Method for controlling combustion noise in a compression-ignition engine

A combustion engine, combustion noise technology, applied in the direction of combustion engine, internal combustion piston engine, engine control, etc., can solve problems such as high pressure, increased noise level, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

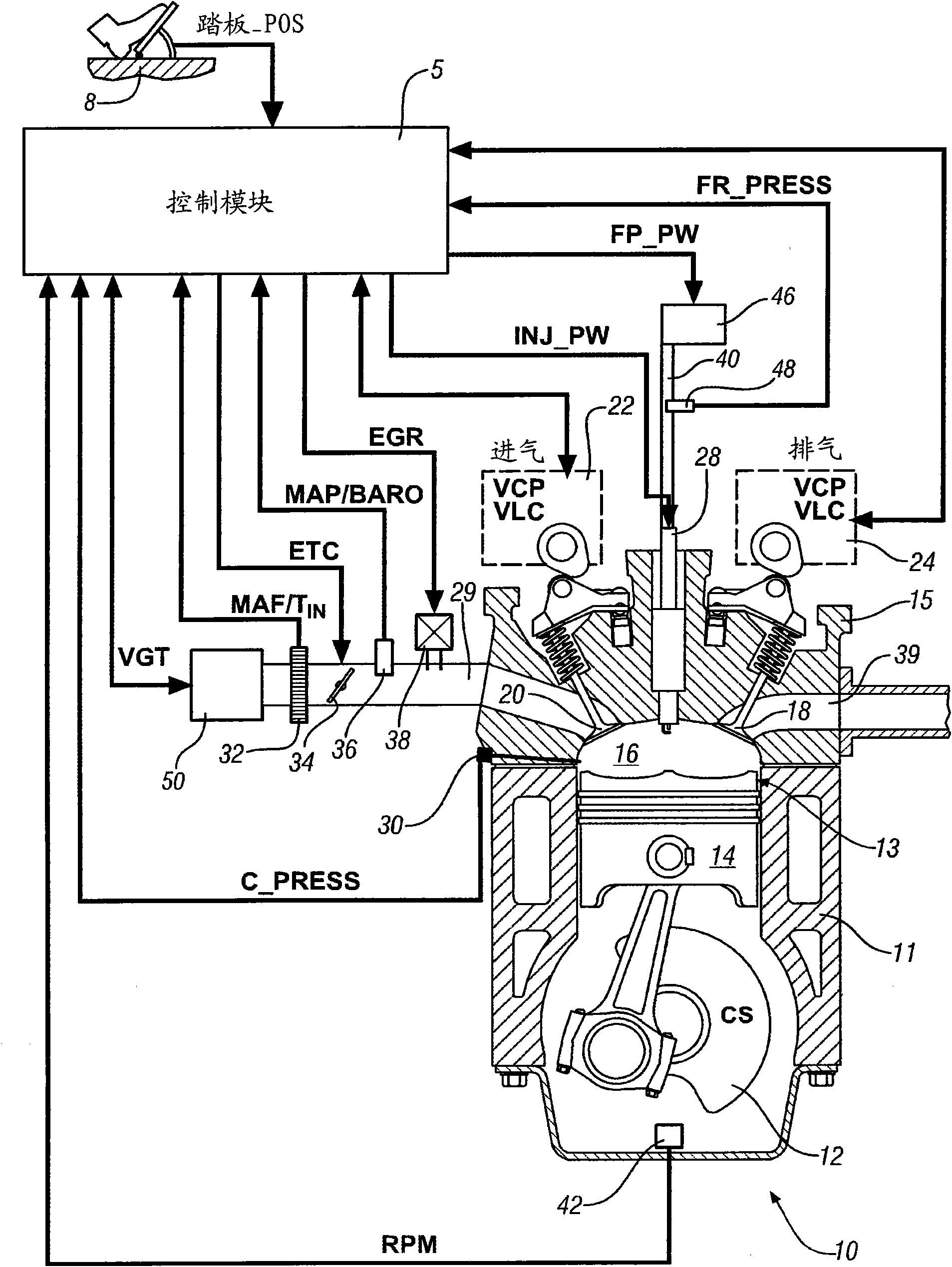

[0011] [0011] Referring now to the drawings, in which the illustrations are for the purpose of illustrating certain exemplary embodiments only and are not intended to be limiting, figure 1 A compression ignition internal combustion engine 10 and a control module 5 are schematically shown. Exemplary internal combustion engine 10 includes a multi-cylinder arrangement including an engine block 11 , a crankshaft (“CS”) 12 and cylinder heads 15 . In the engine block 11 are formed a plurality of cylinders 13 each having a piston 14 slidably movable therein. Each piston 14 is mechanically operatively connected via a piston rod to the crankshaft 12, and the crankshaft 12 is mounted to the engine block 14 on main bearings and rotates therein. The linear reciprocating motion of piston 14 is converted into rotational motion of crankshaft 12 . The intake system directs the intake air to the intake manifold 29 which directs and distributes the intake air to a plurality of intake runners....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com