Lifting garbage compressor

A garbage compressor and lifting technology, which is applied in the direction of presses, garbage conveying, lifting devices, etc., can solve the problems of lowering the height of column buildings, short strokes of lifting cylinders, and complex structures, and achieve energy saving, short strokes, and stress small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment is described in detail below in conjunction with accompanying drawing:

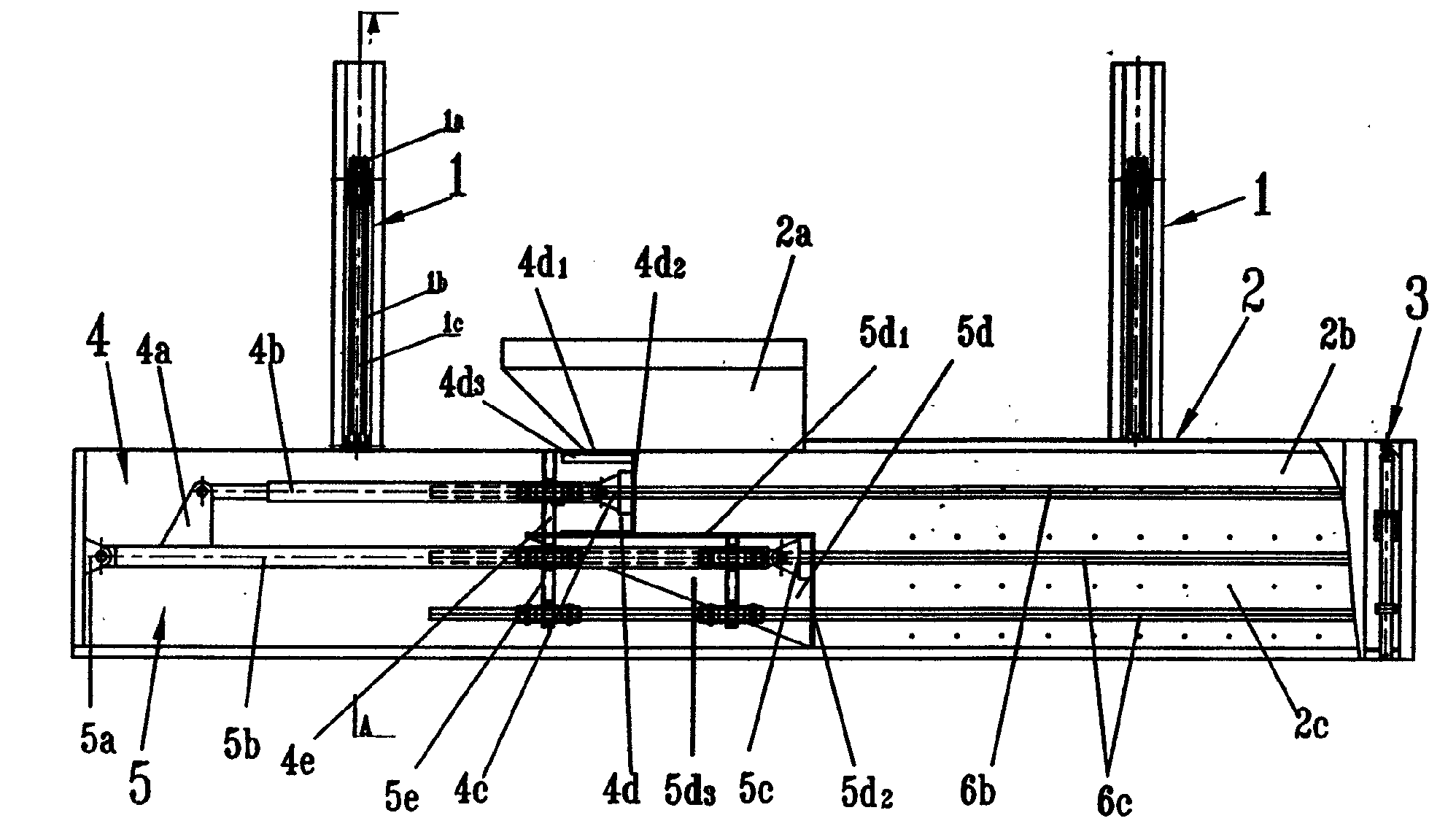

