Piston and internal combustion engine of circular slider-crank mechanism

A crank round slider and round slider technology, applied in the directions of pistons, cylindrical pistons, machines/engines, etc., can solve the problems of bulkiness, poor balance performance, bulky internal combustion engines and compressors, etc., to reduce stress and improve bearing capacity. ability, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

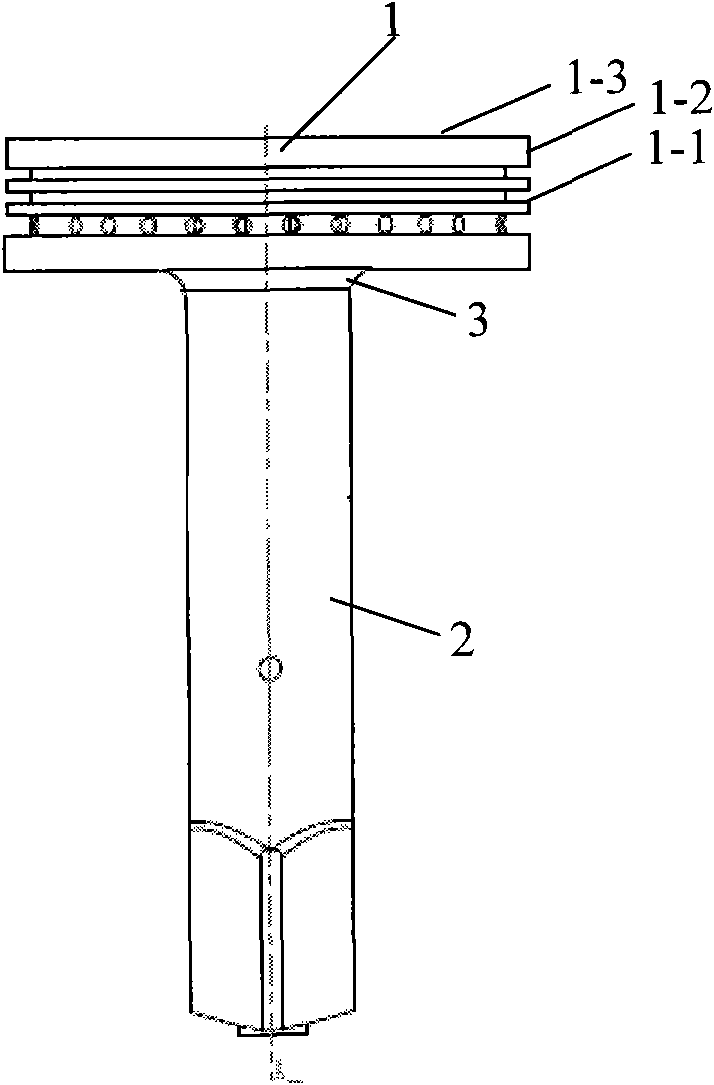

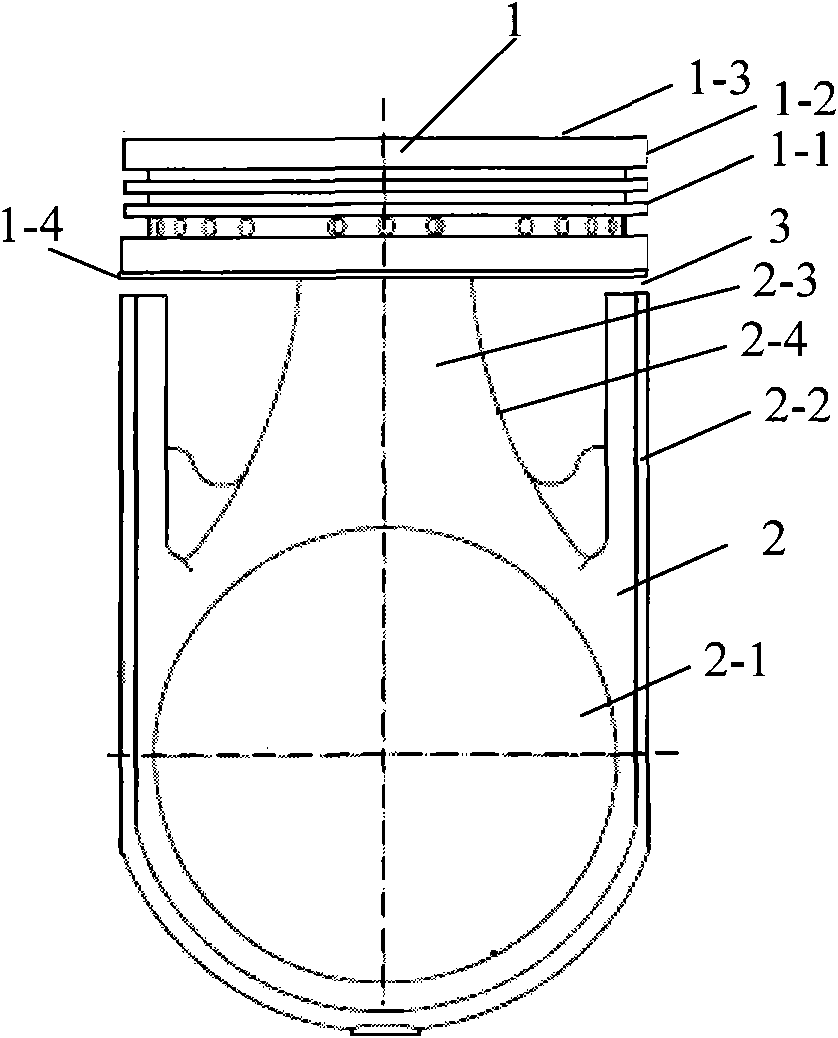

[0035] figure 1 It is the front view of the piston of the slider crank mechanism of the first embodiment of the present invention, figure 2 It is a left side view of the piston of the slider crank mechanism of the first embodiment of the present invention. in, figure 1 and figure 2 Shown in is a single-acting piston, ie a piston crown is provided at only one end of the piston seat. It should be understood that the piston of the present invention may also be a double-acting piston, that is, a piston crown is also provided at the other end of the mounting seat. In this embodiment, only one end of the mounting seat is provided with a piston crown as an example to illustrate the piston of the crank-slider mechanism of the present invention, and the other end of the piston mounting seat can also be the same as or similar to that of the first embodiment of the present invention. An additional crown is provided, forming a double-acting piston.

[0036] Please refer to figure ...

Embodiment 2

