Method for repairing collecting ring on line

A collector ring and insulating baffle technology, applied in the direction of collector maintenance, etc., can solve the problems of loss of enterprise benefit, influence on motor operation, surface damage of collector ring, etc., so as to shorten the repair period, improve work efficiency and enterprise benefit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] During the running process of the motor, many potholes are formed on the surface of the collector ring due to the action of the electric arc. The irregular deep pits cause the brush jumping during the motor operation. Online repair, the specific steps are:

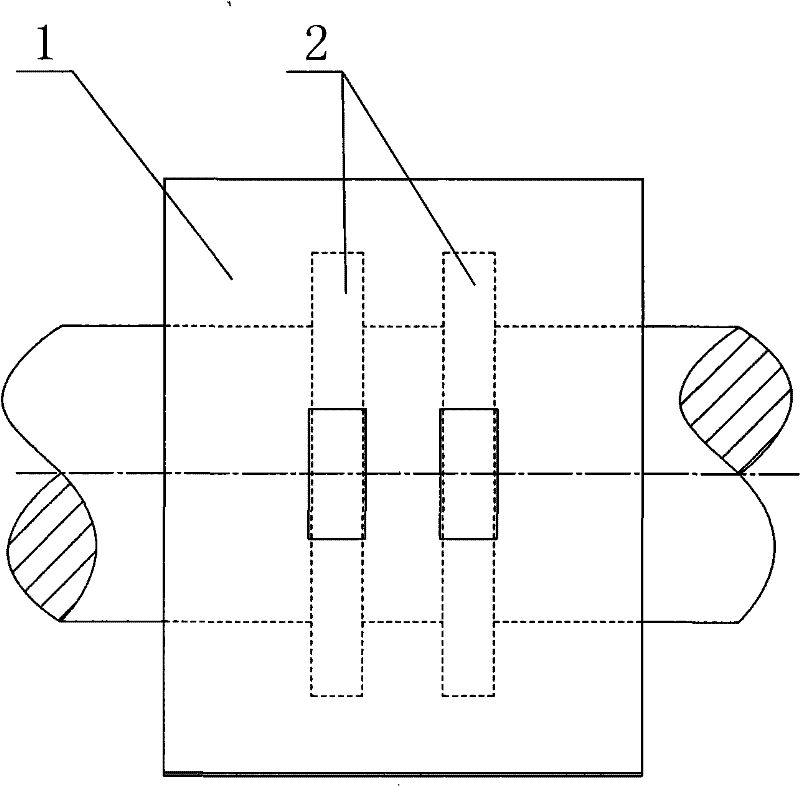

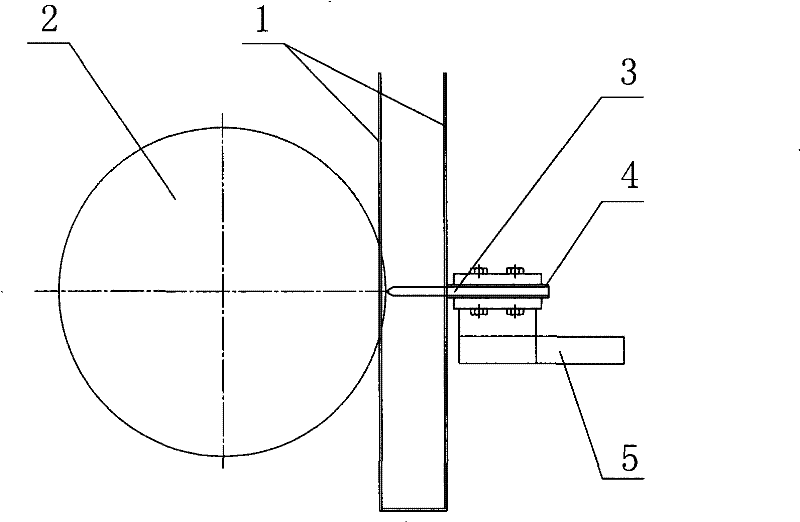

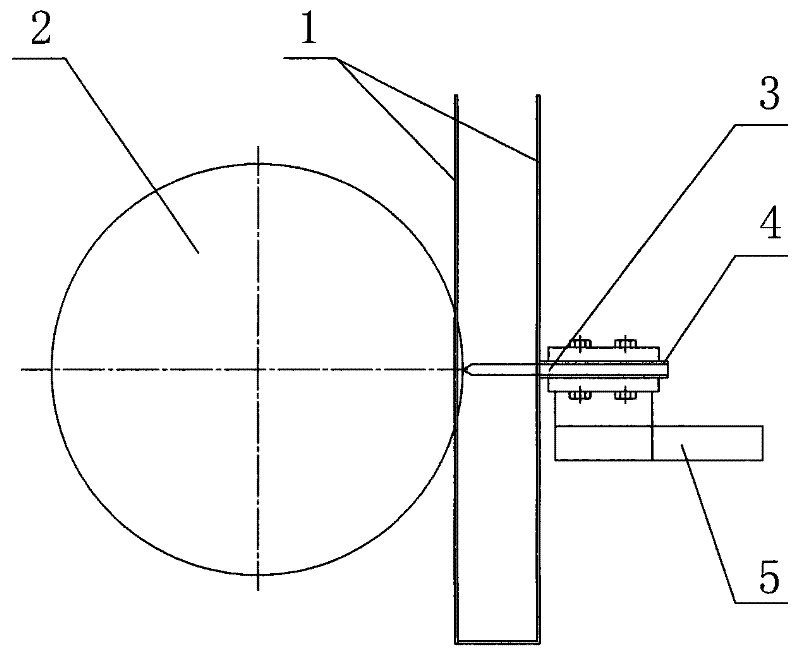

[0012] ① Fix two insulating baffles 1 perpendicular to the horizontal plane on the outer side of the collector ring 2 to be repaired, and the bottom of the two insulating baffles is a sealed structure; ensure that the cuttings do not come into contact with any conductor;

[0013] ② Open a hole on the insulation baffle 1, the position of the hole corresponds to the collector ring 2 to be repaired, and the gap between the opening of the insulation baffle 1 and the two sides of the collector ring 2 is ≤1mm; the collector ring 2 The distance b=2-4mm to expose the insulating baffle 1;

[0014] ③Use a grinder to grind the surface of the collector ring through the hole on the insulating baffle, polish the surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com