Construction method for pneumatic tamping pipe of horizontal frozen hole on metro bypass

A construction method and bypass channel technology, which are used in infrastructure engineering, soil protection, pipeline laying and maintenance, etc., can solve problems such as poor engineering safety, stratum disturbance, and more water and sand gushing, and achieve low equipment use costs and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those of ordinary skill in the art to clearly understand the specific technical solutions of the present invention, it will now be further described in detail in conjunction with the embodiments and accompanying drawings:

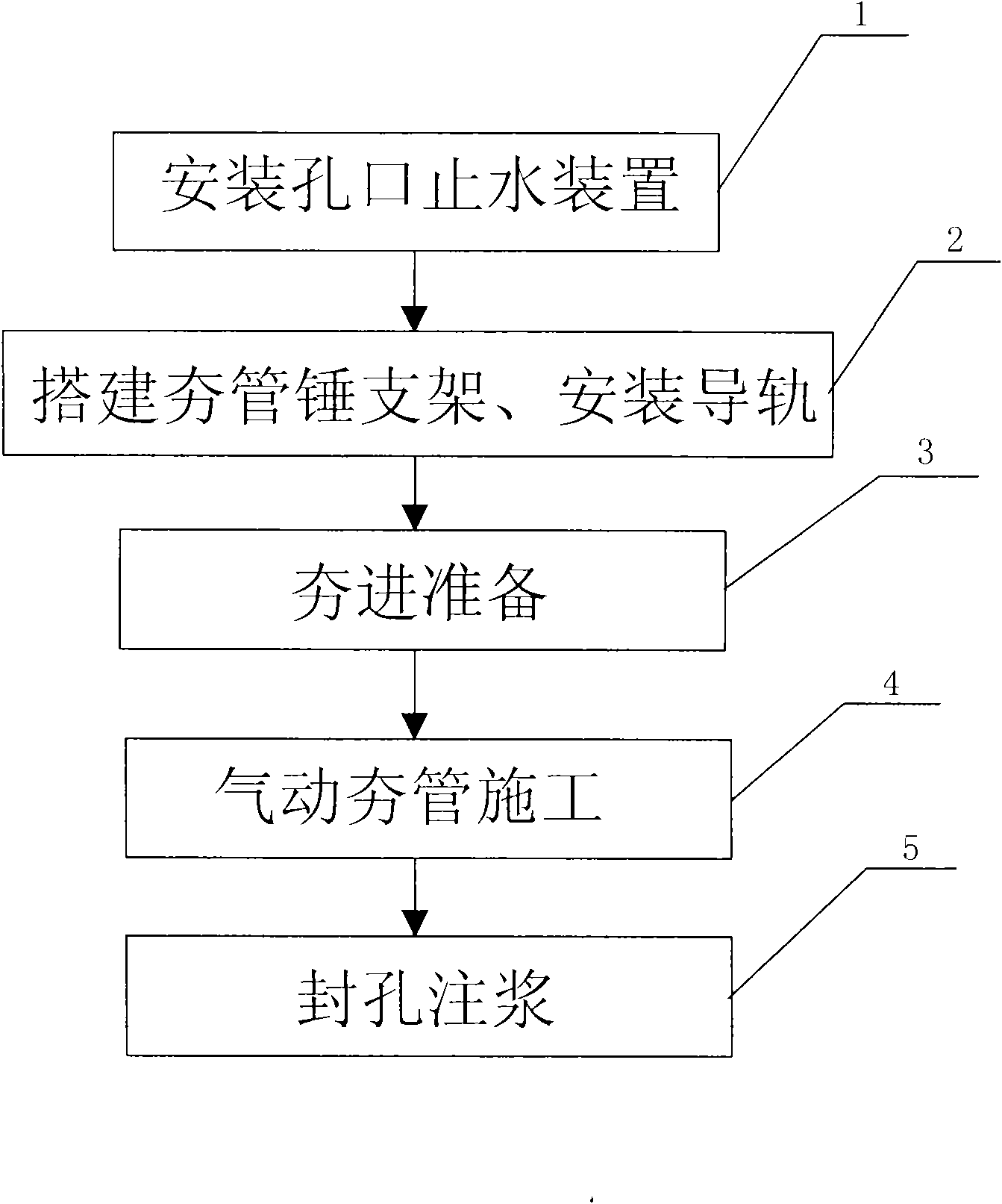

[0035] A pneumatic ramming pipe construction method for horizontal freezing holes in subway side passages, such as figure 1 shown, including the following steps:

[0036] Step 1: Install the orifice water stop device 90, such as Figure 4 shown;

