Method for purifying and reclaiming carbon dioxide from landfill gas and device thereof

A landfill gas and carbon dioxide technology, applied in chemical instruments and methods, separation methods, liquefaction, etc., can solve problems affecting the environment, waste of resources, complex composition of landfill gas, etc., achieve a wide range of applications and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

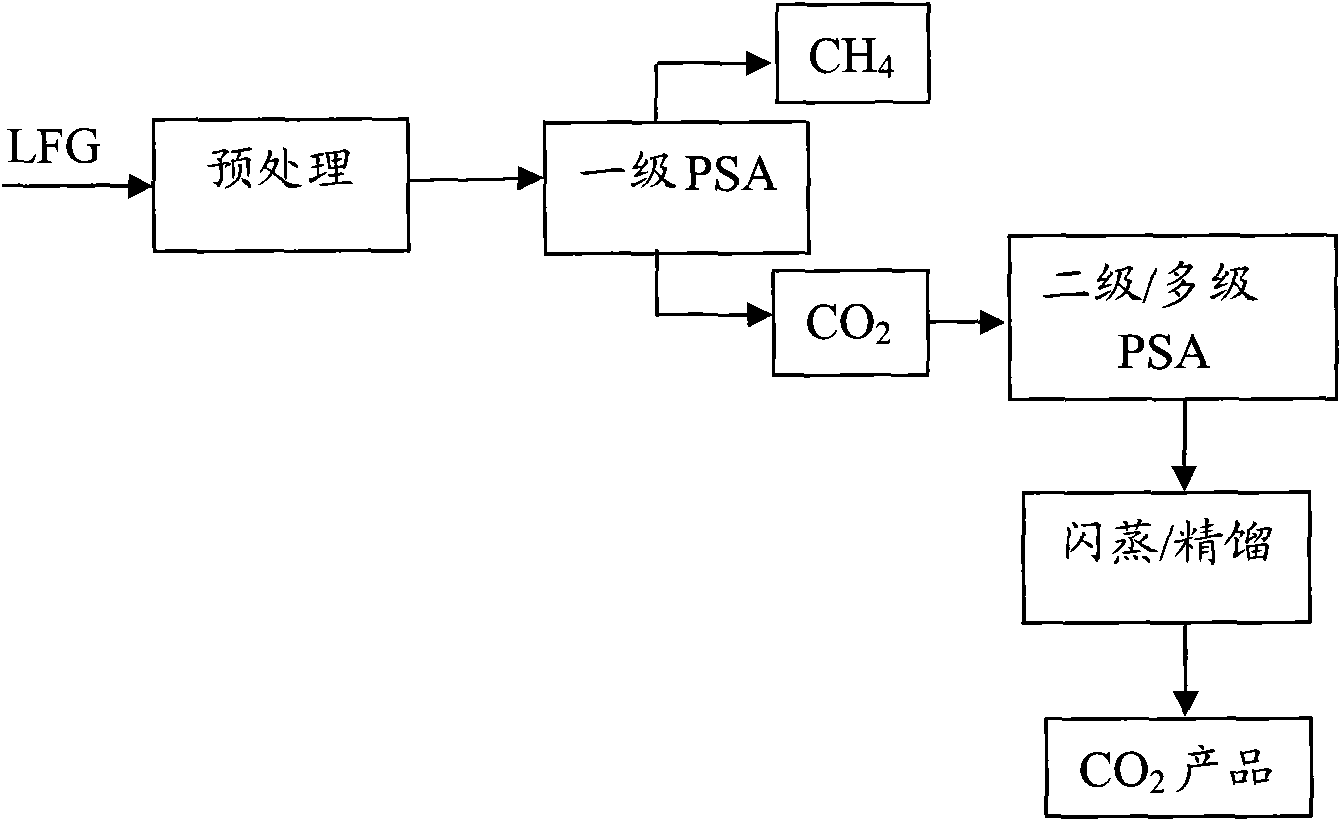

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

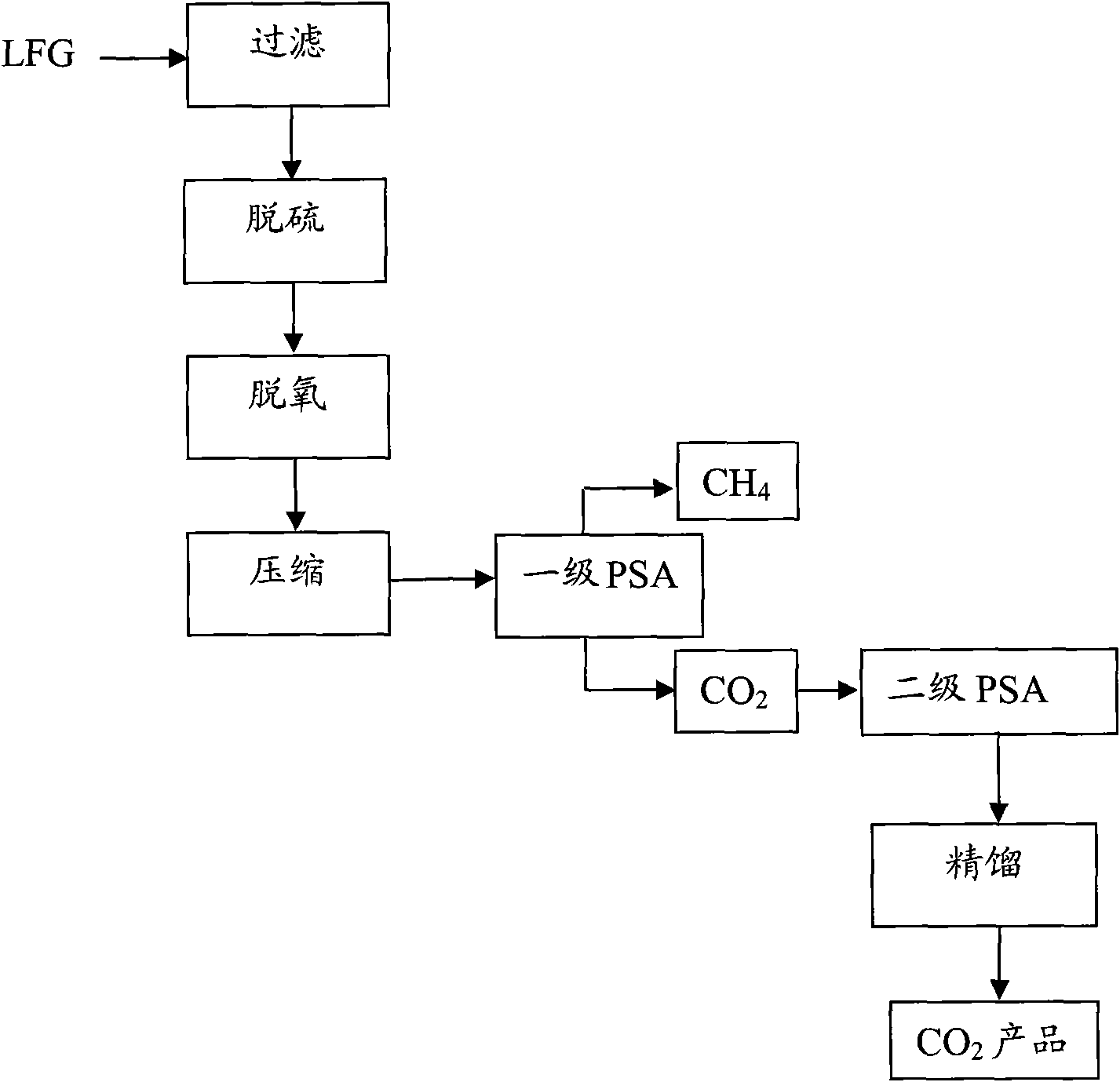

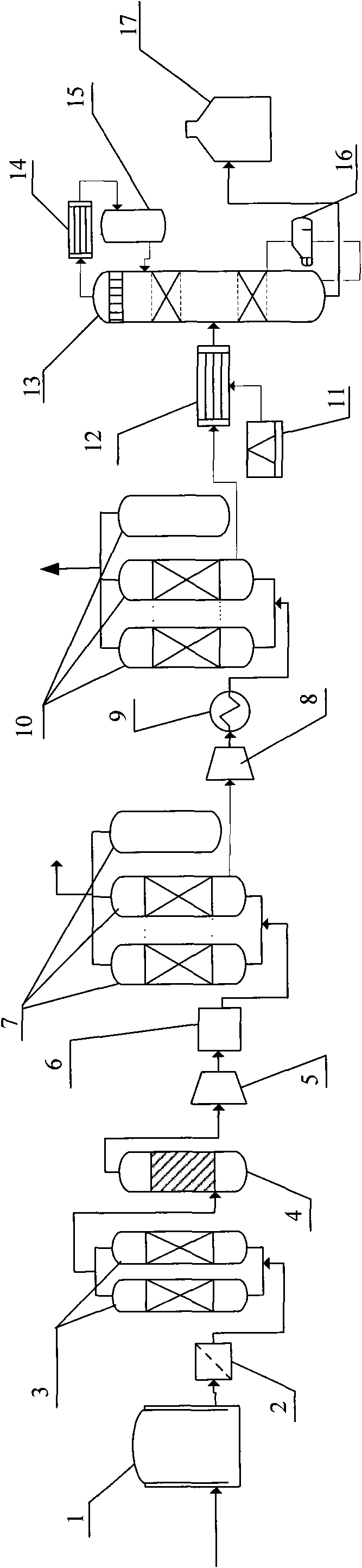

Embodiment 1

[0063] After desulfurization, deoxidation, compression and other pretreatment steps, the feed gas enters the first-stage pressure swing adsorption unit, the adsorption pressure is 0.3MPa, the adsorption time is 100s, and then the gas containing 91% CH 4 The adsorbed gas is collected from the top of the tower; the pressure in the tower is equalized, reversed, and reduced to normal pressure, and the CO in the desorbed gas obtained from the bottom of the tower 2 The content is 70%, the remainder is N2, O2 