Technology for constructing anti-collision bridge pier by steel cofferdam

A steel cofferdam and anti-collision technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of low construction efficiency, complicated construction process, and occupation of the main construction period, achieve good energy absorption effect, simplify the construction process, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

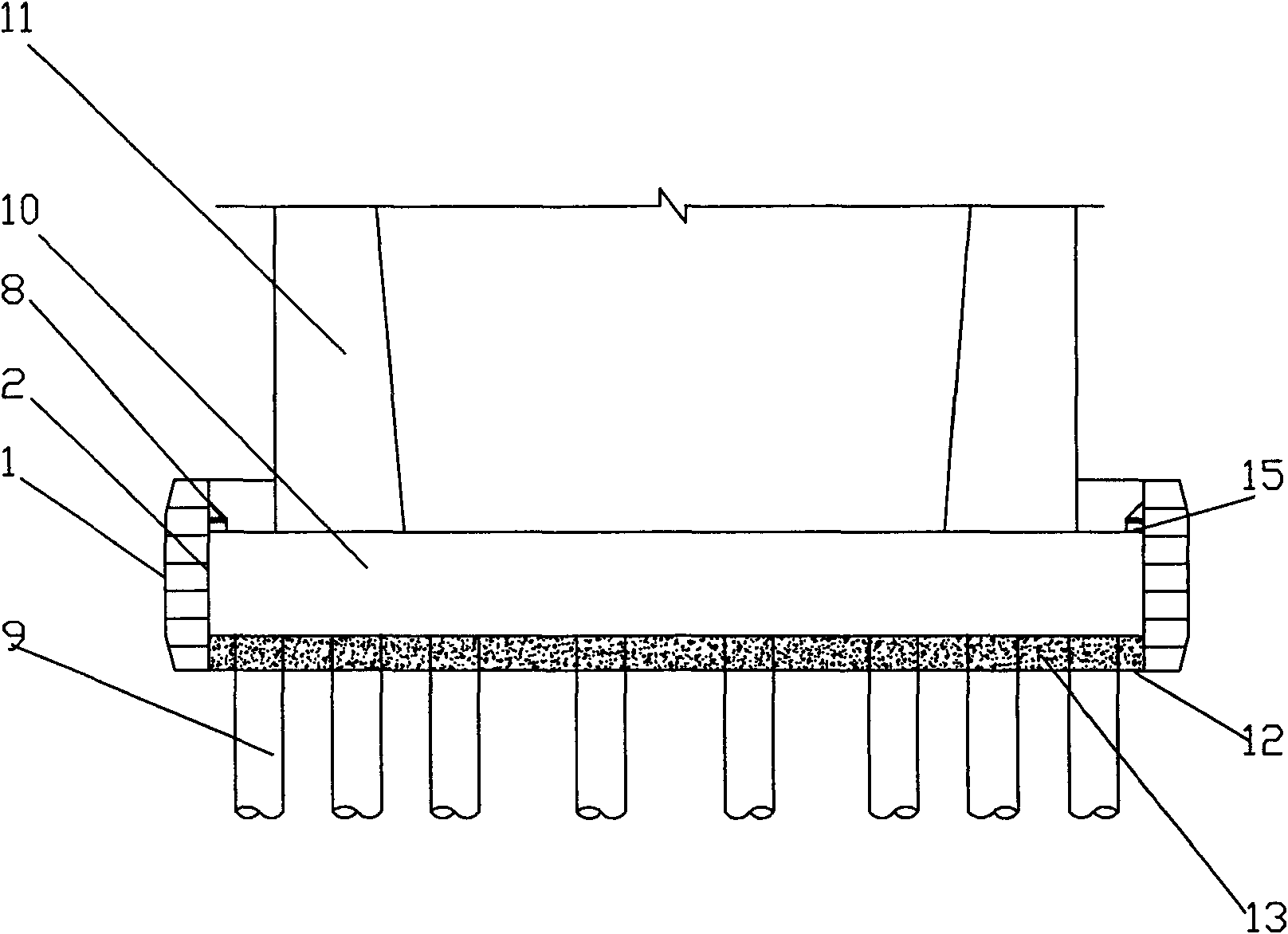

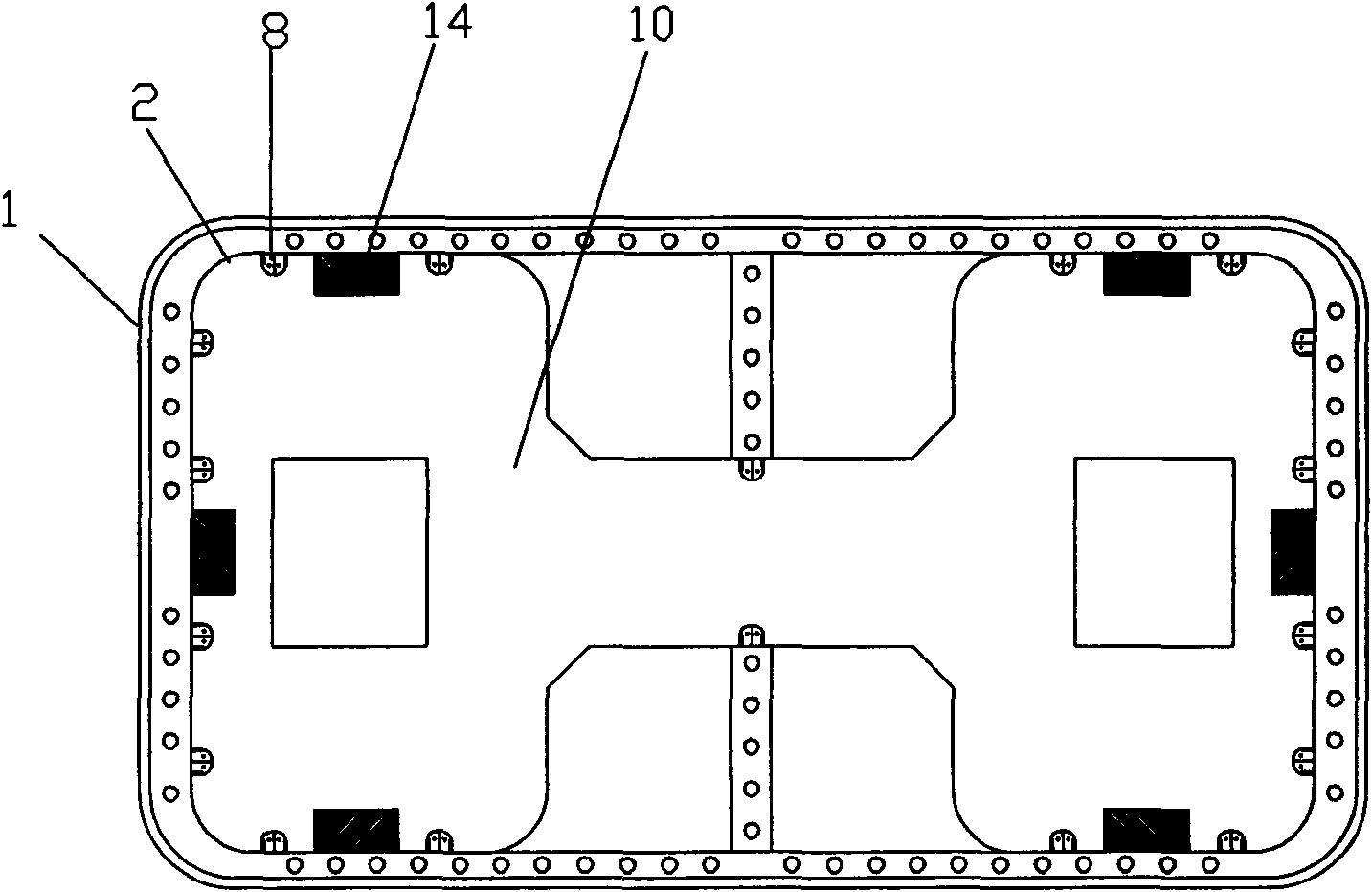

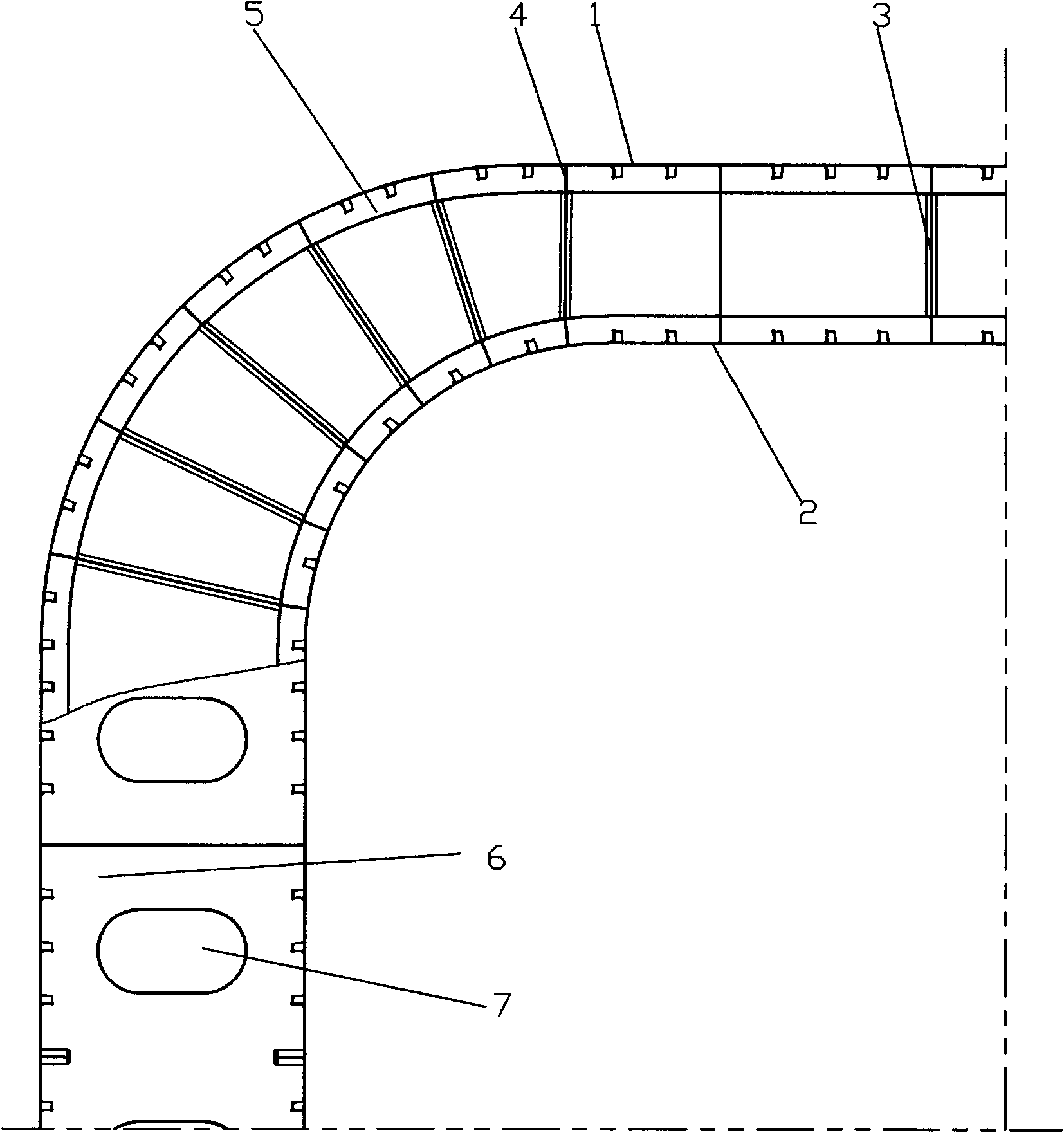

[0024] figure 1 It is a schematic diagram of the structure of the present invention after installation, figure 2 for figure 1 Top view of image 3 Is a schematic diagram of the transverse cross-sectional structure of the present invention, Figure 4 It is a schematic diagram of the longitudinal cross-sectional structure of the present invention, as shown in the figure: the process of constructing an anti-collision bridge pier by using a steel cofferdam in this embodiment includes the following steps:

[0025] a. Piles are driven underwater, and the bottom plate 12 is fixed horizontally on top of the pile 9;

[0026] b. Stand the prefabricated anti-collision steel cofferdam on the bottom plate so that the top of the anti-collision steel cofferdam is higher than the water surface; the anti-collision steel cofferdam includes an inner layer 2 and an outer layer 1, and the inner layer 2 and The outer layer 1 is respectively enclosed and fixedly connected by connectors to form a sandwic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com