Fountain aeration spray head and manufacture method and use method thereof

A nozzle and aeration technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of large floor area, small air supply, complex equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

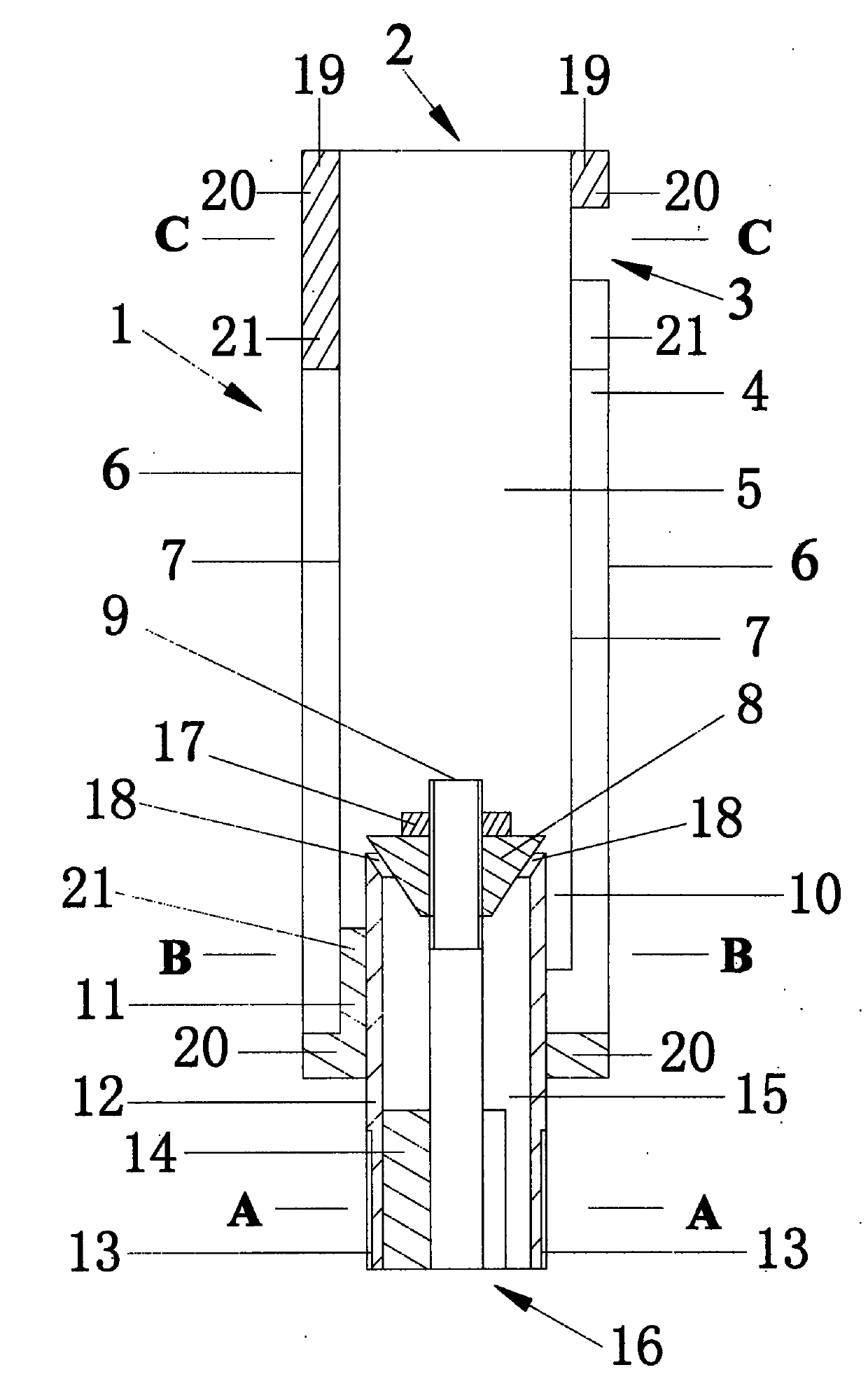

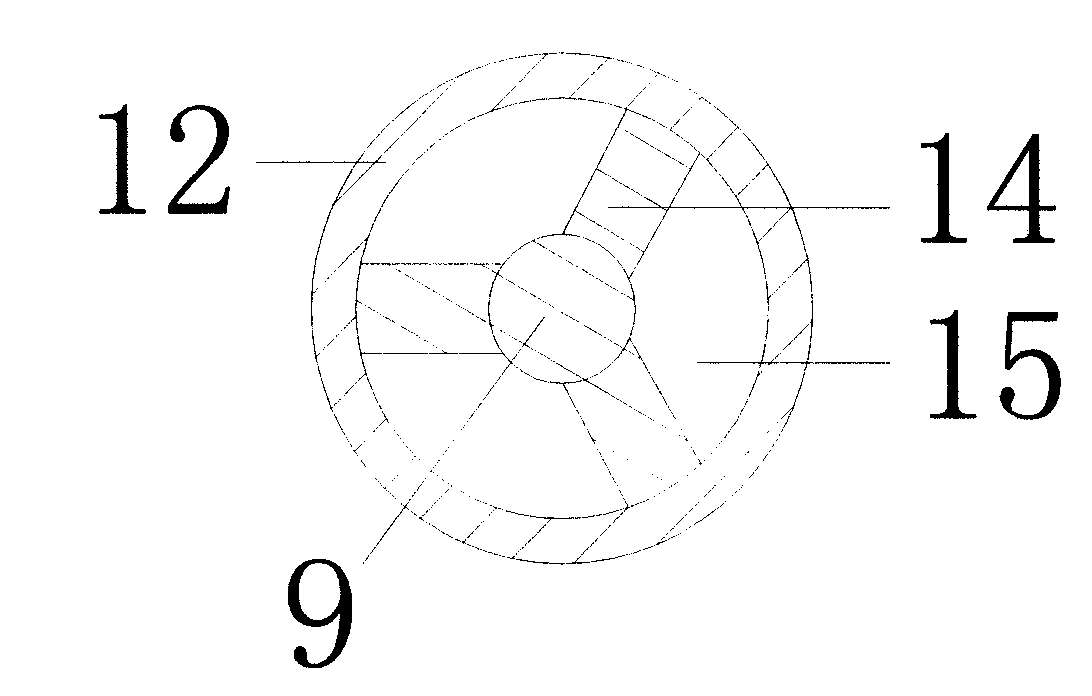

Embodiment 1

[0074] The nozzle body (1) is composed of the nozzle outer barrel (6), the nozzle inner barrel (7), the air-water mixing diversion cavity (5), the water source nozzle (12) and the flow regulator (9), passing through the cone diversion bracket (14). The lower flange bracket (11) and the upper flange bracket (19) are connected to form the sprinkler body (1). The water source nozzle (12) is in the shape of a hollow cylinder as a whole, and the central part is provided with a flow regulator (9), and the water source At least 3 cone-shaped deflector supports (14) are equidistantly arranged at the lower end of the nozzle (12). The two sides of the cone-shaped deflector support (14) are respectively connected to the inner wall of the water source nozzle (12) and the flow regulator (9) The outer walls are fixedly connected, and the conical deflector bracket (14) fixes the flow regulator (9) in the middle of the water source nozzle (12).

[0075] The cone-shaped deflector bracket (14) sep...

Embodiment 2

[0080] The outer wall of the water source nozzle (12) is fixedly provided with a lower flange bracket (11) around the outer wall. The lower part of the lower flange bracket (11) is an annular closing plate (20) in the shape of an eye ring, along the inner side of the annular closing plate (20) At least three flange plates (21) are