Synthesis method of amino-protecting glycine dipeptidase derivant

A technology of glycine dipeptide and fluorenylmethoxycarbonyl glycine dipeptide, which is applied in the direction of peptides, etc., can solve the problems that product separation is not suitable for large-scale production, product yield and purity are low, and achieve the effect of environmental friendliness and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

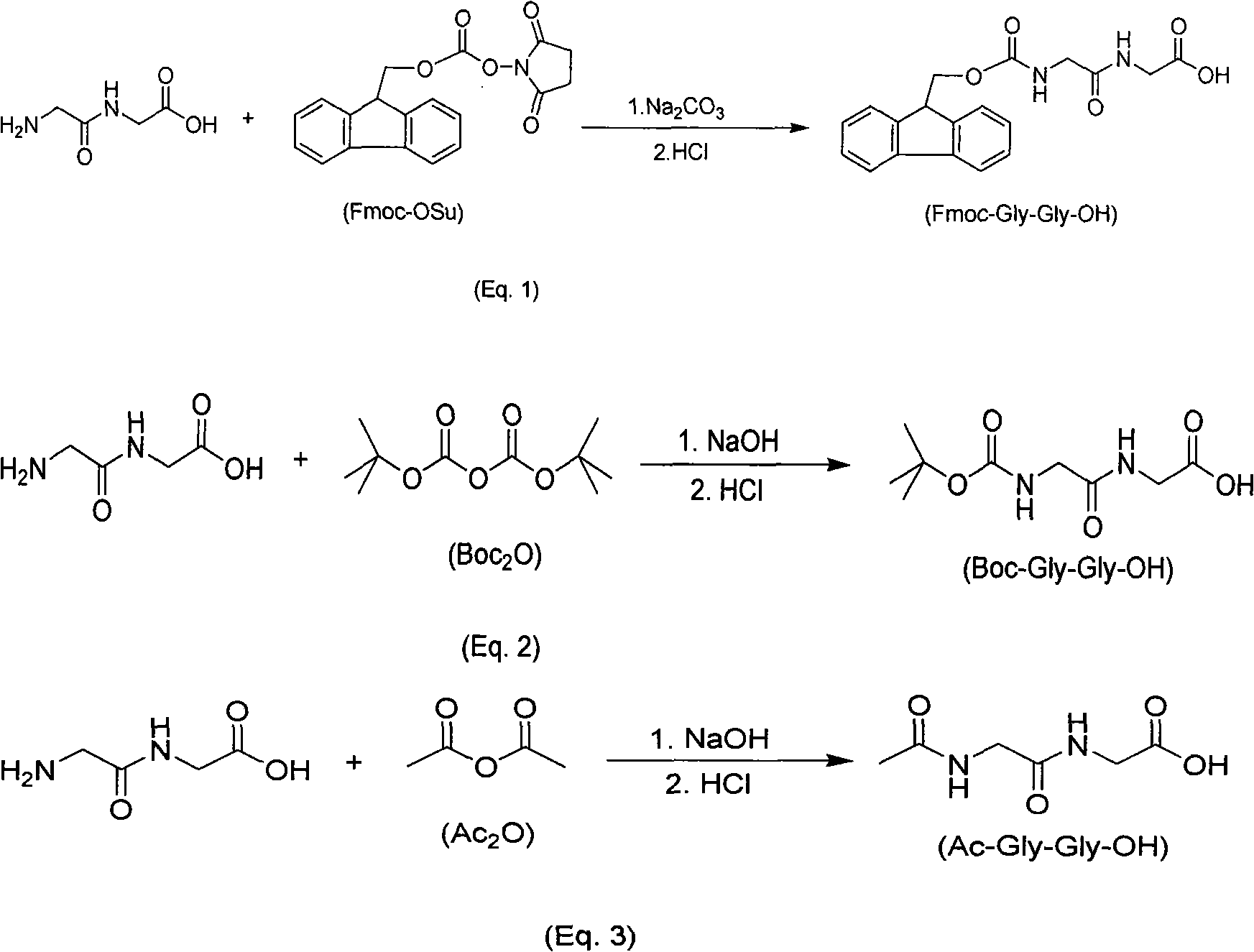

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 6.1 grams (0.050 moles) of glycine dipeptide in 63 mL of 10% sodium carbonate solution, stir to dissolve the glycine dipeptide, and add dropwise Fmoc-ONSu (16.8 grams, 0.05 mol) solution, the dropwise addition was completed in 30 minutes. After the dropwise addition, the reaction was stirred at 30° C. for 2 hours, diluted with about 50 mL of water, and the reaction solution was extracted with toluene (80 mL), and the resulting aqueous phase was acidified to pH = 2, and then extracted with ethyl acetate (100 mL), the obtained organic phase was washed with water, and the organic phase was concentrated to remove the ethyl acetate solvent, and a white solid was precipitated. After filtering and drying, 16.1 g of the product Fmoc-Gly-Gly-OH was obtained, with a yield of 91%.

Embodiment 2

[0027] Dissolve 6.1 grams (0.05 moles) of glycine dipeptide in 79 mL of 10% potassium carbonate solution, stir to dissolve the glycine dipeptide, and add dropwise Fmoc-ONSu (17.7 grams, 0.0525 mol) solution, the dropwise addition was completed in 30 minutes. After the dropwise addition, the reaction was stirred at 30° C. for 2 hours, diluted with about 50 mL of water, and the reaction solution was extracted with toluene (80 mL), and the resulting aqueous phase was acidified to pH = 2, and then extracted with ethyl acetate (100 mL), the obtained organic phase was washed with water, and the organic phase was concentrated to remove the ethyl acetate solvent, and a white solid was precipitated. After filtering and drying, 16.5 g of the product Fmoc-Gly-Gly-OH was obtained, with a yield of 93%.

Embodiment 3

[0029] Dissolve 6.1 g (0.050 moles) of glycine dipeptide in 63 mL of 10% sodium carbonate solution, stir to dissolve the glycine dipeptide, and add Boc dissolved in methanol (60 mL) dropwise at 20°C 2 O (10.9 g, 0.05 mol) solution, the dropwise addition was completed in 30 minutes. After the dropwise addition was completed, the reaction was stirred at 30° C. for 2 hours, and the reaction solution was extracted with methyl tert-butyl ether (80 mL). Acidify with hydrochloric acid to pH = 3, and then extract with ethyl acetate (100 mL). The obtained organic phase is washed with water, and then the organic phase is concentrated to remove the ethyl acetate solvent, and a white solid is precipitated. After filtering and drying, 9.29 g of the product Boc-Gly-Gly-OH was obtained, with a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com