Automatic loading and unloading device aiming at crankshaft

A technology of automatic loading and unloading, crankshaft, applied in metal processing and other directions, can solve the problems of high labor intensity and scratches on the surface of the crankshaft, and achieve the effect of improving work efficiency and saving time for loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

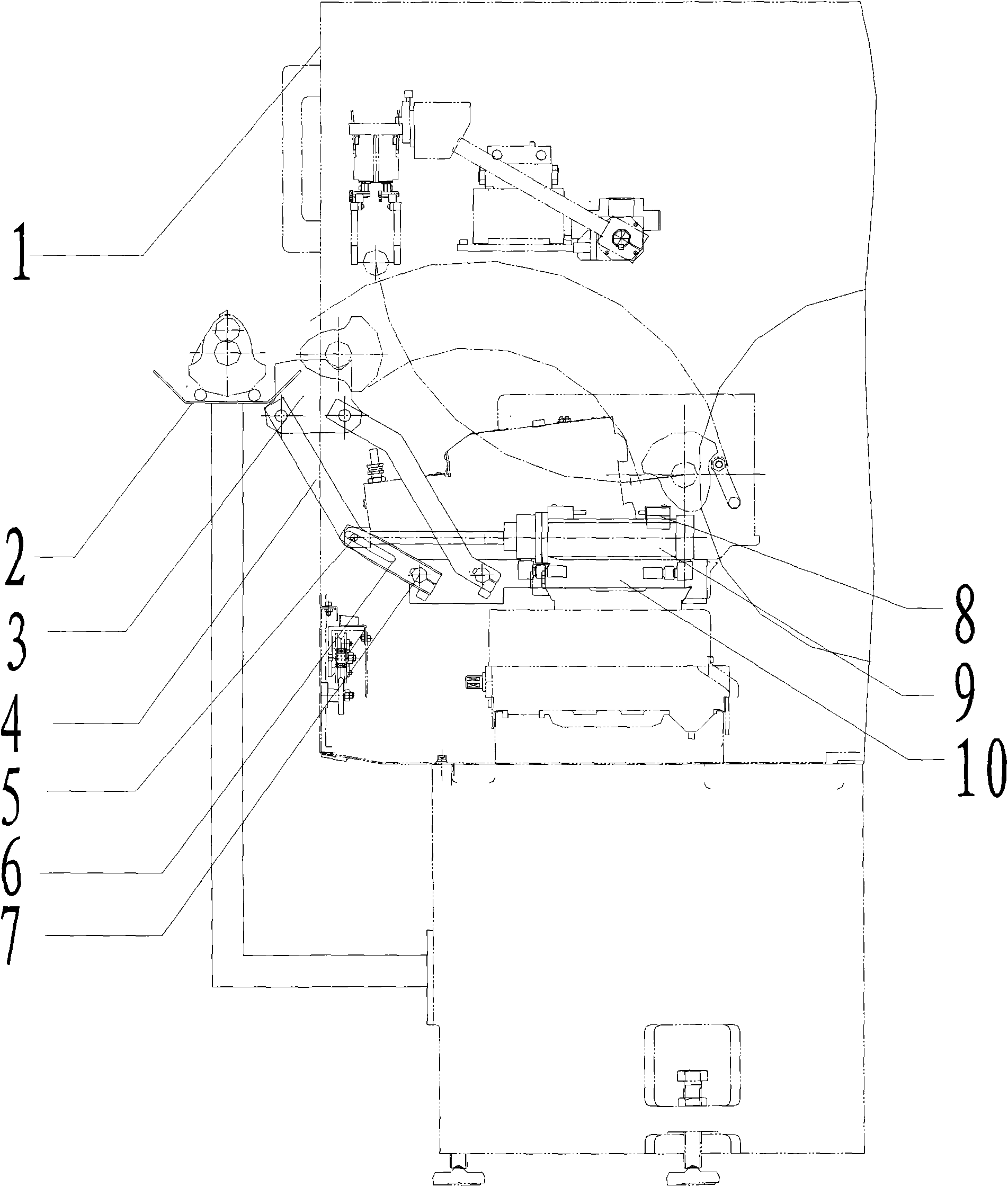

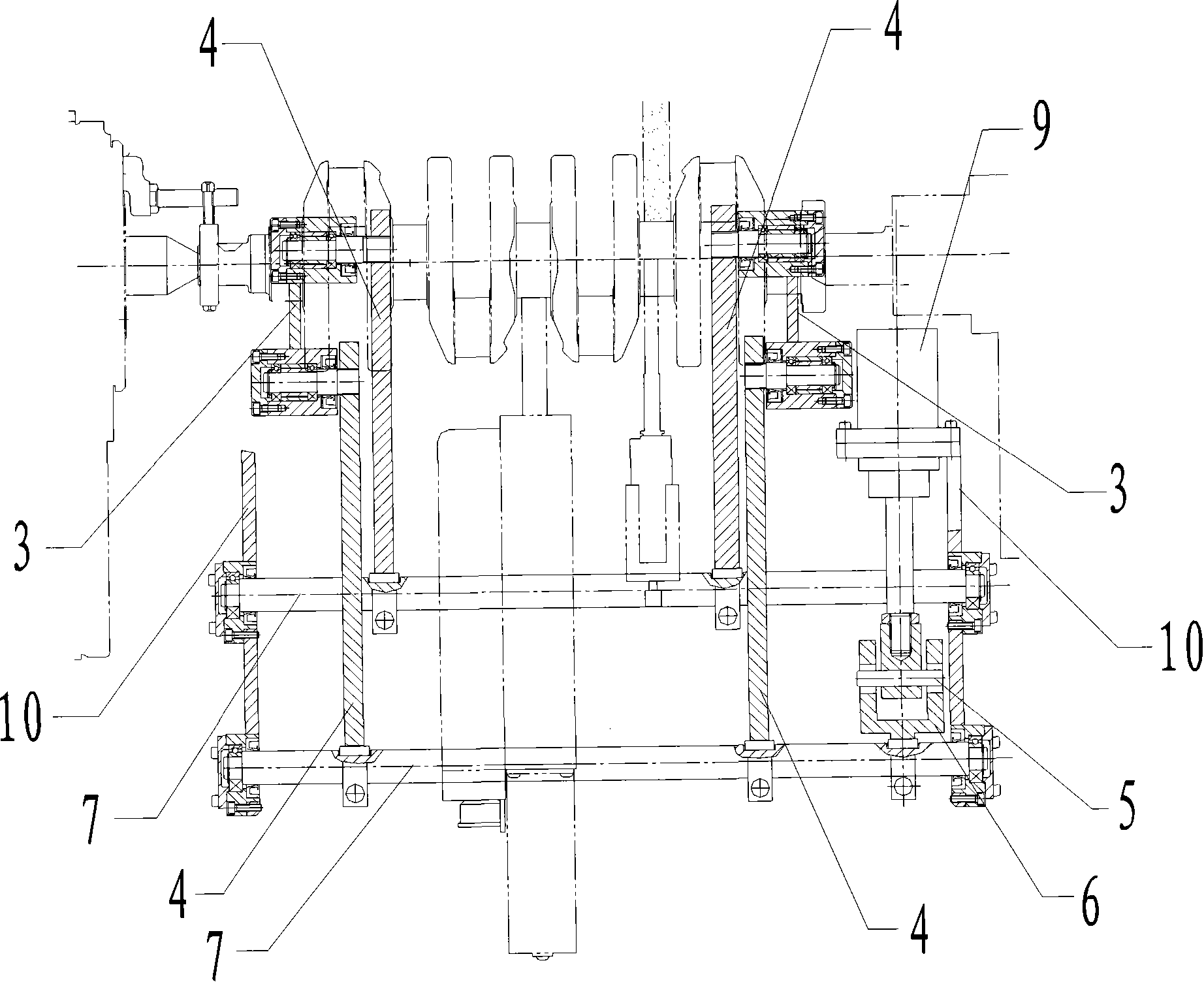

[0018] figure 1 with figure 2 It shows the application of the automatic loading and unloading device for the crankshaft provided by the present invention on the CNC grinding machine. The automatic loading and unloading device includes two left and right swing frames, and the swing frames are composed of two front and rear swing arms 4 and a workpiece bracket 3 The front and rear ends of the workpiece bracket are respectively hinged with the upper ends of the front and rear swing arms, so that when the swing arm drives the workpiece bracket to move, the workpiece bracket remains horizontal and does not make it The crankshaft transported on the top falls, and the lower ends of the front and rear swing arms are respectively connected to the front and rear shafts 7 through key couplings, so that when the shafts rotate, the swing arms can rotate accordingly, and the front and rear shafts pass through The bearing is connected with the frame 10 in rotation, and the frame for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com