arranged at equal intervals. The flange plates (21) protrude on the annular closing plate (20). The outer side of the annular closing plate (20) forms a protruding platform. The concave gap forms an air outlet (10), and the inner side of the lower end flange bracket (11) is fixedly connected with the outer wall of the water source nozzle (12).

[0081] The nozzle inner barrel (7) and the nozzle outer barrel (6) are hollow cylinders. The diameter of the nozzle inner barrel (7) is smaller than that of the nozzle outer barrel (6). The nozzle inner barrel (7) is set in the nozzle outer barrel (6), and the nozzle The lower end of the inner barrel (7) is fixe...

Embodiment 3

[0085] The upper end of the nozzle inner barrel (7) and the upper end of the nozzle outer barrel (6) are provided with an upper flange bracket (19), and one end of the upper flange bracket (19) is an annular closing plate (20), which is in the shape of an eye ring and is closed in a ring. At least 3 flange plates (21) are arranged at equal intervals on the plate (20), the flange plates (21) protrude on the annular closed plate (20), and the flange plates (21) are concave-shaped gaps between them. Form the air inlet (3).

[0086] The outer wall of the upper end of the sprinkler inner barrel (7) is fixedly connected with the inner side of the upper flange bracket (19), and the inner wall of the upper end of the sprinkler outer barrel (6) is fixedly connected with the outer side of the upper flange bracket (19). The annular closing plate (20) of the flange bracket (19) closes the air inlet passage (4) formed by the upper end of the inner barrel (7) of the nozzle and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com