Micro-pressure high-temperature boiler

A high-temperature, boiler technology, applied in steam boilers, steam superheating, steam generation, etc., can solve the problems of less heat energy and low steam outlet temperature, achieve high heat utilization efficiency, low operating costs, and reduce smoke and dust pollution loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

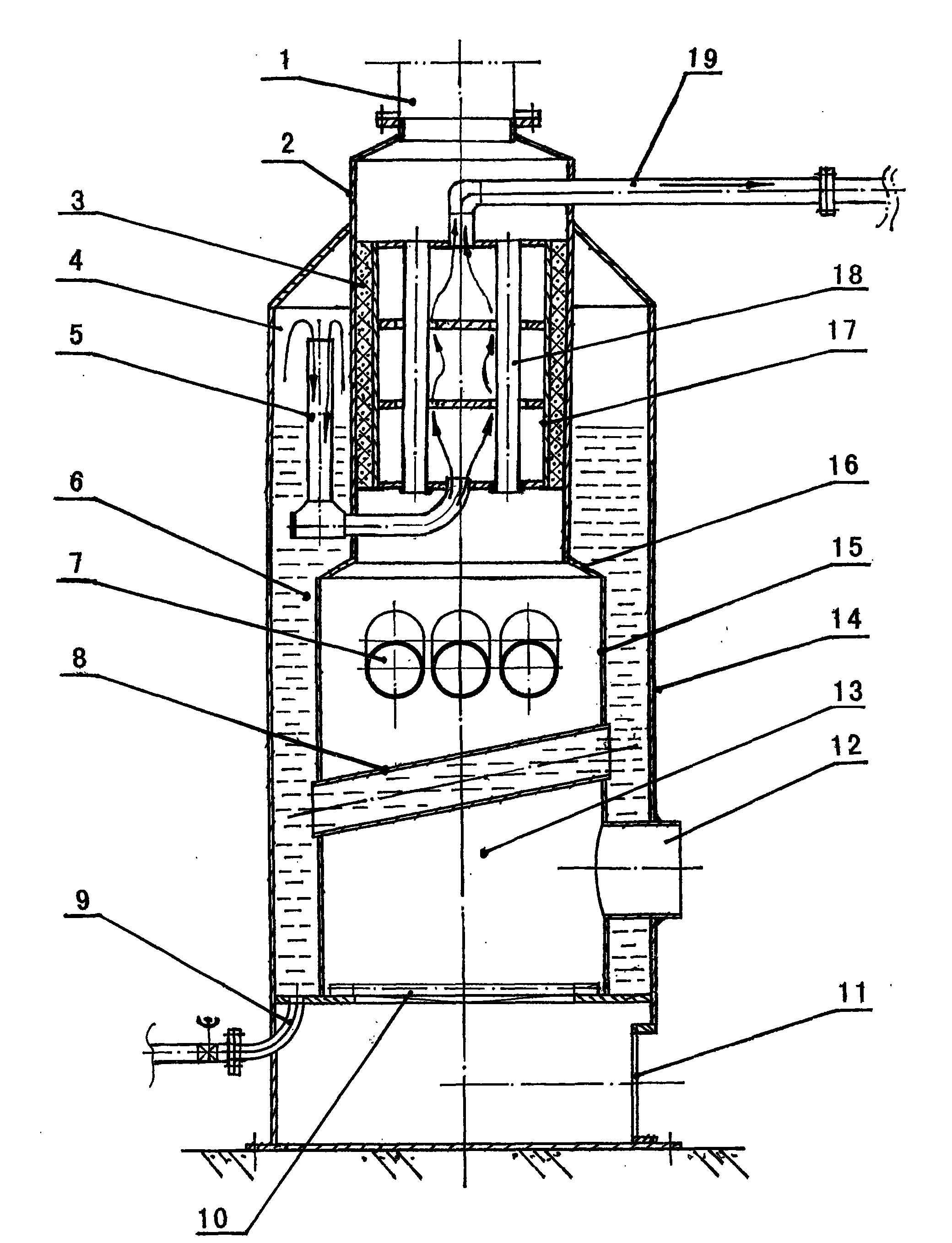

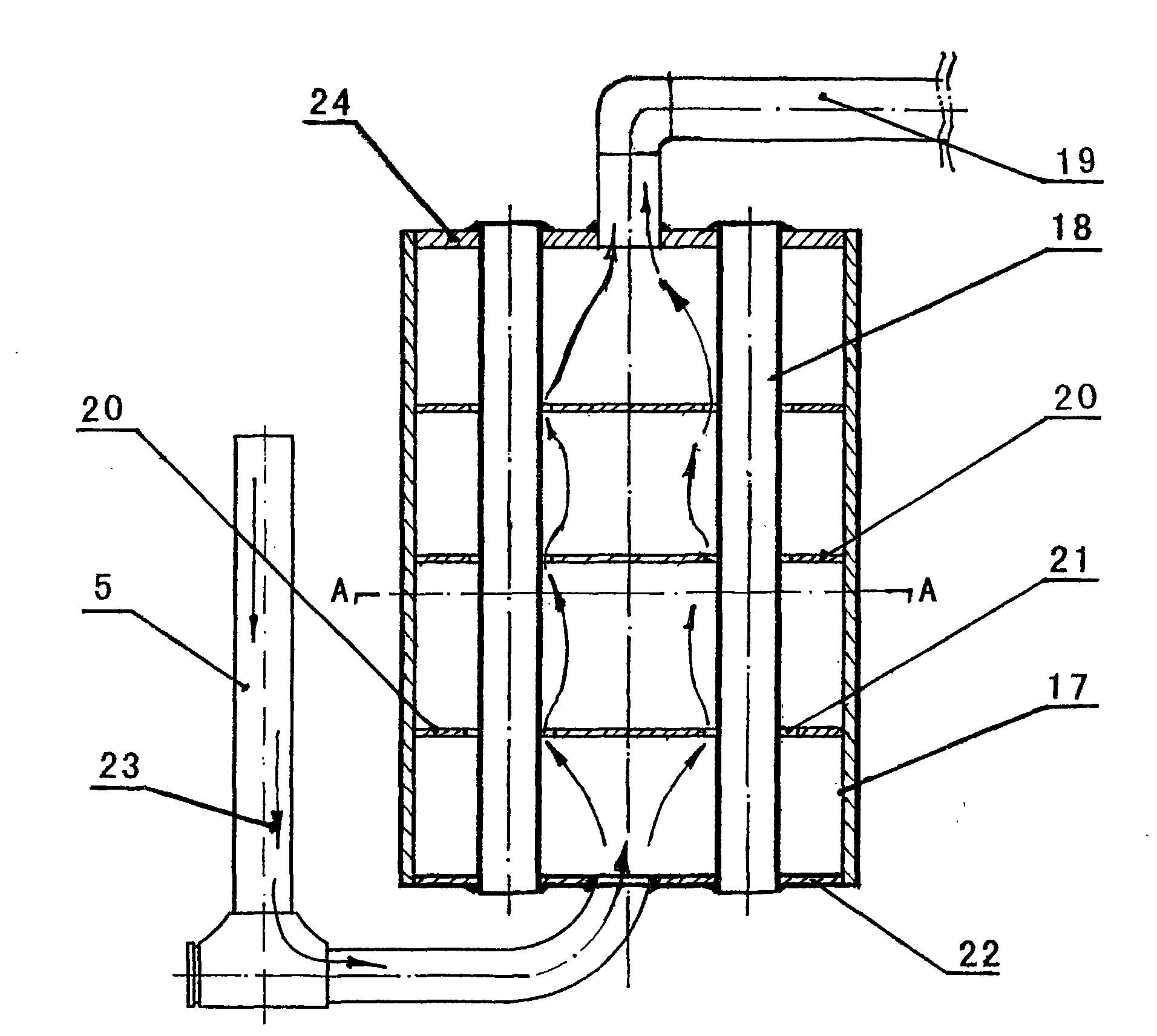

[0018] Describe the embodiment of the micro-pressure high-temperature boiler that the present invention proposes below in conjunction with accompanying drawing:

[0019]A micro-pressure high-temperature boiler, which is mainly composed of a pot shell 14, a furnace 15, a water inlet pipe 9, a chimney 2, a furnace door ring 12, a set of horizontal water pipes 7, 8 and a built-in superheater 17, in the furnace 15 The top end is fixedly connected to the chimney 2 by the head 16 and forms a closed water tank 6 with the pot shell 14. The chimney 1 is installed on the connecting pipe seat at the top of the chimney 2, and the furnace door ring 12 passes through the water tank 6 and is connected to the furnace gall 15 and the pot shell. The body 14 communicates with the furnace 13 formed by the furnace 15, and a group of horizontal water pipes 7, 8 are installed in the furnace 13 in a criss-cross and oblique arrangement, and a fire grate 10 and a slag hole 11 are arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com