Water transparent heat insulation paint and preparation method thereof

A heat-insulating coating and transparent technology, applied in the direction of coating, can solve the problems of inability to effectively block the entry of solar radiation energy, restricting large-scale application and promotion, and affecting the demand for lighting, which is conducive to large-scale promotion. and application, easy to promote and apply on a large scale, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

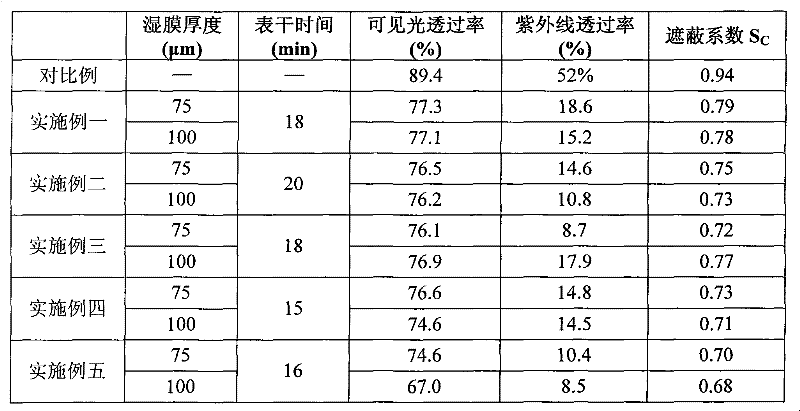

[0024] The embodiment of the present invention relates to a water-based transparent heat-insulating paint, which is composed of 50-80% water-based acrylic resin, 10-48% nano slurry, 1-10% solvent and 1-3% additives by weight percentage.

[0025] The water-based acrylic resin adopts one-component room temperature curing polyurethane modified water-based acrylic resin, and its solid content is 35%.

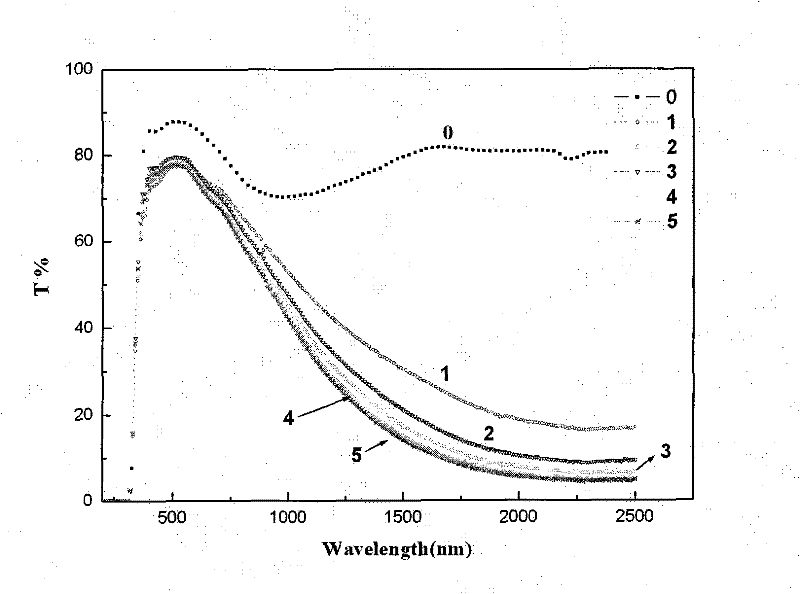

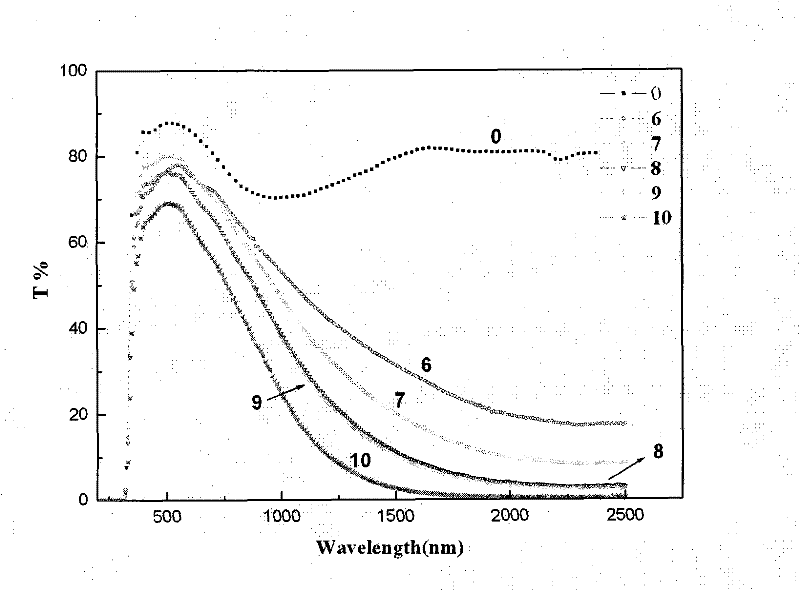

[0026] The nano slurry is one of silicon dioxide / tin oxide nano composite powder or tin antimony oxide nano dispersion or their combination, and the solid content of the nano slurry is 20%. When the combination of the two is used, the mass ratio is silicon dioxide / tin oxide nanocomposite powder: tin antimony oxide nano dispersion = 1:2-3, wherein the particle diameter of the tin antimony oxide nano dispersion is 50-100nm.

[0027] Silica / tin oxide nanocomposite powder is a silica / tin oxide nanocomposite particle with a core-shell structure, which uses nano-silicon dioxide as the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com