame is provided with the trough body 2 that section is " G " shape, and a section is set on the notch of trough body and is the side cover plate 1 that section is " U " shape .

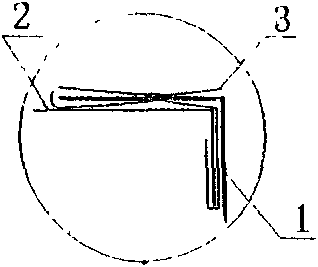

[0017] When concretely implementing the present invention, at first the steel plate is folded by the machine "G" shape bridge tank body 2 and "U" shape side cover plate 1, and the upper and lower notches of the tank body 2 are respectively provided with 90° folded inwardly. Degree of strengthening edge. In addition, a commercially available elastic snap lock 3 is provided between the upper side of the side cover and the upper notch of the tank body 2 , and a hinge 4 hinged to each other is provided between the lower side of the side cover 1 and the lower slot of the tank body 2 .

[0018] like Image 6 , during the installation process, the cable tray 5 can be shelved on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com