Rolling procedure making method of aluminium single-stand cold-rolling machine

A rolling schedule, single-stand technology, applied in the field of rolling schedule formulation strategy, can solve problems such as long calculation time, consideration of rolling parameters, and difficulty in adapting to the rolling process of an aluminum single-stand cold rolling mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The invention proposes a method for formulating a rolling schedule for an aluminum single-stand cold rolling mill, and the rolling schedule is formulated on the basis of the rolling specification.

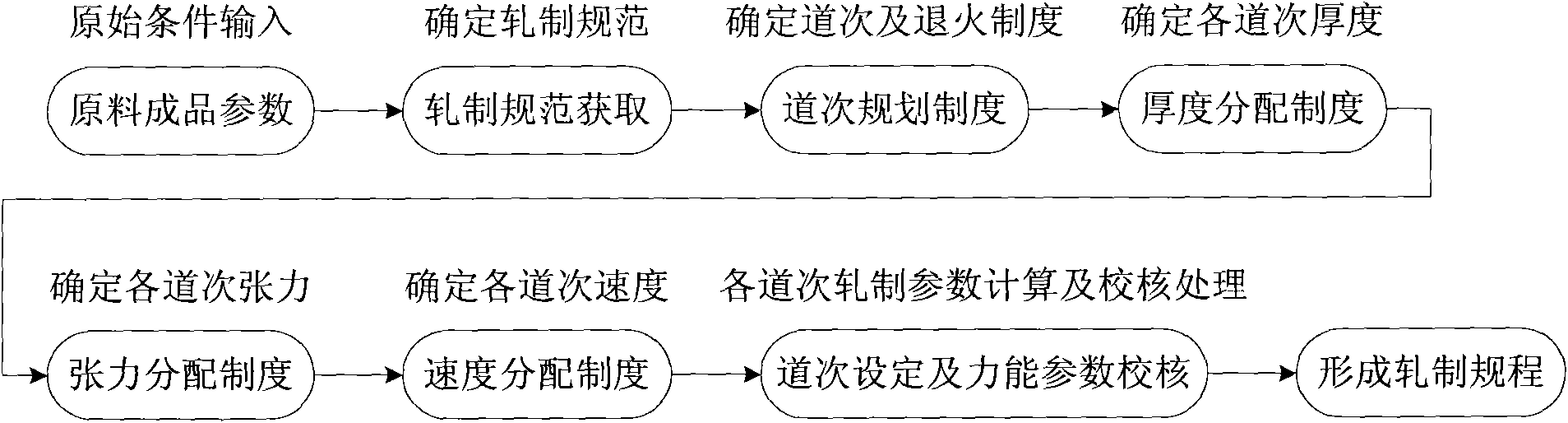

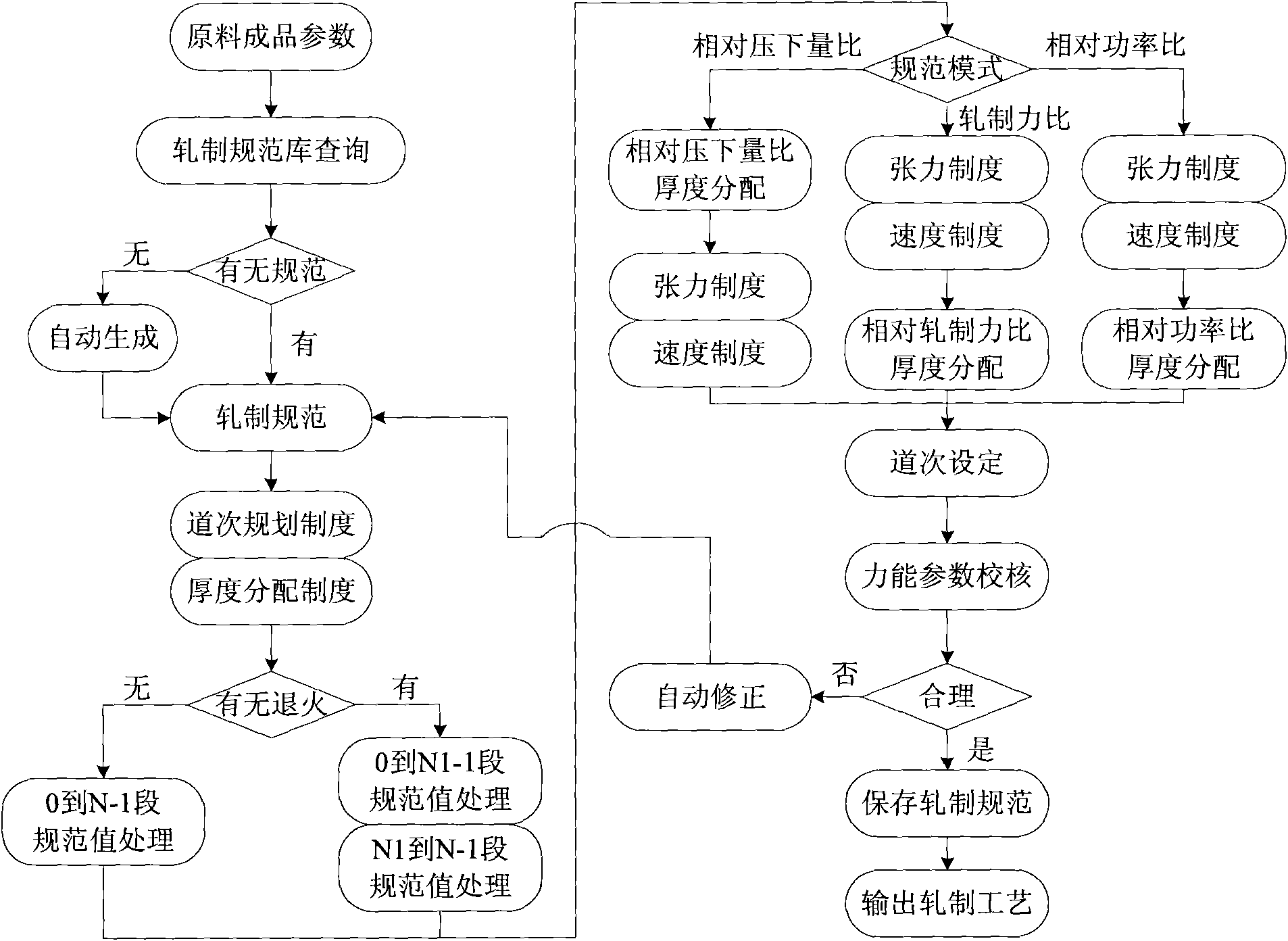

[0090]According to the rolled material and specifications, after the rolling specifications are automatically generated or obtained from the rolling specification database, the pass planning system determines the overall pass and annealing pass arrangement, and the thickness distribution system completes the uncertain pass number of each pass section. Thickness allocation of each pass, combined with the tension system and speed system to complete the design of rolling parameters such as thickness, tension, and speed of each pass, and check the force and energy after generating the rolling schedule, and adjust the rolling specification until each rolling schedule The rolling parameters meet the process constraints, and the rolling schedule is output, such as figure 1 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com