High-efficiency electrochemical reactor

An electrochemical and reactor technology, which is applied in the field of electrochemical reactors, can solve problems such as uneven contact, affecting the adequacy of the reaction, and insufficiency, so as to reduce the concentration difference of the plate, strengthen the hydroxyl oxidation reaction, and improve the treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

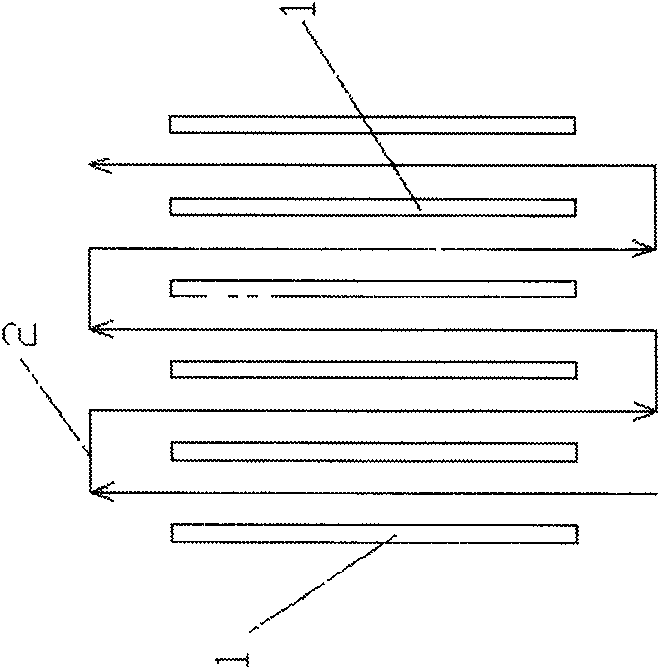

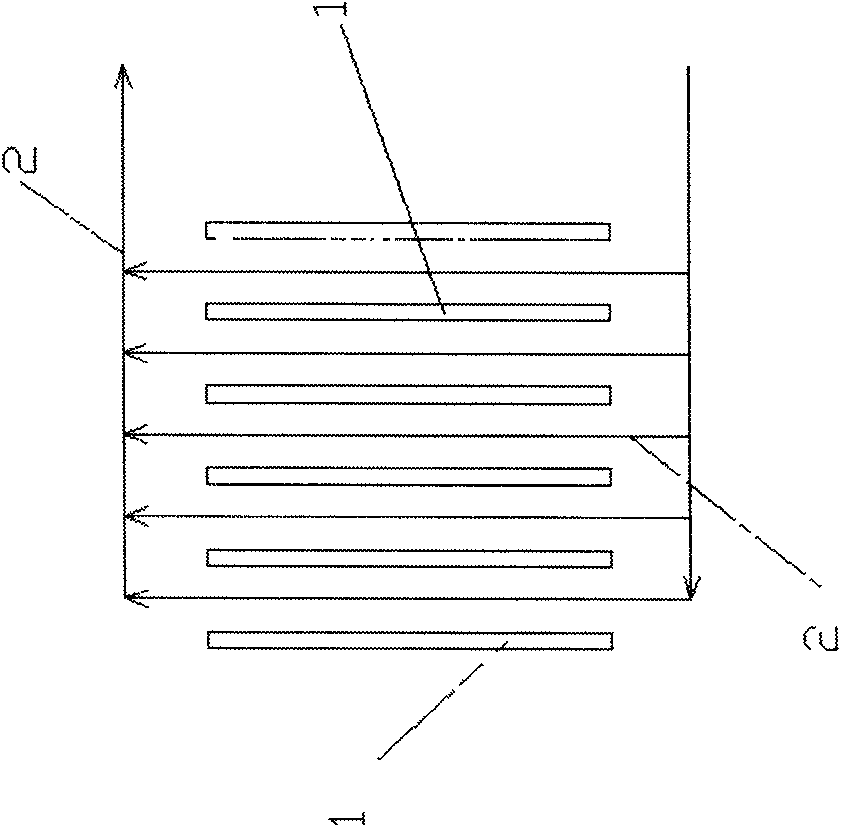

[0051] see figure 1 , figure 2 . 1 is the pole plate, and 2 is the water flow direction. In the two design methods, the water flow and the pole plate are in one-dimensional contact.

[0052] see Figure 3 to Figure 4 . This embodiment includes a tank body 11 with an upper cover plate 12 to seal the entire tank body, and the length, width and height are 500mm, 200mm, and 150mm respectively; the two sides of the tank body are respectively provided with a water inlet 13 and a water outlet 14, Several pole plates 15 are arranged in parallel in the tank body, and a water outlet 18 is arranged on the pole plate. The water outlet can be a through hole on the pole plate, or a gap at the edge of the pole plate; The device is made up of a rotating shaft 16, a driving wheel 17 and a blade 19. The blade 19 has a length of 120 mm, is fixed on the rotating shaft, and is arranged between every two adjacent pole plates. The driving wheel 17 drives the rotating shaft 16 to rotate at a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com