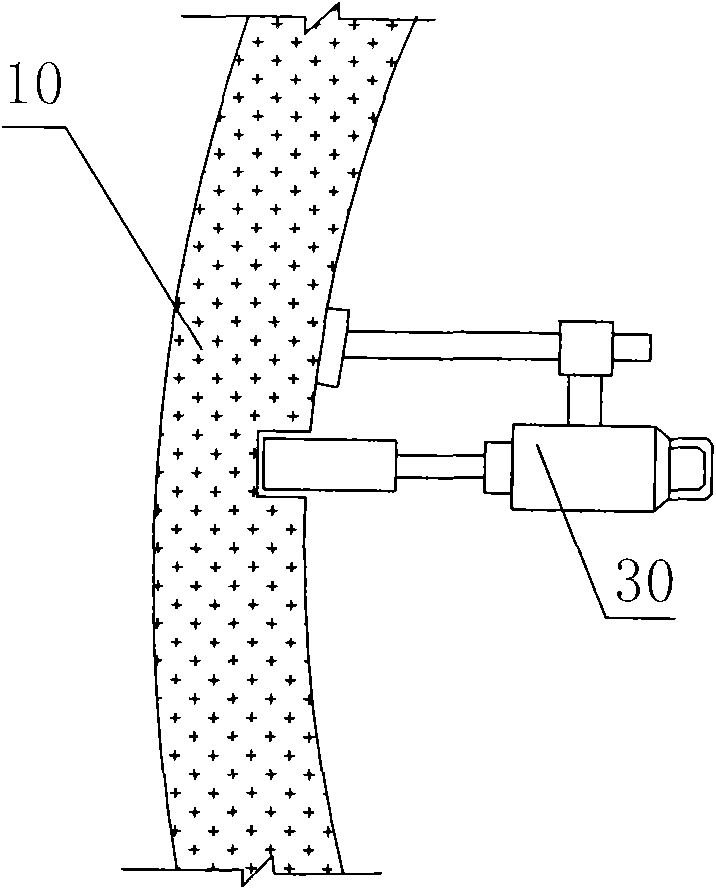

[0037] (1) Utilize the drilling machine 30 that diameter of drill bit is φ 120mm to carry out the first drilling on segment 10, and drilling depth is about 250mm, as figure 2 shown;

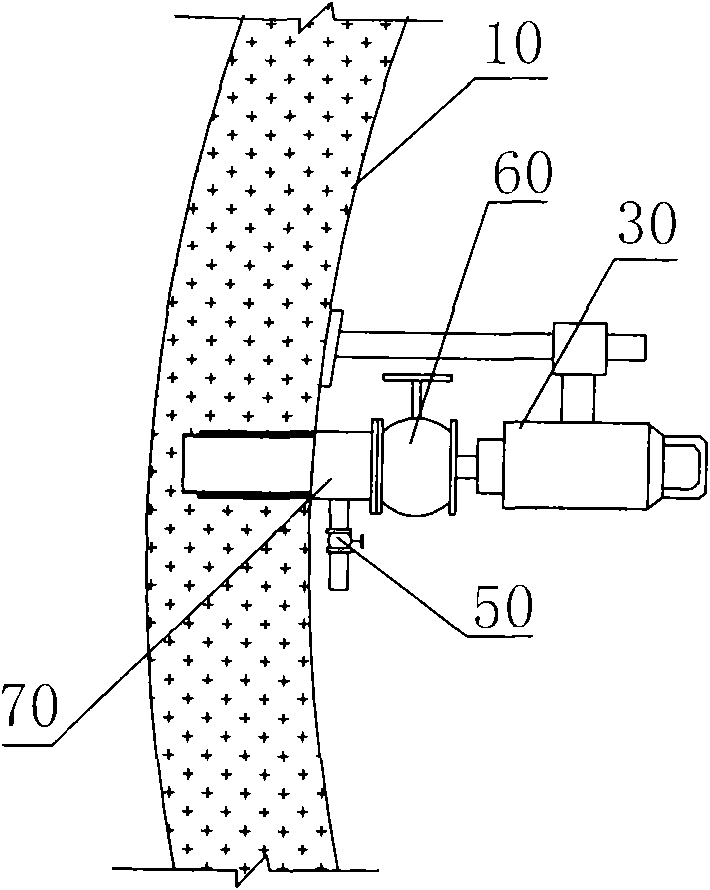

[0038] (2) Carry out orifice pipe 70 embedding in the hole that opened for the first time, the fish scale buckle of orifice pipe before embedding of orifice pipe 70 must be tightly wound with hemp silk, after embedding, its periphery uses four expansion screws and concrete pipe The sheet 10 is firmly fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com