and CH 4 ; The desorbed gas enters the two-stage PSA unit, the operating conditions are the same as that of the program, the adsorbed gas is discharged from the top of the tower, and the CO in the desorbed gas discharged from the bottom of the tower is 2 Increase to 91%, continue to use rectification for purification, and finally obtain food-grade liquid CO with a purity of 99.993% 2 .

Embodiment 2

[0065] After desulfurization, deoxidation, compression and other pretreatment steps, the feed gas enters the primary pressure swing adsorption unit, the adsorption pressure is 1.2MPa, the adsorption time is 280s, and then the gas containing 93% CH 4 The adsorbed gas is collected from the top of the tower; the pressure in the tower is equalized, reversed, and reduced to normal pressure, and the CO in the desorbed gas obtained from the bottom of the tower 2 The content is 73%, the remainder is N2, O2 and CH 4 ; The desorbed gas enters the two-stage PSA unit, the operating conditions are the same as that of the program, the adsorbed gas is discharged from the top of the tower, and the CO in the desorbed gas discharged from the bottom of the tower is 2 Increase to 92%, continue to use rectification for purification, and finally obtain food-grade liquid CO with a purity of 99.996% 2 .

Embodiment 3

[0067] After desulfurization, deoxidation, compression and other pretreatment steps, the feed gas enters the primary pressure swing adsorption unit, the adsorption pressure is 2.0MPa, the adsorption time is 300s, and then the gas containing 95% CH 4 The adsorbed gas is collected from the top of the tower; the pressure in the tower is equalized, reversed, and reduced to normal pressure, and the CO in the desorbed gas obtained from the bottom of the tower 2 The content is 77%, the remainder is N2, O2 and CH 4 ; The desorbed gas enters the two-stage PSA unit, the operating conditions are the same as that of the program, the adsorbed gas is discharged from the top of the tower, and the CO in the desorbed gas discharged from the bottom of the tower is 2 Increase to 93%, continue to use rectification for purification, and finally obtain food-grade liquid CO with a purity of 99.999% 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com