Expansion assembly

A technology of assembly and expansion sleeves, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of wasting raw materials, increasing production costs, deformation of expansion sleeves, etc., and achieves the effect of convenient replacement and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

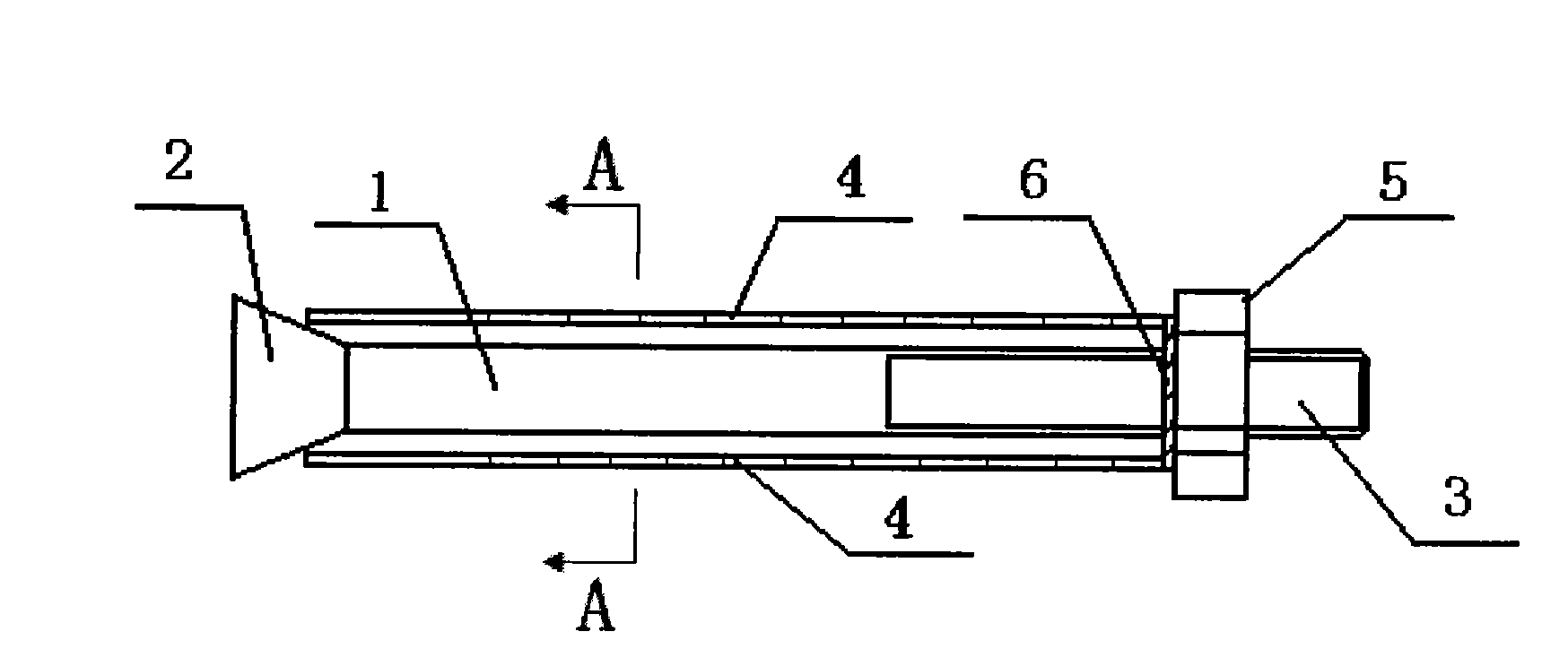

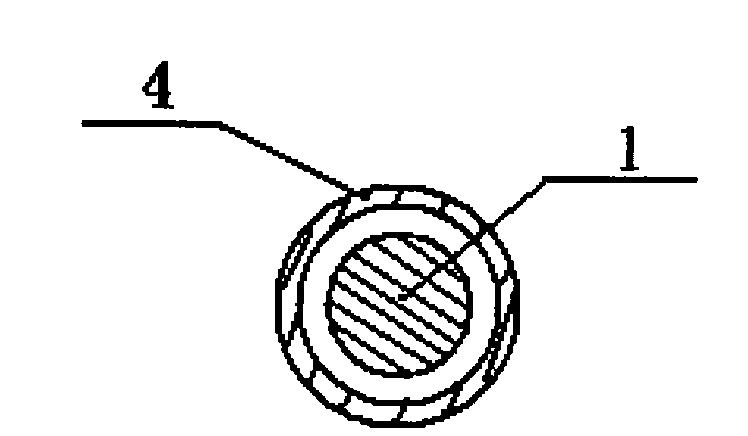

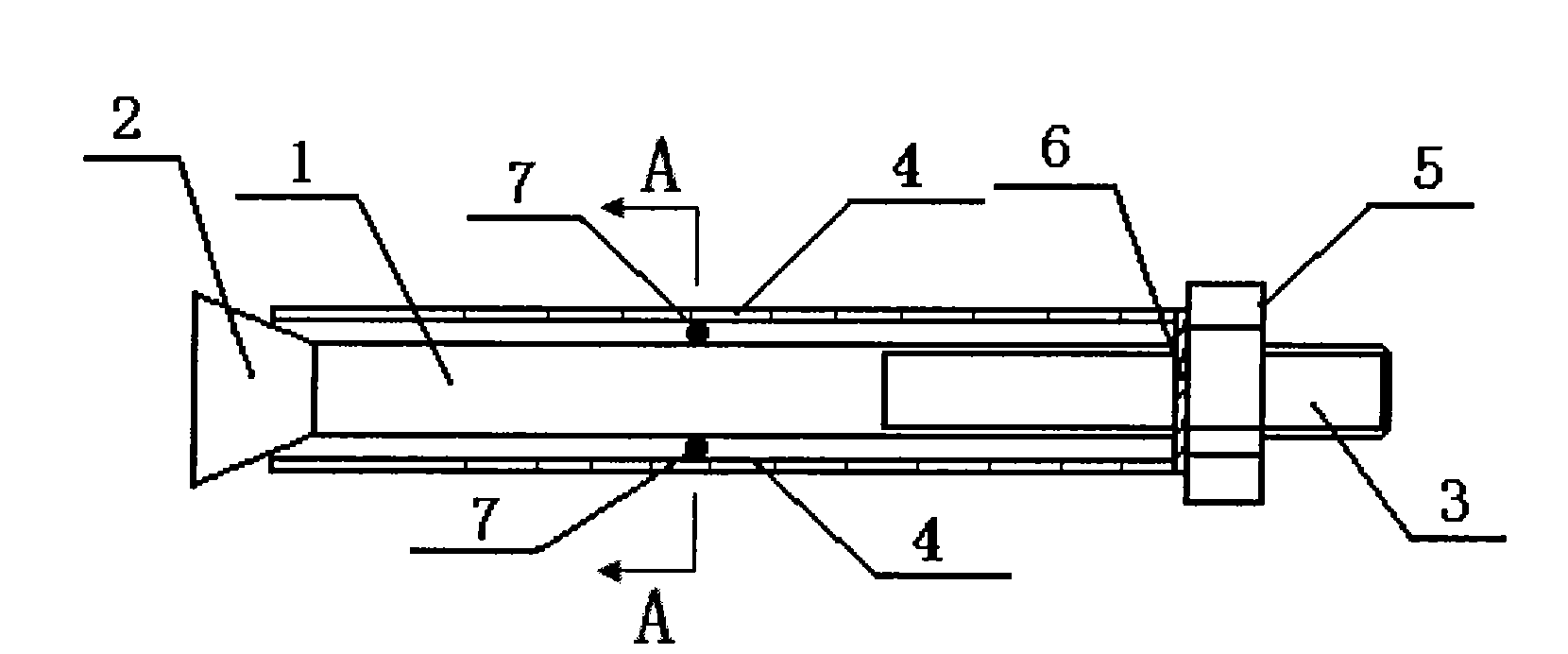

[0012] An expansion assembly, which includes a screw 1 with an inverted cone 2 at one end and a threaded segment 3 at the other end, a loop that is looped on the screw 1 and has a notch for its deformation and expansion Expansion sleeve 4, a nut 5 that is installed on the threaded section 3 of the screw rod 1 and can expand the expansion sleeve 4 during its rotation, and a washer 6 between the expansion sleeve 4 and the nut 5, which also includes an elastic ring 7 , the elastic ring 7 is looped on the screw rod 1 and is in contact with the inner wall of the expansion sleeve 4, and the elastic ring 7 is a rubber ring.

[0013] Of course, under the inventive concept of the present invention, the present invention has various implementation forms, which are all within the protection scope of the present invention for those skilled in the art who can reprod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com