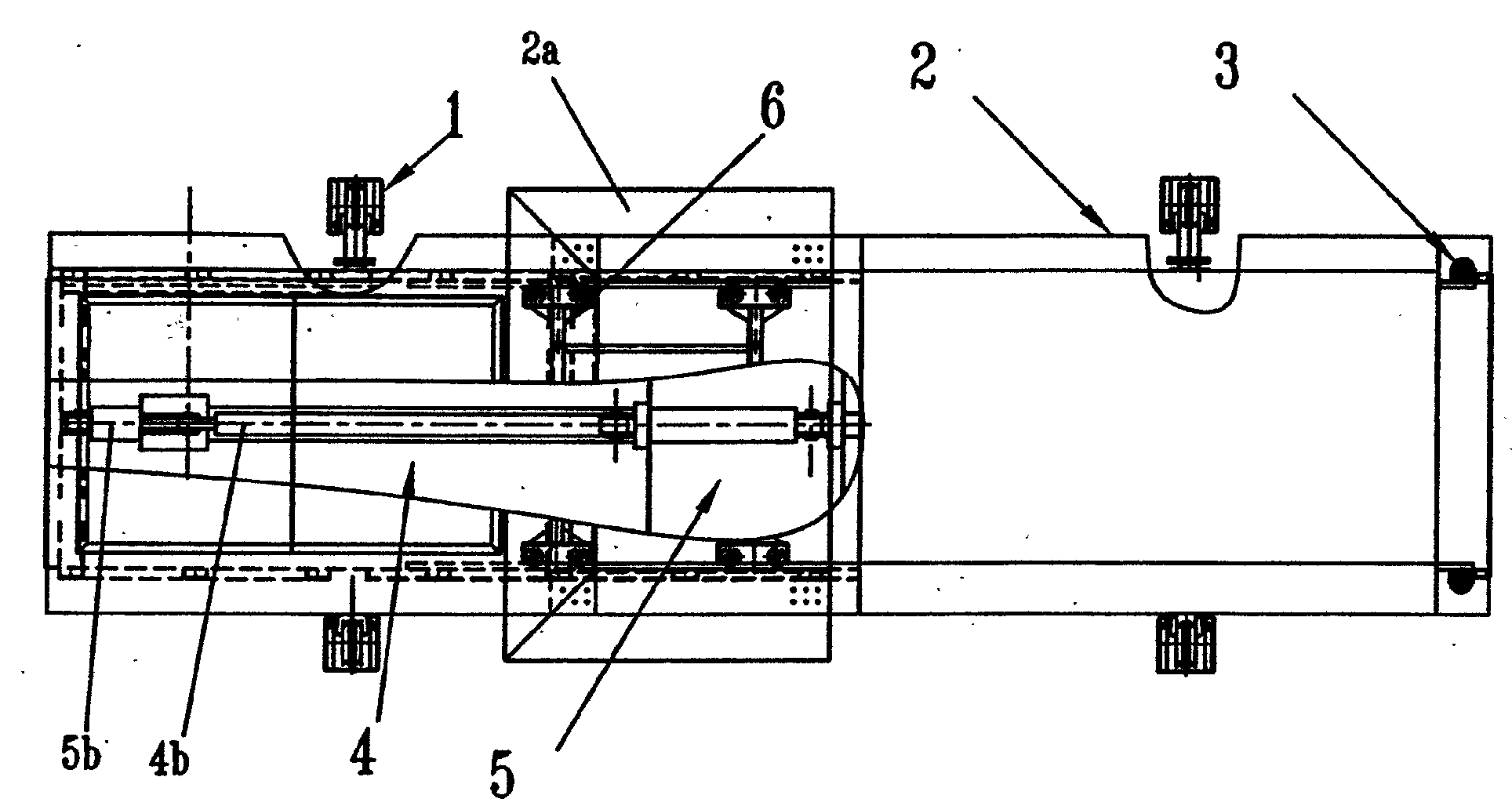

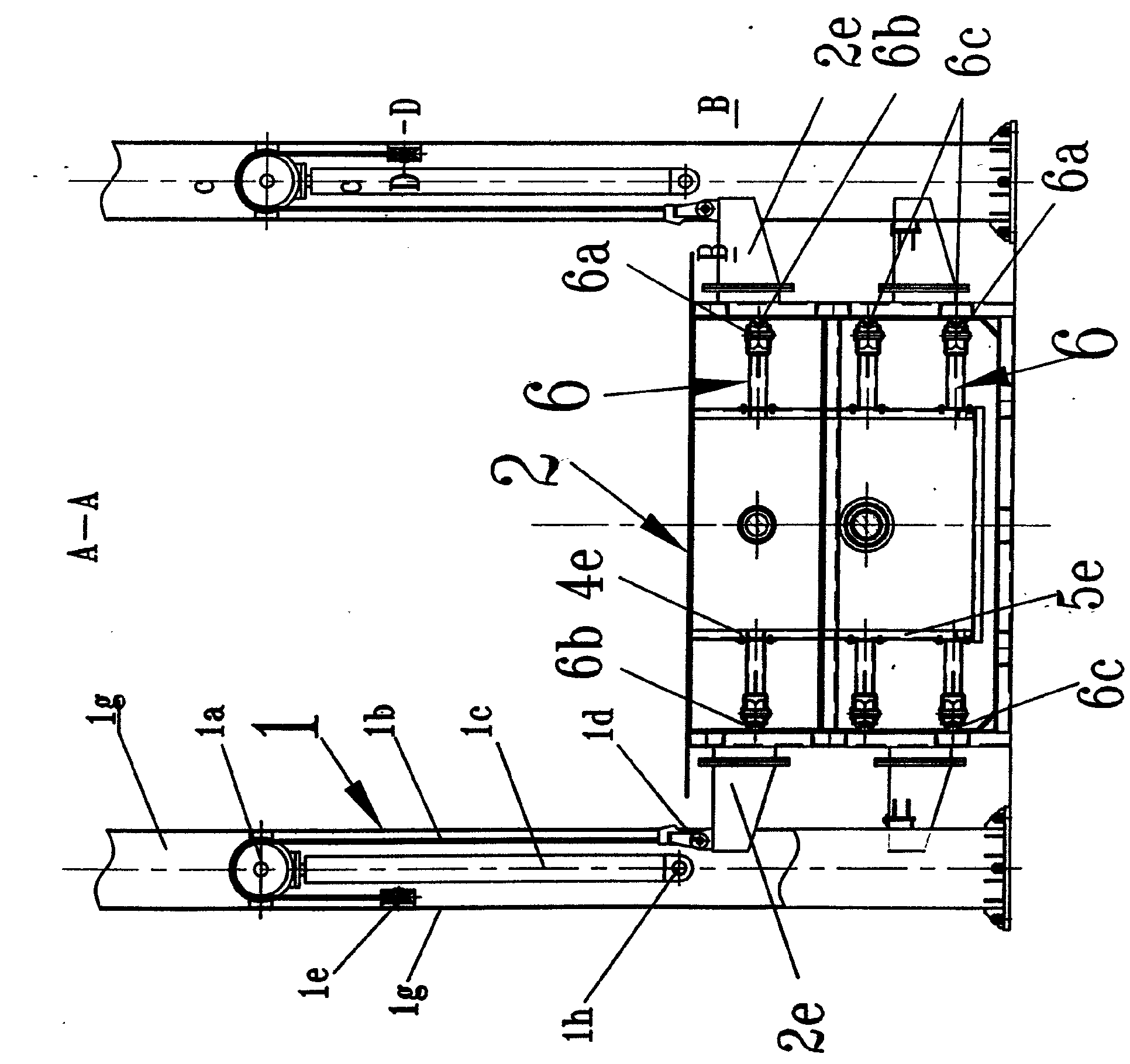

[0026] Lifting garbage compactor, (see figure 1 , figure 2 ) includes a lifting device 1, a garbage volume box 2 with a hopper 2a on the top and a gate mechanism 3 at the front end outlet, a garbage compression mechanism 4 and a push-out mechanism 5 placed in the garbage volume box, (see image 3 , Figure 4 , Figure 5 , Figure 6 ) The two sides of the box body of the garbage volume box 2 are fixed with cantilever beams 2e; the lifting device 1 is composed of a column 1g, an oil cylinder lifting mechanism, a pulley and sliding rope transmission mechanism; the column cross section is concave and hollow and is shaped on The opening is pressed and formed with a steel plate, and the cavity is respectively inserted into the oil cylinder lifting mechanism and the pulley and rope transmission mechanism from the opening; the oil cylinder lifting mechanism is composed of the oil cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com