[0050] In this embodiment, the strength of the piston crown is enhanced by arranging reinforcing ribs at the bottom of the piston crown. Wherein, the reinforcing ribs may be strip ribs radiating from the center of the bottom of the crown to the periphery. In this embodiment, a cross beam is taken as an example for description. It should be understood that the reinforcing ribs may also be other strip-shaped ribs, such as rice-shaped ribs. Certainly, the reinforcing rib may also be in other shapes, such as a plate shape. It is not described here one by one, and those skilled in the art can set reinforcing ribs of different shapes according to the teaching of the description of the present invention and in combination with actual needs.

[0051] image 3 It is a front view of the piston of the slider crank mechanism of the second embodiment of the present invention.

[0052] Such as image 3 As shown, the piston of this embodiment includes a piston seat 2 and a crown 1 arran...

Embodiment 3

[0060] Figure 5 It is the front view of the piston of the slider crank mechanism of the third embodiment of the present invention. Figure 6 It is the left side view of the piston of the slider crank mechanism of the third embodiment of the present invention.

[0061] Please refer to Figure 5 and Figure 6 , In the embodiment of the present invention, the piston of the crank-slider mechanism includes a mounting base 2 and a crown 1 . The crown 1 is disposed at one end of the mounting base 2 . The other end of the mounting base 2 can be suspended, or a counterweight insert can be set, and another crown can be installed in the same way as any of the methods in this specification or in other ways to form a double-acting piston.

[0062] Wherein, the crown 1 and the mounting seat 2 can be integrally formed, or can be fixedly assembled together by means of riveting or screwing. In this embodiment, the crown 1 and the mounting base 2 are integrally formed as an example for il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com