Refinement production system and production method based on RFID and bar code fusion

A production system and production method technology, applied in the direction of collaborative operation devices, record carriers used by machines, instruments, etc., can solve the problems of high label costs and restrictions on the widespread use of RFID technology, to achieve accurate synchronization and improve product production quality , the effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

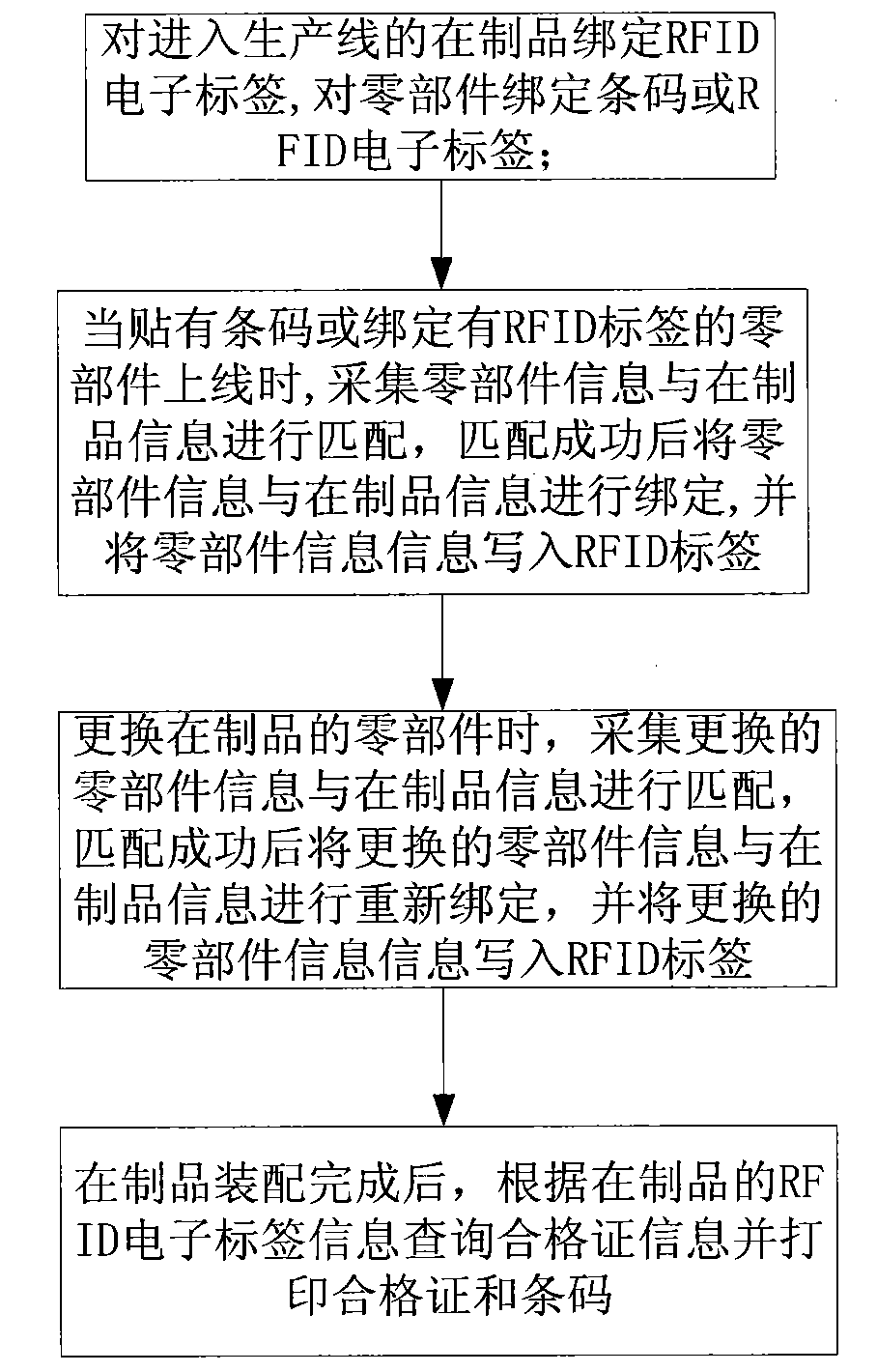

[0028] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

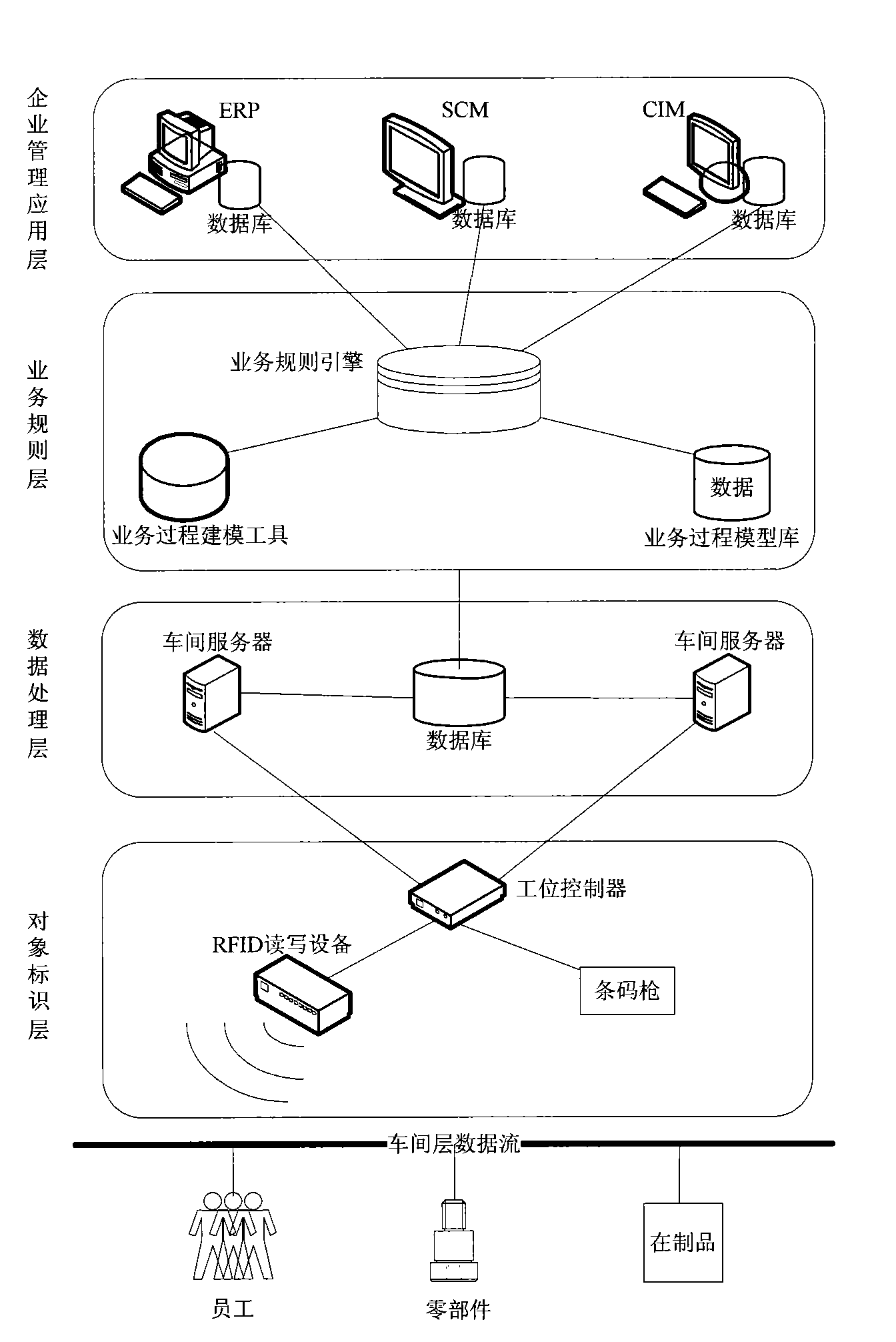

[0029] see figure 1 , the overall architecture of the discrete manufacturing enterprise using the refined production system based on the integration of RFID and barcode in this embodiment includes an object identification layer, a data processing layer, a business rule layer and an enterprise information management application layer, as follows:

[0030]Object identification layer: The object identification layer based on RFID and barcode collects production data, and through data preprocessing and analysis, realizes the identification of work in progress bound with RFID electronic tags and zero with barcodes or bound with RFID electronic tags. Parts are identified, tracked and controlled. Production data mainly includes information such as the status, parameters, and quantity of products in progress, parts, equipment, and personnel. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com