Method and device for spreading conducting wire in micro-tension overhead suspension way

A micro-tension and wire technology, applied in overhead installation, overhead line/cable equipment, cable installation, etc., can solve the problems of high construction cost, economic loss of power supply enterprises, power consumption enterprises, environmental damage, etc., and improve construction efficiency , reduce construction costs, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

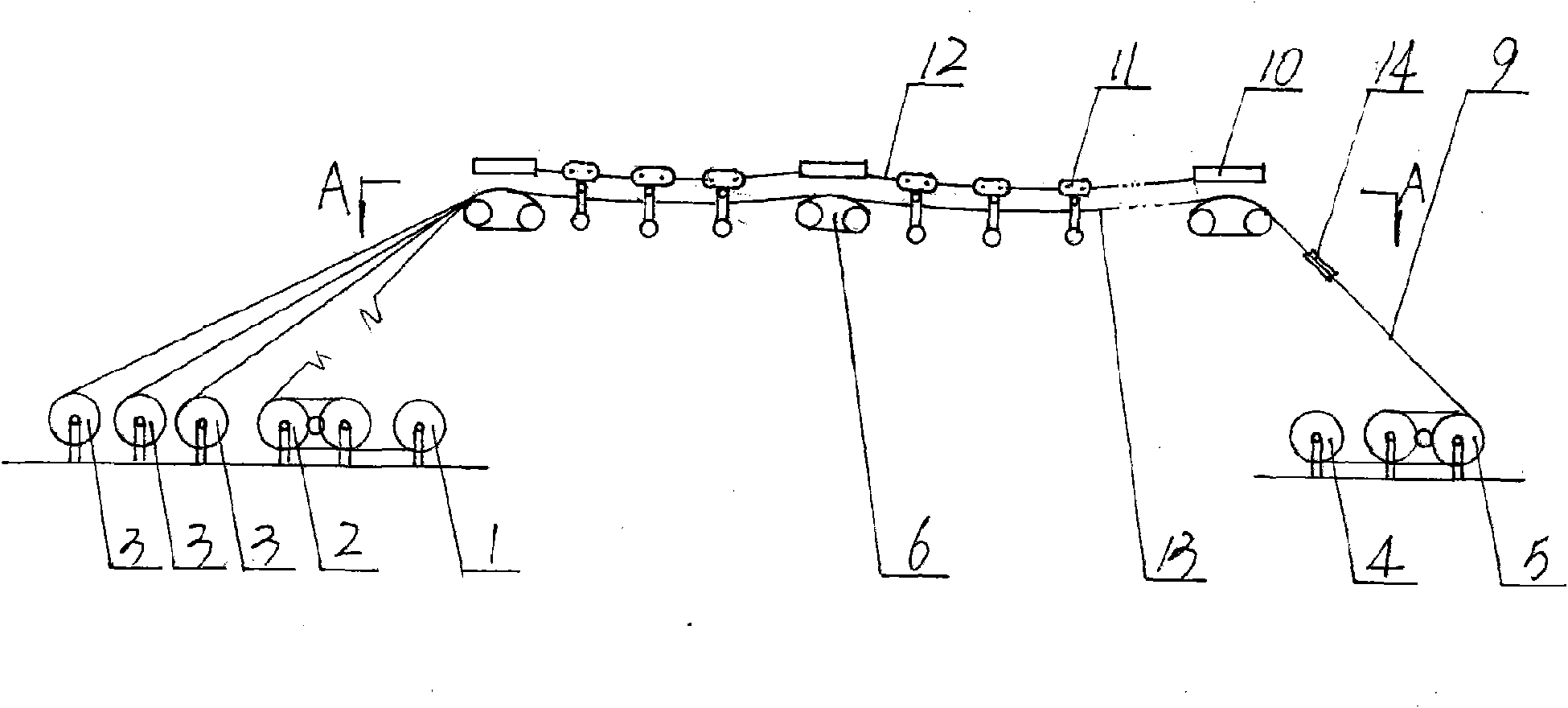

[0034] Such as Figure 1~5 Shown: the method provided by the present invention comprises launching guide rope, traction rope and lead wire, and specific method is as follows:

[0035] 1) Set a pay-off reel 1, a tension machine 2 and a wire reel 3 at the beginning of the line, and set a recovery reel 4 and a tractor 5 at the end of the line;

[0036] 2) Temporarily fix the electric conveyor 6 on the cross arm 10 of each base tower of the line;

[0037] 3) Utilize the aircraft to deploy the guide ropes 7 one by one in the wire grooves of the electric conveyors 6 from the beginning to the end of the line, and then wind the rope ends of the guide ropes 7 on the recovery disc 4 through the tractor 5;

[0038] 4) Take out the traction rope 9 from the pay-off reel 1, pass the tension machine 2 and connect the guide rope 7 through the connector 8, start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com