Adhesive patch

A patch and adhesive layer technology, which is applied in viscous dressings, medical science, dressings, etc., can solve the problem of low adhesive patch and drop, and achieve the effect of reducing the frequency of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

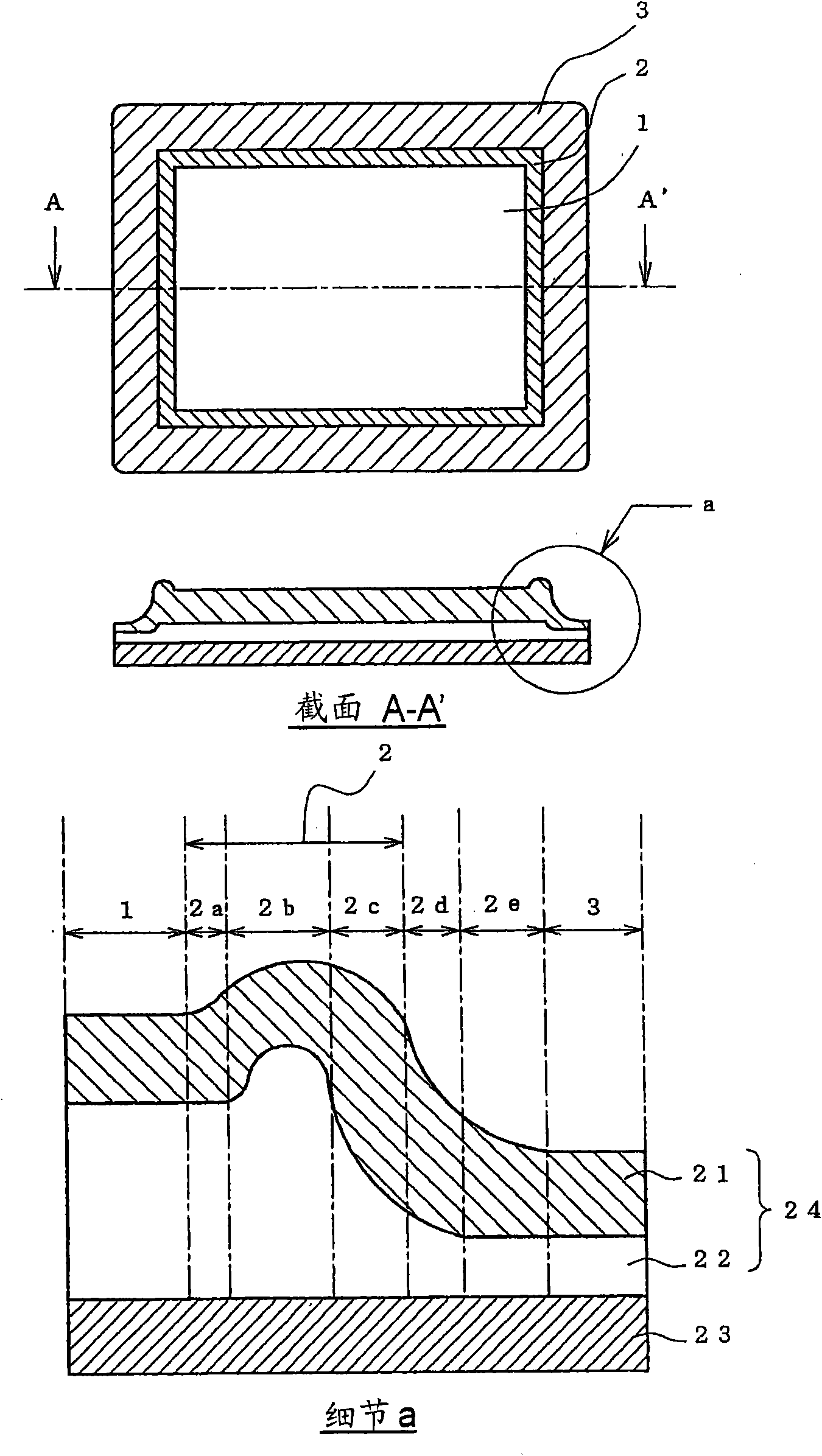

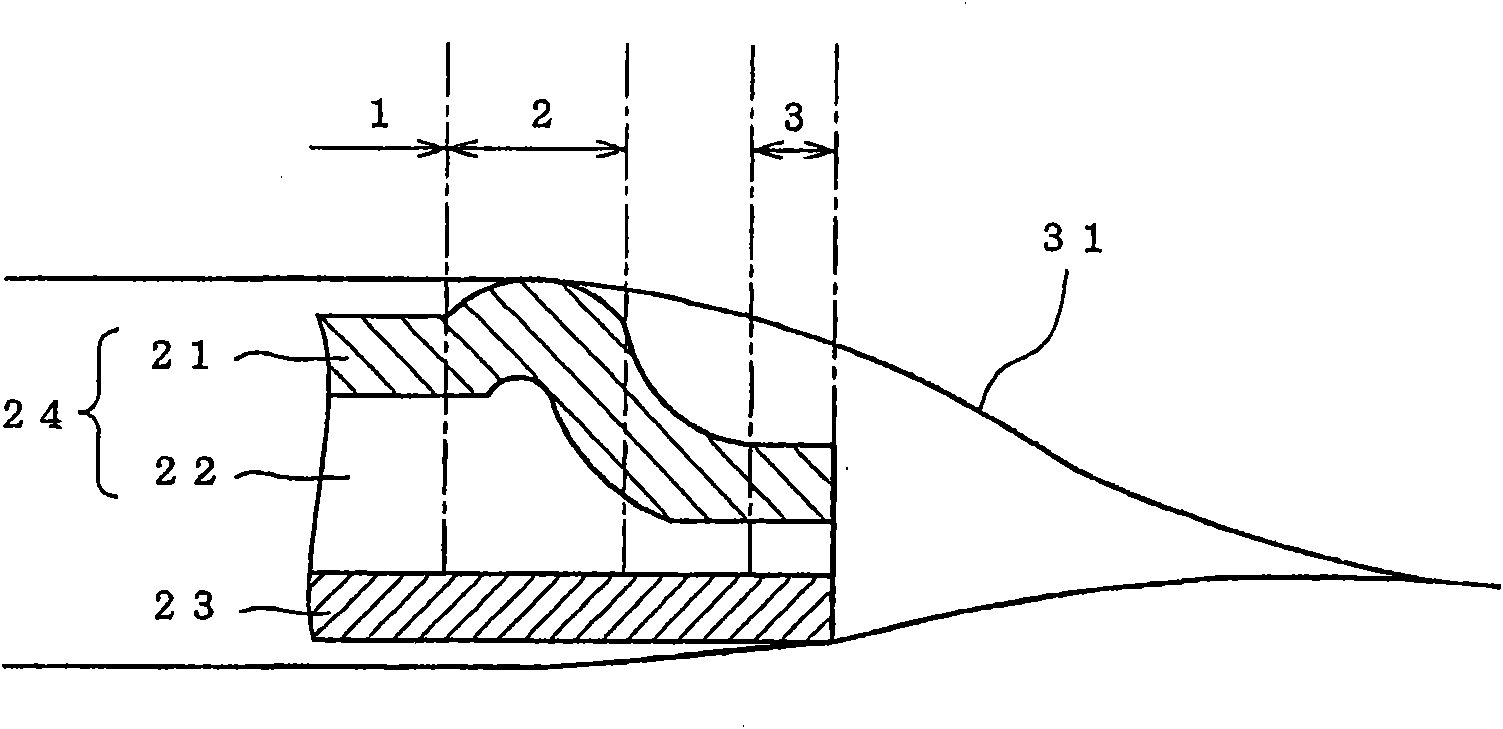

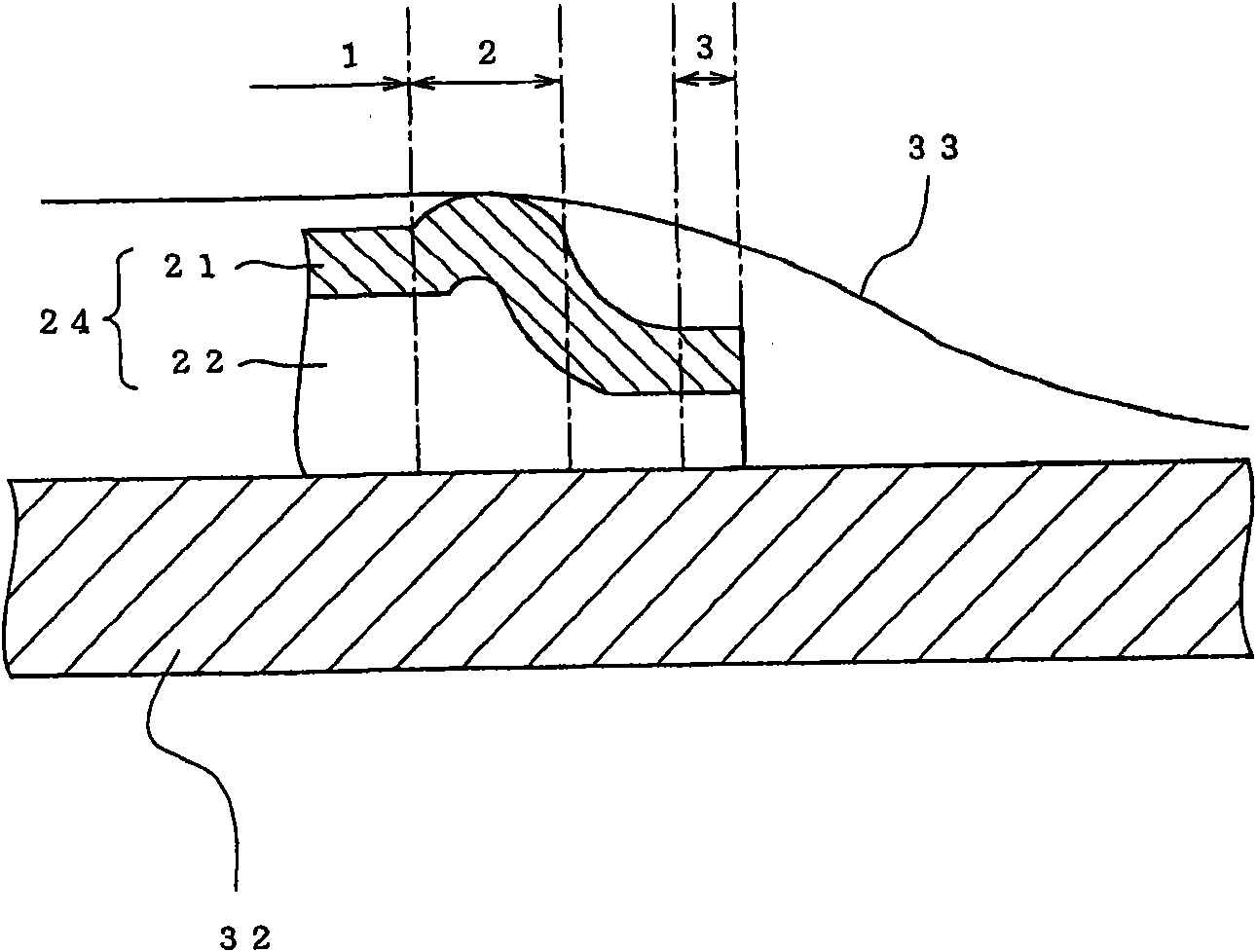

Image

Examples

Embodiment 1-7

(1) Preparation of composition for hard adhesive layer formation

High molecular weight polyisobutylene (viscosity average molecular weight 4x10 6 ), medium molecular weight polyisobutylene (viscosity average molecular weight 5x10 4 ), tackifier (alicyclic saturated hydrocarbon resin, softening point 141°C (ring and ball method)) and organic liquid component (isopropyl myristate) in a weight ratio of 17:25:28:30 (total weight 7.5 kg) was mixed in the presence of a toluene / hexane mixed solution (weight ratio 1:1, 17.5 kg) to obtain a composition for forming a hard adhesive layer (total weight 25 kg).

