Method for combined preparation of pineapple polyphenol and juice by taking pineapple peel as main material and application thereof

A technology of pineapple peel and pineapple peel dregs, applied in the fields of application, plant raw materials, food preparation, etc., can solve the problems of pineapple peel waste, etc., achieve significant economic benefits, reduce production costs, and reduce the degree of browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

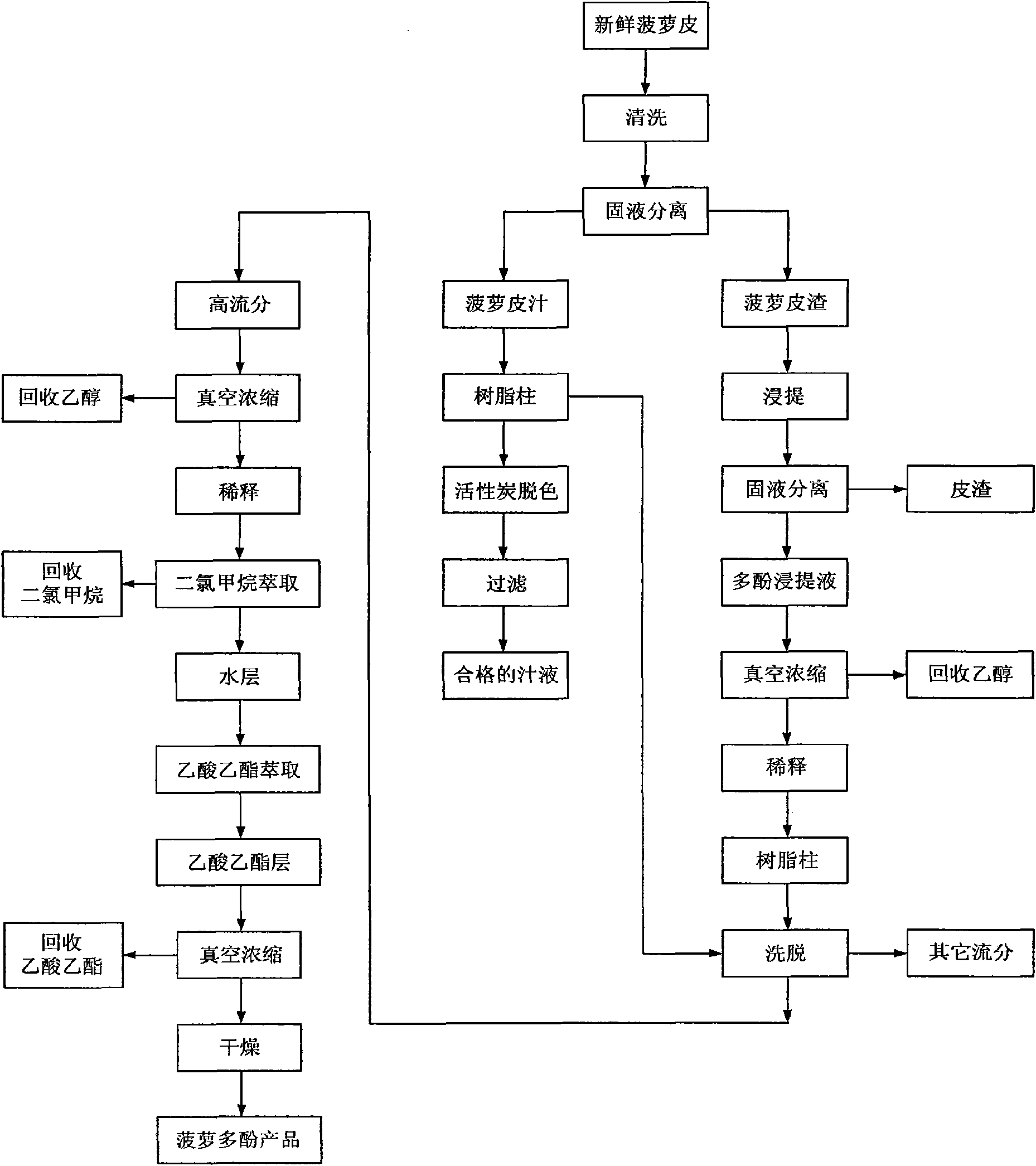

Image

Examples

Embodiment 1

[0035] (1) Weigh 200kg of fresh pineapple peel, wash, squeeze and centrifuge to obtain 140.6L pineapple peel juice and 55.6kg pineapple peel residue.

[0036](2) Flow the pineapple peel juice into the XDA-5 resin column at a flow rate of 1.0BV / h to adsorb polyphenols and pigments until the resin column reaches adsorption saturation, and collect the effluent before the resin column absorbs the leakage point. The effluent after the leakage point of the resin column adsorption and the residual liquid in the resin column need to be collected separately, and reloaded on the column for adsorption treatment until all the pineapple peel juice flows out and is collected before the leakage point of the resin column. Then, 250g of powdered activated carbon is added in the collected liquid (the consumption of activated carbon is 1.78g / L), stirring and decolorizing for 30min, and obtaining clarified fruit juice through filtration, the sugar content of fruit juice and the loss of vitamin C a...

Embodiment 2

[0042] (1) Weigh 150kg of fresh pineapple peel, wash, squeeze and centrifuge to obtain 100.2L of pineapple peel juice and 45.4kg of pineapple peel residue.

[0043] (2) Flow the pineapple peel juice into the AB-8 resin column at a flow rate of 1.5BV / h to adsorb polyphenols and pigments until the resin column reaches adsorption saturation, and collect the effluent before the resin column absorbs the leakage point. The effluent after the leakage point of the resin column adsorption and the residual liquid in the resin column need to be collected separately, and reloaded on the column for adsorption treatment until all the pineapple peel juice flows out and is collected before the leakage point of the resin column. Then, 280g of powdered activated carbon is added in the collected liquid (the consumption of activated carbon is 2.80g / L), stirring and decolorizing for 45min, and obtaining clarified fruit juice through filtration, the sugar content of fruit juice and the loss of vitam...

Embodiment 3

[0049] (1) Weigh 150kg of fresh pineapple peel, wash, squeeze and centrifuge to obtain 100.5L pineapple peel juice and 44.8kg pineapple peel residue.

[0050] (2) Flow the pineapple peel juice into the X-5 resin column at a flow rate of 2.0BV / h to adsorb polyphenols and pigments until the resin column reaches adsorption saturation, and collect the effluent before the resin column absorbs the leakage point. The effluent after the leakage point of the resin column adsorption and the residual liquid in the resin column need to be collected separately, and reloaded on the column for adsorption treatment until all the pineapple peel juice flows out and is collected before the leakage point of the resin column. Then, 400g of powdered activated carbon is added in the collected liquid (the consumption of activated carbon is 3.98g / L), stirred and decolorized for 30min, and can obtain clarified fruit juice through filtration, the sugar content of fruit juice and the loss of vitamin C are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com