Optimized design method of membrane bioreactor system

A membrane bioreactor, a technology of optimized design, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem that the results are easy to be theoretical, lack engineering data verification, and fail to meet engineering specifications and other problems, to achieve good economic benefits, save investment, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] To treat water Q = 2000m 3 / d MBR reactor optimization design process as an example.

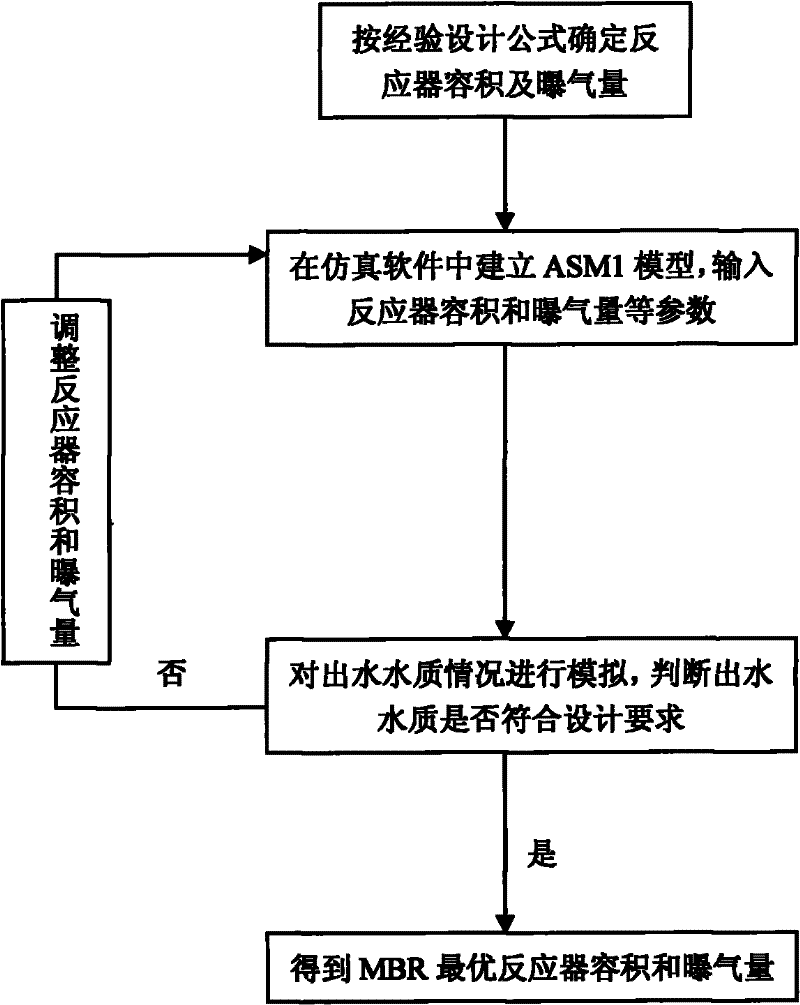

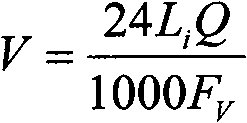

[0030] Step 1, measuring the water quality parameters of the influent, and calculating the volume of the membrane bioreactor and the gas supply of the aeration tank according to the empirical formula and empirical parameters;

[0031] See Table 1 for influent water quality and effluent standards (GB18918-2002 Class A standard);

[0032] Table 1 Influent water quality and effluent standard of MBR reactor

[0033] project

Influent water quality (mg / L)

Effluent standard (mg / L)

BOD 5

200

10

COD Cr

400

50

SS

250

10

NH 3 -N

35

5

TN

45

15

[0034] Compared with the effluent standard value, the smaller the effluent water quality parameter is, the better the effluent water quality is, but it is not conducive to the optimization of the membrane bioreactor system. Therefore, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com