[0090]

(2) Preparation of composition for soft adhesive layer formation

A composition for soft adhesive layer formation was obtained in the same manner as preparing the composition for hard adhesive layer formation, except that the above weight ratio was set to 14:28:28:30.

[0091]

The composition for forming a hard adhesive layer or the composition for forming a so...

Embodiment 8

Adhesive patches were produced in the same manner as in Examples 1-7 to obtain adhesive patch packages, except that by adjusting the size difference in the male type and female type of the pressure cutter module, the adhesive was die-cut out separately. The patch main part and the release liner are then die-cut to form outside the extension of the release liner in the entire edge portion of the adhesive patch main part.

[0094]

experiment example 1

Experimental Example 1 (Evaluation of Adhesive Patch Shape)

The adhesive patch was stained with an aqueous solution of ruthenic acid, and cut with a cryostat (LR-85 produced by YAMATOKOHKI INDUSTRIAL CO., LTD.). PET film and PET nonwoven fabric were measured by FE-SEM (Hitachi, S-4800) at a magnification of 50-1000 times to obtain a cross-sectional view, and read out the scales of the edge part, middle part and center part thickness, and the thickness of the main part of the adhesive patch (the sum of the thickness of the adhesive layer and the thickness of the support). In this case, there were depressions and protrusions on the surface of the PET nonwoven fabric. 10 protrusions were randomly selected in the cross-sectional image, and the average value of the thickness of the PET nonwoven fabric at the protrusions was calculated and taken as the thickness of the PET nonwoven fabric. Then, the thickness of the PET film and the thickness of the above-mentioned PET nonwoven fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com