Automatically-recording type ventilating dry humidity device

A technology for ventilation, dryness and wetness and automatic recording. It is applied in the directions of thermometers, measuring devices, and electrical devices. It can solve the problems of not reaching the micro-change state process, not reaching the value of the micro-change state process, and low sensitivity. Sensitivity and accuracy, the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

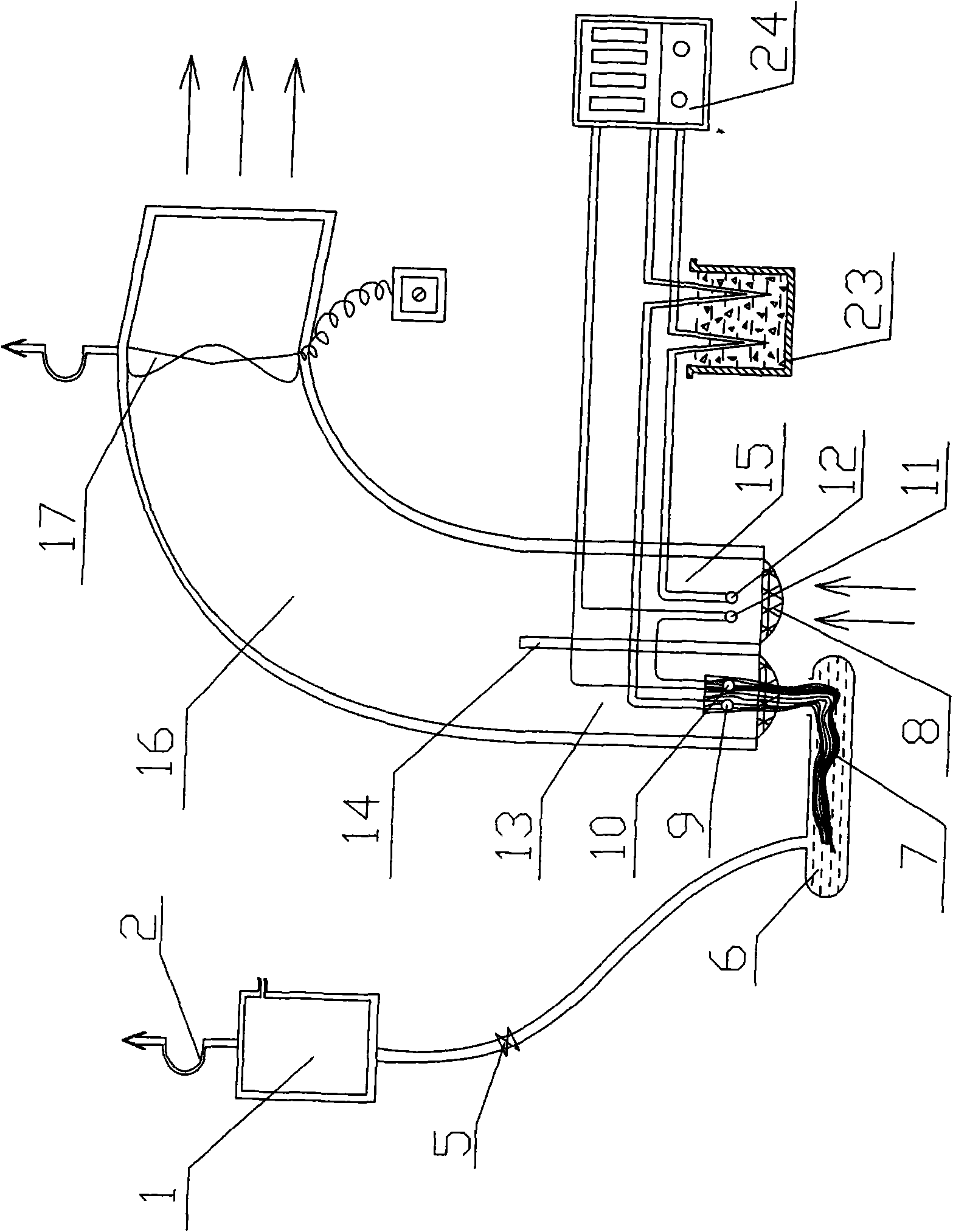

[0022] The accompanying drawing is an embodiment of the present invention, and this embodiment will be described in detail in conjunction with the accompanying drawings, including a large water reservoir 1, a hook 2, a regulating valve 5, a small water reservoir 6, an air duct pipe 16, a partition 14, and a fan 17. Net cover 8, thermocouple wet bulb 9, thermocouple temperature difference wet bulb 10, thermocouple temperature difference dry bulb 11, thermocouple dry bulb 12, moisturizing gauze 7, digital acquisition record processor 24 and thermostat 23; Among the examples, the large water storage device 1, the hook 2, the regulating valve 5 and the small water storage device 6 form a moisturizing device, and the upper end side of the large water storage device 1 is provided with a water filling and gas balance port, and the upper end of the large water storage device 1 The end face is provided with a hook 2 fixedly connected with it, the large water storage 1 is set to be conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com