Carrier with antiskid function

A technology of trucks and functions, which is applied in the field of trucks with anti-skid function, can solve the problems of insufficient driving force, slipping, and malfunction of trucks, and achieve the effects of short control response time, guaranteed anti-skid effect, and normal driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

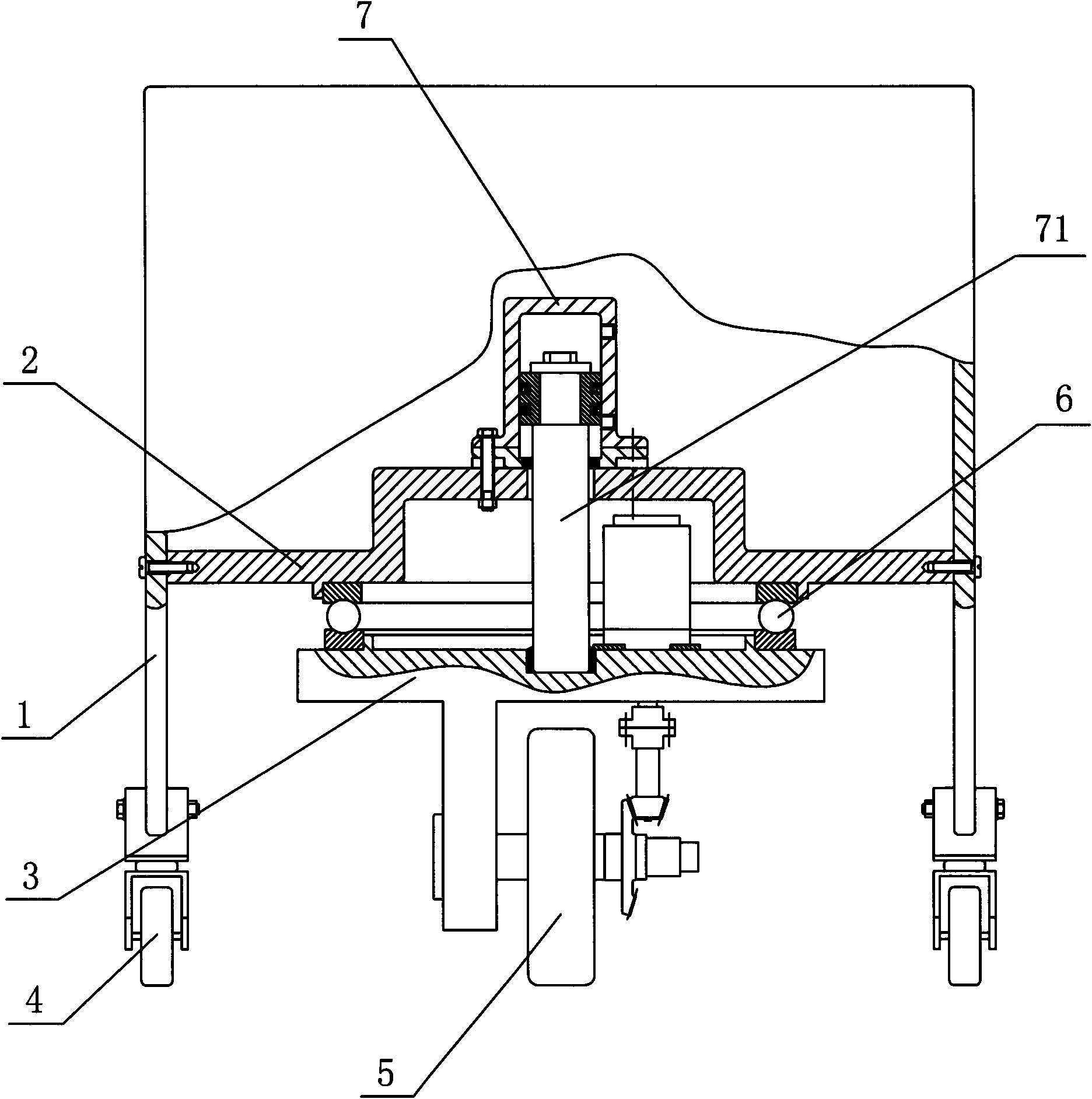

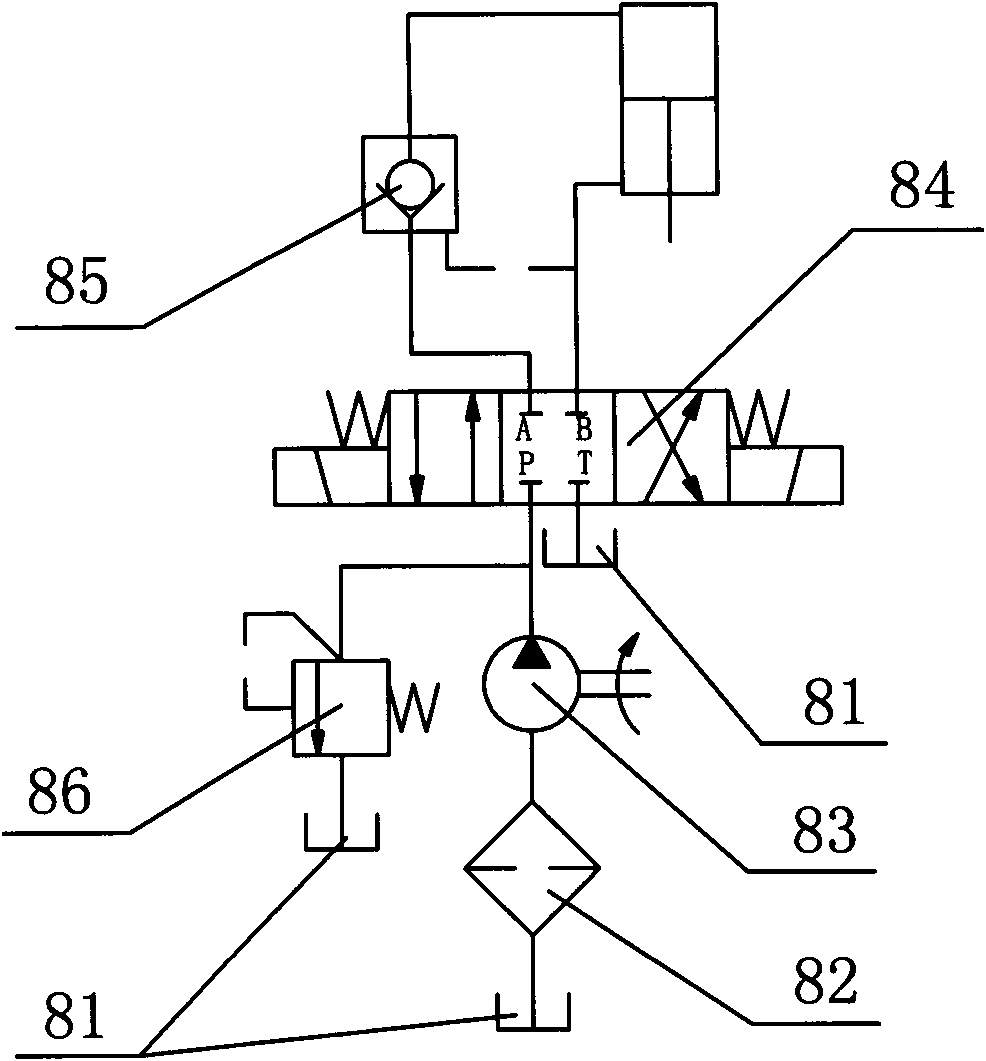

