Method for preparing nanometer titanate with controllable appearances by utilizing industrial raw materials

A technology of titanate and raw materials, which is applied in the field of preparing various titanates with controllable morphology, achieving the effect of low cost and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

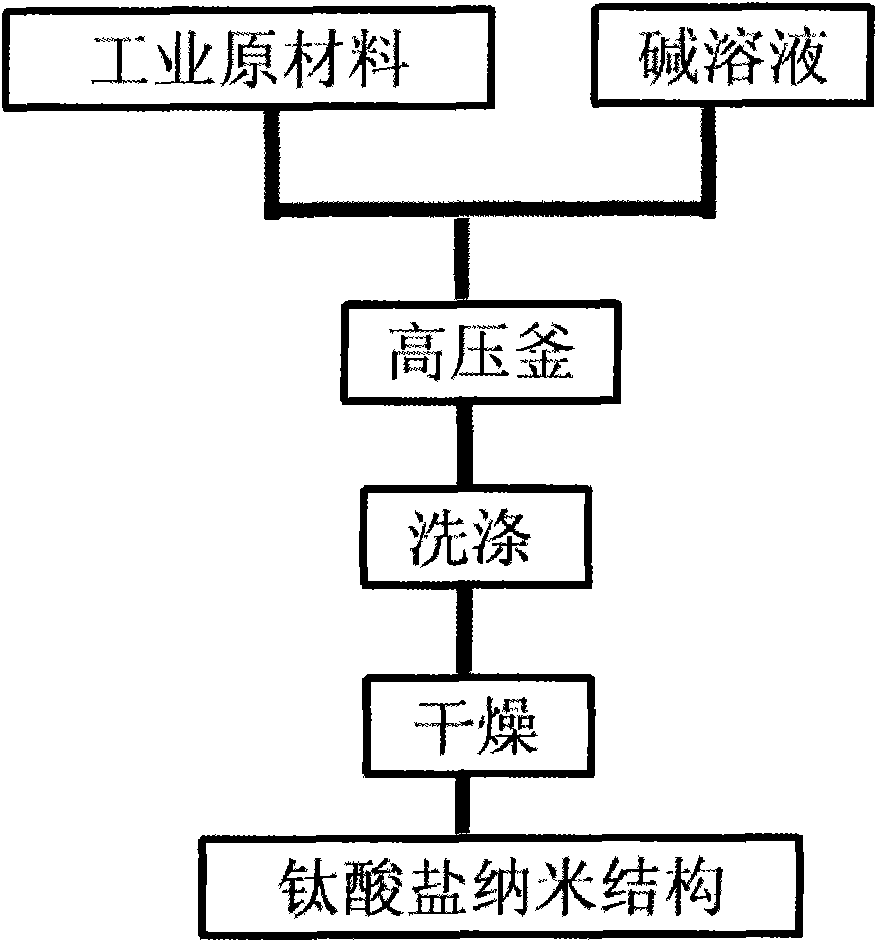

[0078] The following takes an autoclave with a volume of 50ml as an example to illustrate the preparation steps of various titanate nanostructures, see figure 1 .

[0079] 1. Preparation of titanate nanobelts

[0080] (1) Weigh 1-3 g of metatitanic acid and put it into an autoclave.

[0081] (2) Prepare a NaOH solution with a molar concentration of 9-11 M, and add 35-40 ml into the autoclave.

[0082] (3) Magnetically stir the raw materials in the autoclave for 1-2 hours to form a uniform white suspension.

[0083] (4), put the autoclave into the environment of 170~220 ℃, keep warm for more than 20 hours;

[0084] (5), after the reaction is over, after the temperature of the kettle is naturally lowered to room temperature, the autoclave is opened and the solution is poured out.

[0085] (6), filter or centrifuge to separate the precipitate, wash with water several times until the pH of the solution is neutral.

[0086] (7) The precipitate is dried to obtain the product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com