Laser welding flexible jig suitable for trial manufacturing new car models or producing car bodies in white in limited quantities

A laser welding and flexible fixture technology, applied in the field of mechanical engineering, can solve the problems of unchanged installation position, decreased efficiency, and increased body manufacturing costs, and achieves the effect of avoiding fixture design and manufacturing, reducing production sites, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

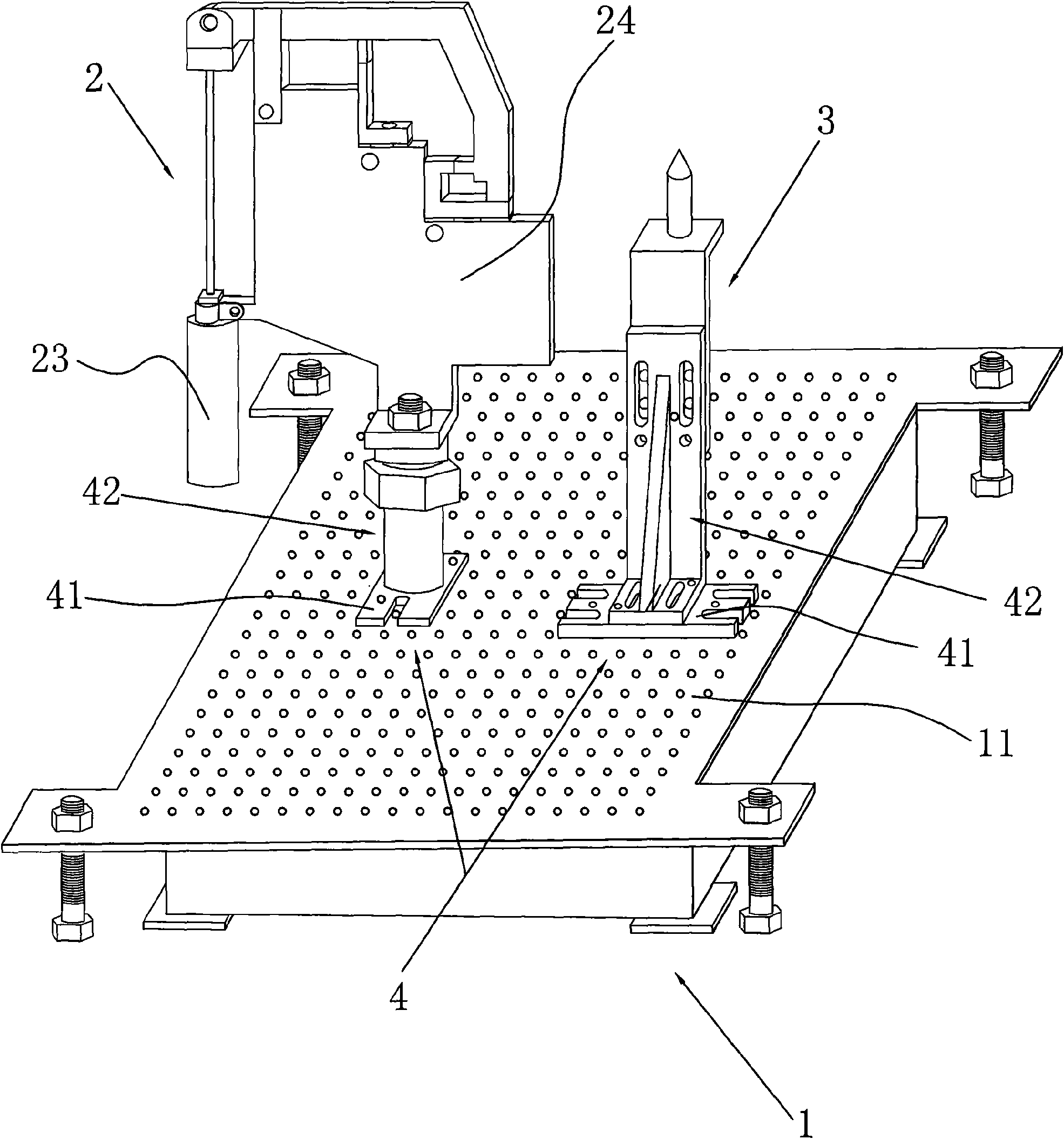

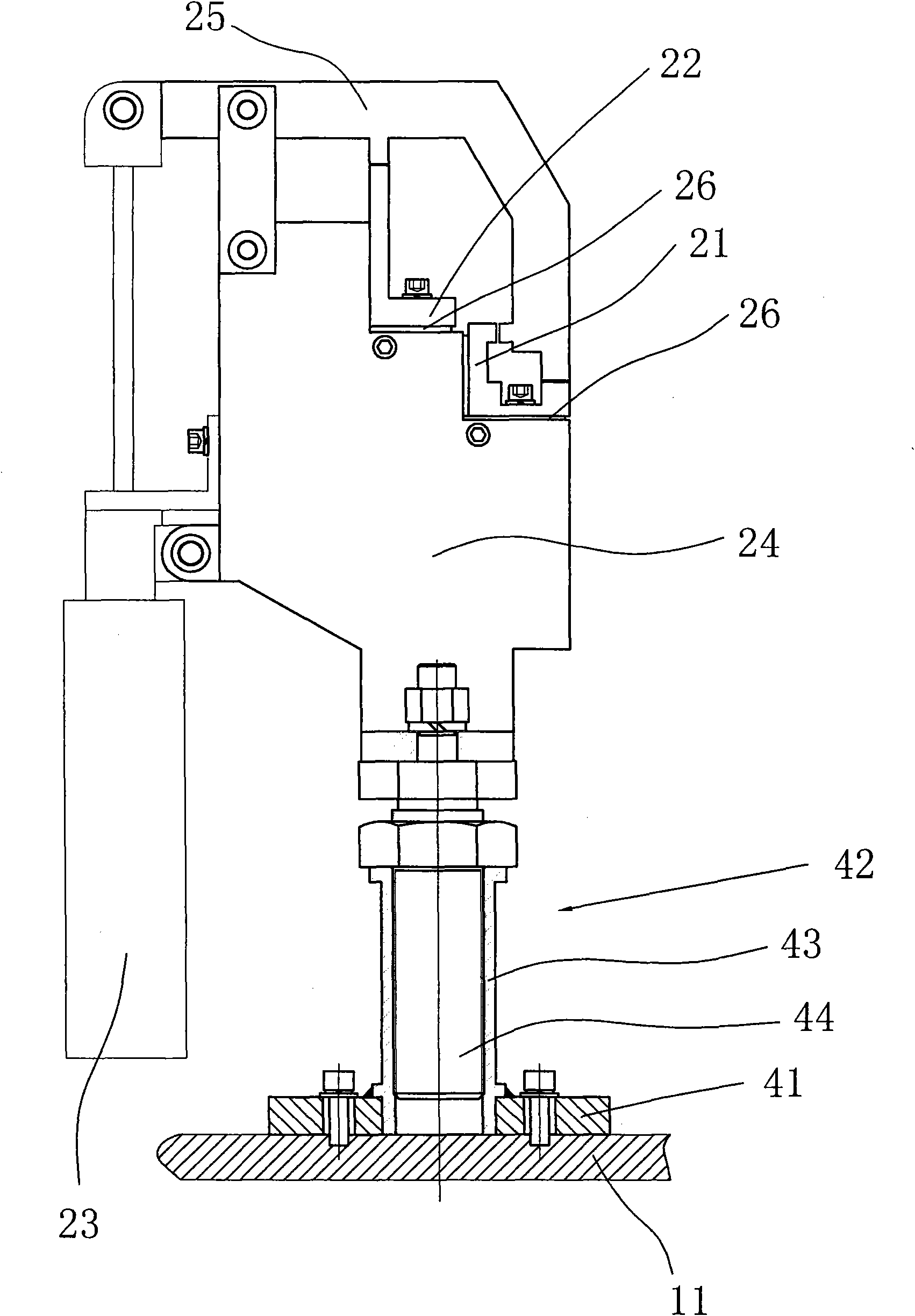

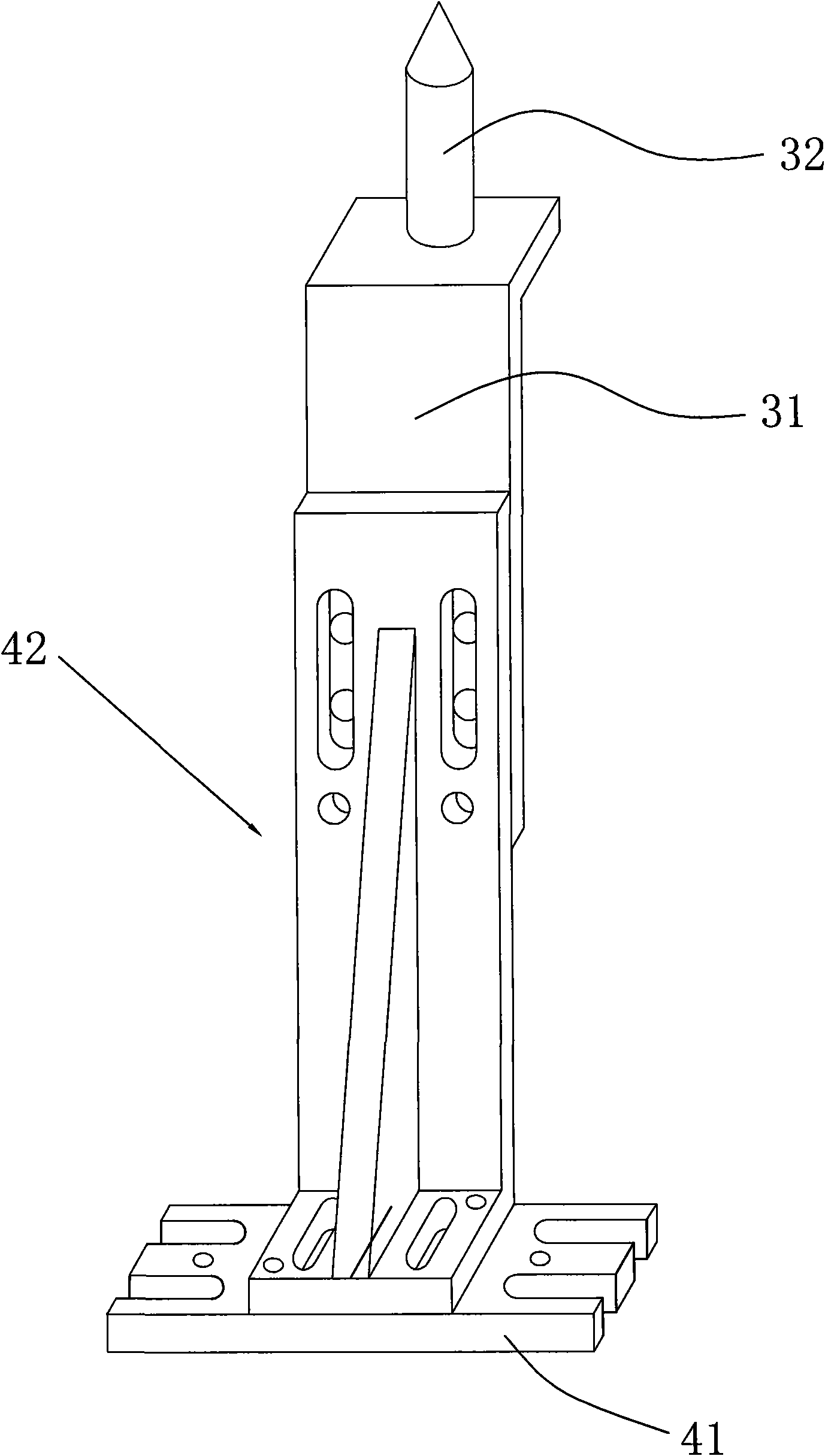

Embodiment 1

[0014] Wherein the horizontal adjustment member 41 is a flat plate with an elongated hole or an elongated groove, and the shape and structure of the vertical adjustment member 42 can be different, such as Figure 1-Figure 3 The horizontal adjuster 41 used