System and method for compensating maximum output power of switching power supply

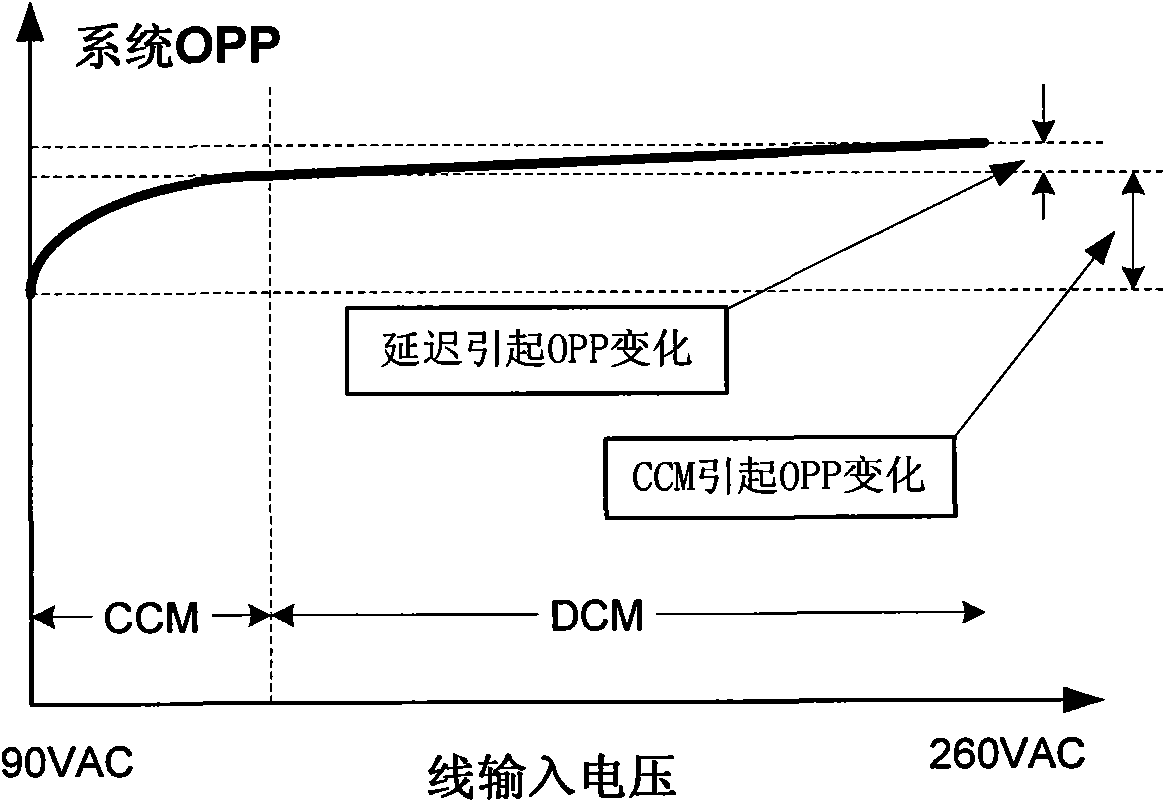

A technology of maximum output power and switching power supply, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the phenomenon of OPP recovery gap increase, deterioration of sub-harmonic oscillation and large and small waves , system startup failure and other problems, to achieve the effect of overcoming periodic OCP compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] refer to Figure 8 , as an embodiment of the present invention, the processing module 31 in the above-mentioned overcurrent protector 3 includes:

[0063] A cyclic pulse generator 311, configured to generate several pulse signals (K1-Kn) and a clear signal CLR according to the PWM signal;

[0064] A clearing integrator 313, which generates a signal X0 according to the PWM signal and the clearing signal CLR output by the cycle pulse generator 311;

[0065] A sample-and-hold array 3121 and an arithmetic unit 3122, the sample-and-hold array 3121 is used to sample the duty cycle or pulse on-time of the several pulse signals (K1-Kn) to obtain several sampling signals (X1-Xn) , the operation unit 3122 performs operation processing on the sampling signal (X1-Xn) and the signal X0 output by the clearing integrator to generate a compensation signal Vcomp; specifically, the sample-and-hold array includes several groups of sampling units S1 / C1, S2 / C2 ,..., Sn / Cn, wherein S repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com