Light guide plate, backlight source and liquid crystal display device

A technology of liquid crystal display device and light guide plate, which is applied in the field of backlight source, can solve the problems that cannot be further improved, the brightness and uniformity of the light guide plate are limited, and the density of dots is limited, so as to reduce production costs and increase brightness and uniformity , Improve the effect of light guide efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

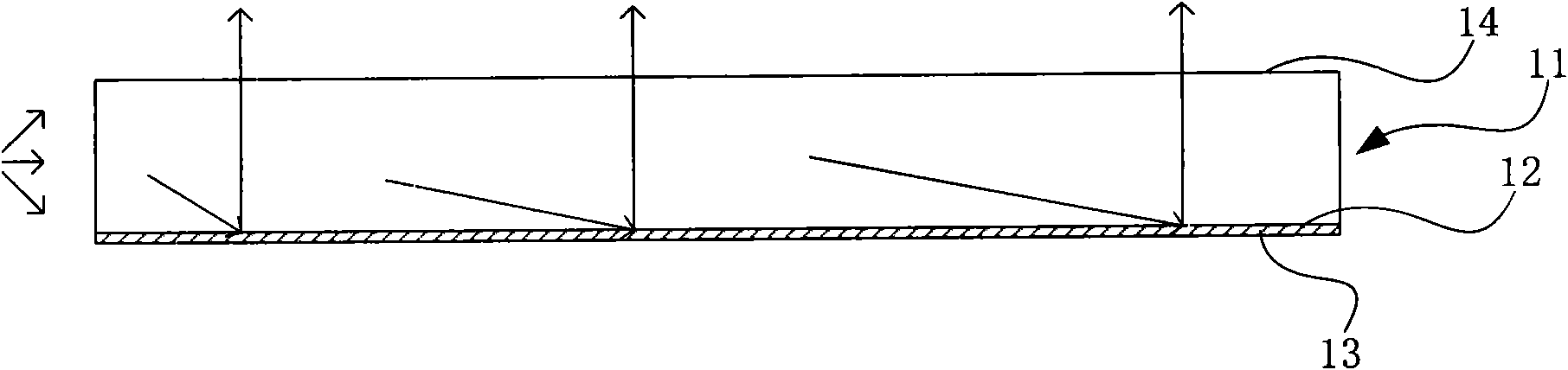

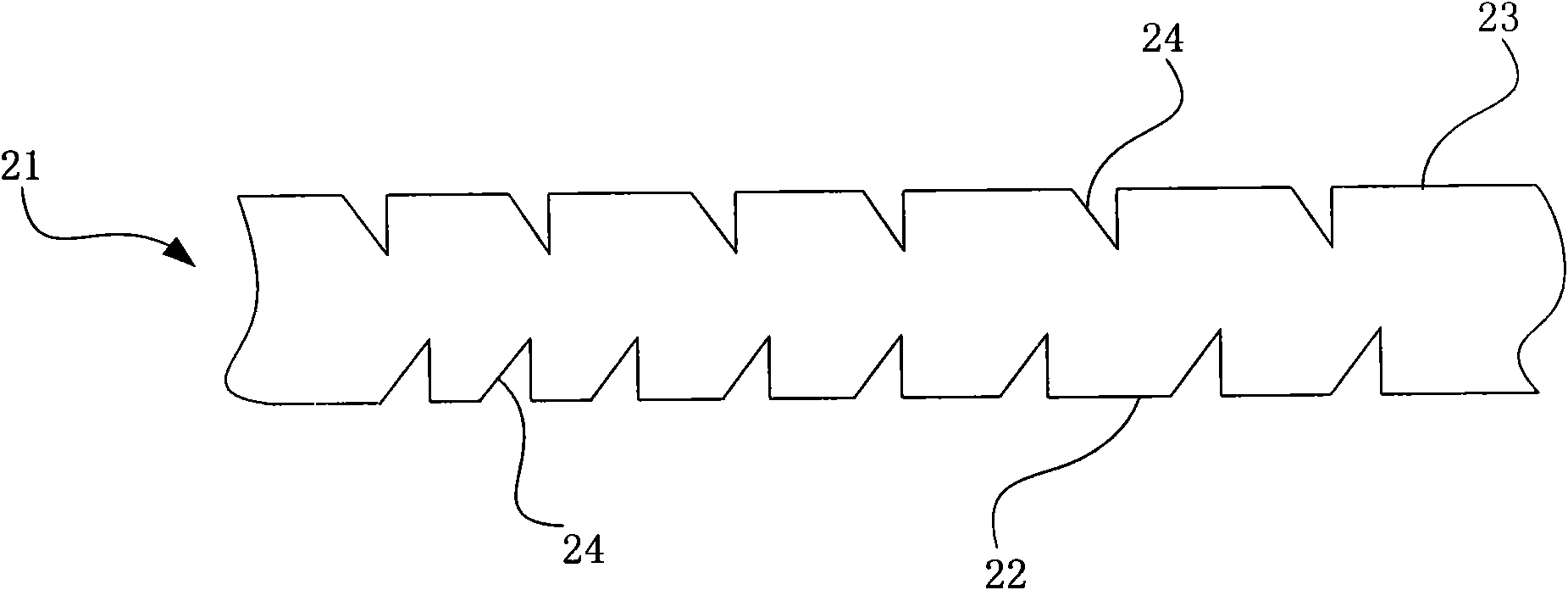

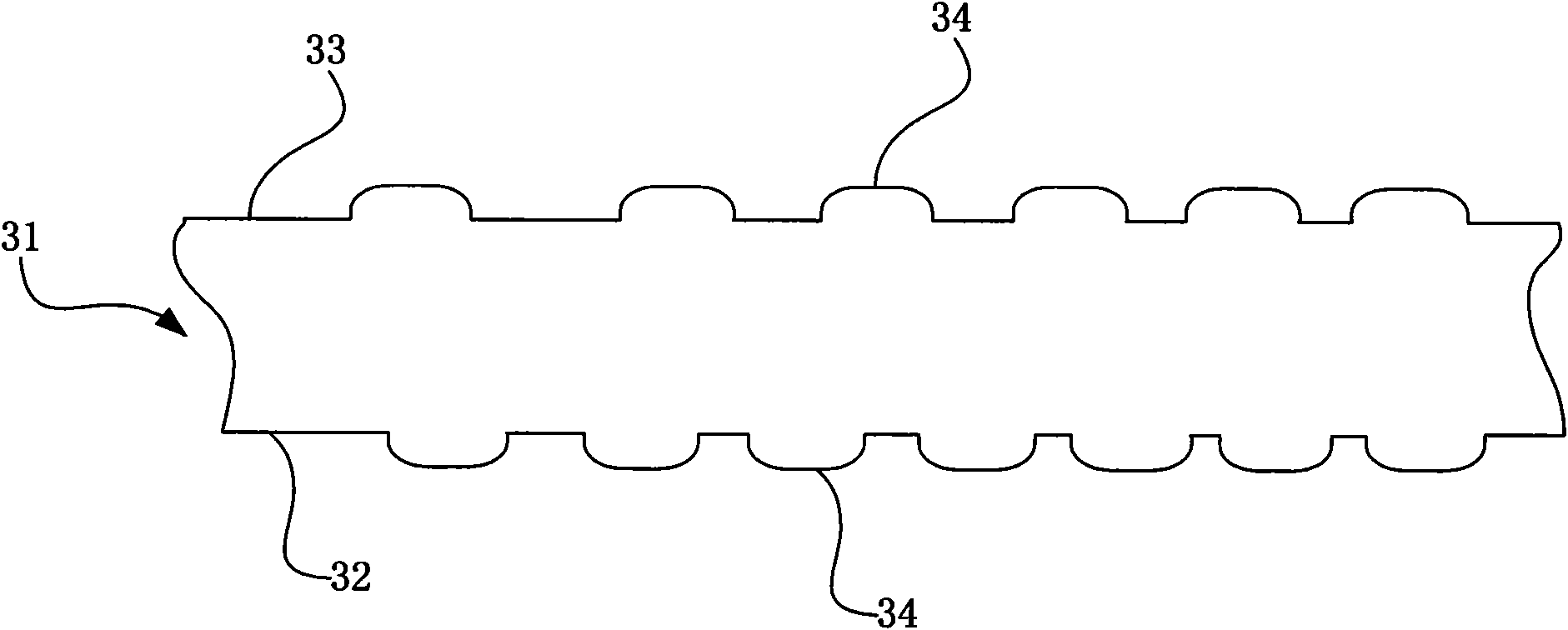

[0018] The light guide plate according to the embodiment of the present invention includes a top surface and a bottom surface, both of which are provided with microstructures. The dots of the microstructure can be truncated conical protrusions, ellipsoids, triangular pyramids, pyramids, V-shaped protrusions or grooves. The dots in these microstructures can be randomly arranged, or arranged in the order of density or gradually darker or shallower, or arranged in the order of density or gradually darker or shallower as a whole, and can be set randomly locally. Wherein, the randomly arranged positions are obtained through computer random algorithm calculation.

[0019] In this embodiment, the microstructure provided on the top surface of the light guide plate makes up for the lack of uniformity and brightness of the overall light guide plate by the microstructure on the bottom surface, thereby increasing the overall brightness, improving the efficacy of the overall uniformity and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com