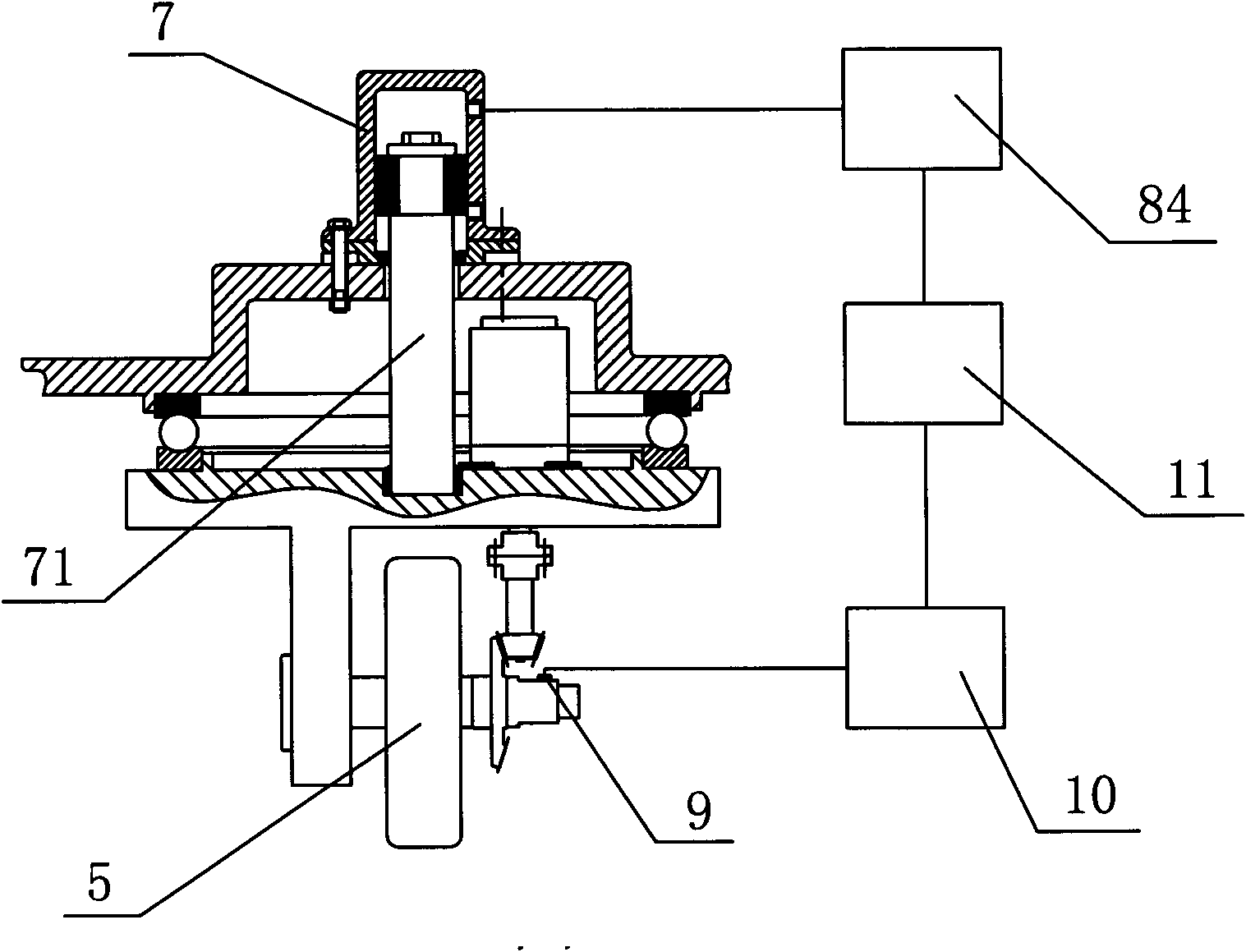

[0013] As shown in the figure, a truck with anti-skid function includes a bottom plate 2, a bracket 3, an outer plate 1, a speed sensor 9, a controller 10, a solenoid valve drive circuit 11, a hydraulic cylinder and a hydraulic servo drive connected to the hydraulic cylinder system, the base plate 2 and the outer plate 1 are vertically fixedly connected by screws, the lower end of the outer plate 1 is equipped with a universal wheel 4, the drive wheel 5 is installed on the bracket 3, and a steering wheel for the drive wheel 5 is arranged between the bracket 3 and the base plate 2. The thrust bearing 6, the hydraulic cylinder includes a cylinder block 7 placed in a vertical direction and a piston rod 71 sealed with the cylinder block 7, the cylinder block 7 is fixed on the bottom plate 2 by screws, and the end of the piston rod 71 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com