under the shown clamping mechanism and the horizontal adjuster 41 used under the positioning mechanism are all flat plates with U-shaped grooves, but their vertical adjusters 42 are different. The vertical adjuster 42 used under the clamping mechanism Straight adjusting part 42 is mainly made up of an internal thread sleeve 43 and a screw rod 44, and internal thread sleeve 43 is fixedly connected on the horizontal adjusting part 41, and one end of screw rod 44 is connected with clamping mechanism 2, and the other end is connected with internal thread sleeve 43 ( See figure 1 and figure 2 ), the adjustment accuracy of this vertical adjustment member is high, but the adjustment speed is relatively slow. The vertical adjuster...

Embodiment 2

[0017] The clamping mechanism and positioning mechanism of the present invention can be required by different stations, and their shapes may be different, such as Figure 4 The illustration exemplifies another kind of clamping mechanism, which is a clamping mechanism required by another step in the welding process of the car body, although the shape is the same as figure 2 The clamping mechanism shown has a different shape, but can still be used figure 2 or image 3 Adjustment seat shown.

[0018] When the present invention is in use, take welding a car door as an example. When welding a car door of a certain model, the clamping mechanism 2, positioning mechanism 3 and adjustment seat 4 required by each station can be installed on the base 1, and these clamping The mechanism clamps the car door, and the positioning mechanism positions the car door. The position of the clamping mechanism in the two directions vertical to the horizontal plane can be adjusted by adjusting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com