Finished product collecting device of adhesive film forming machine

A molding machine and collection technology, applied in the field of finished product collection devices, can solve the problems of uneven manual stacking, labor-intensive, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

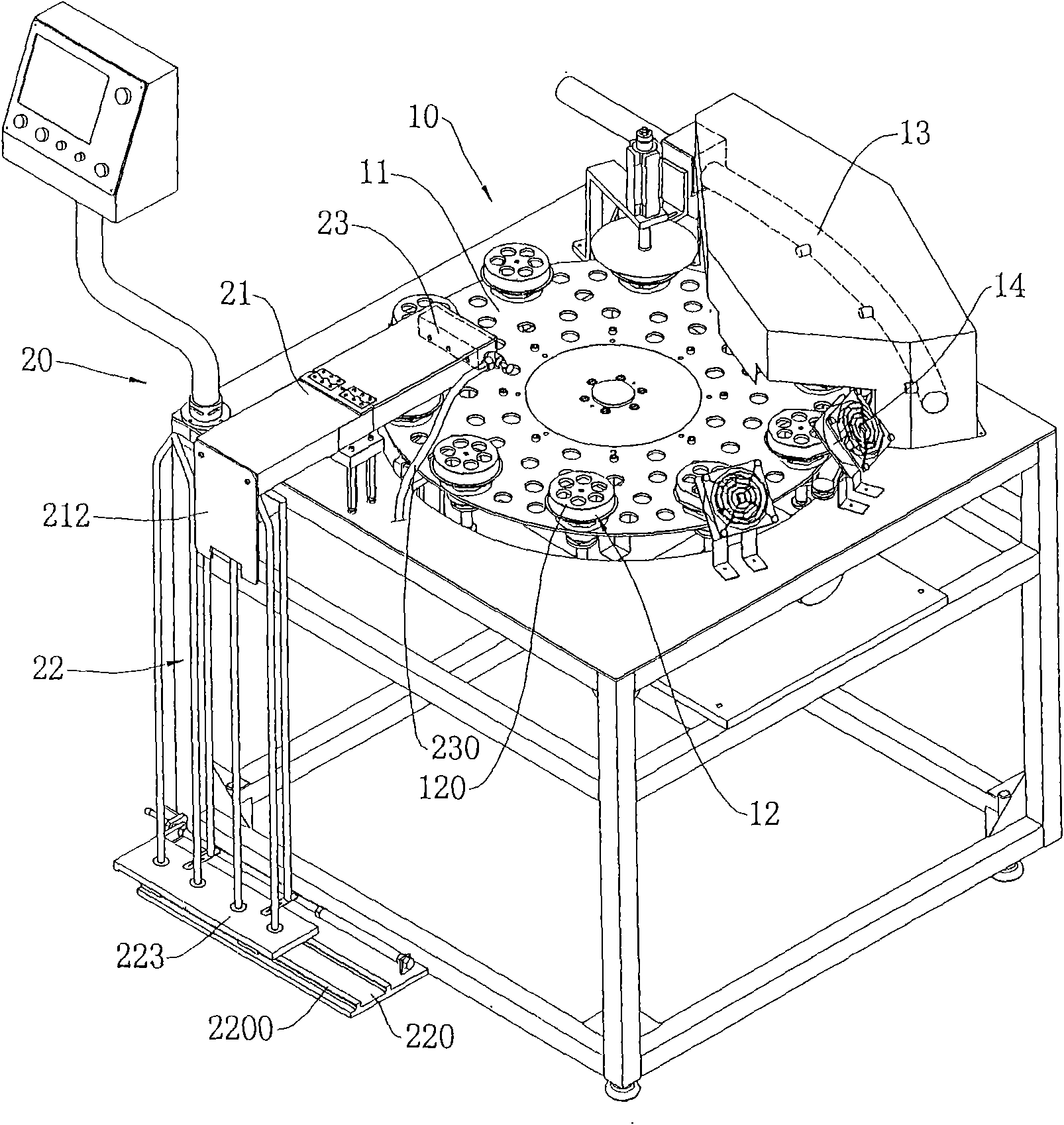

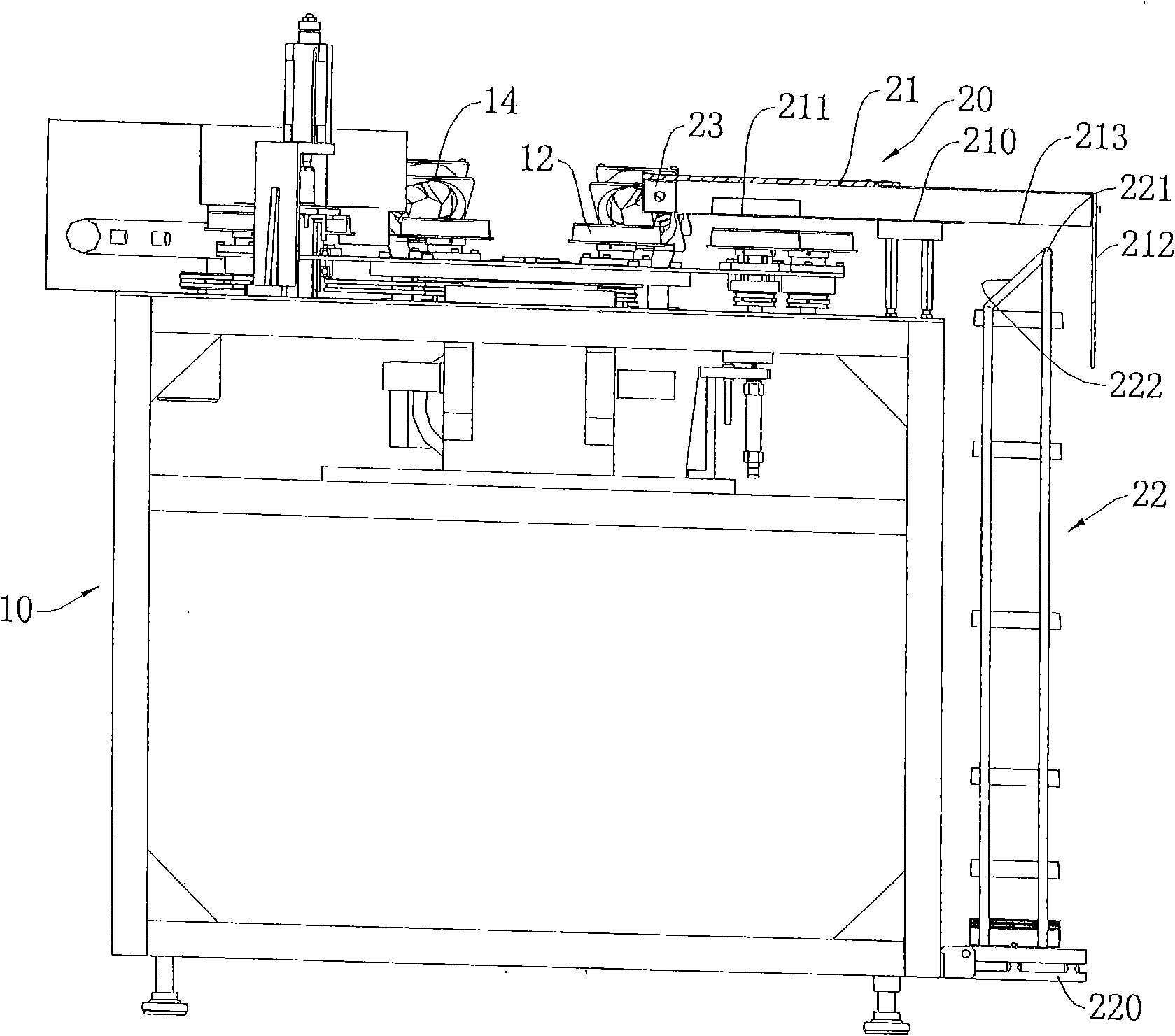

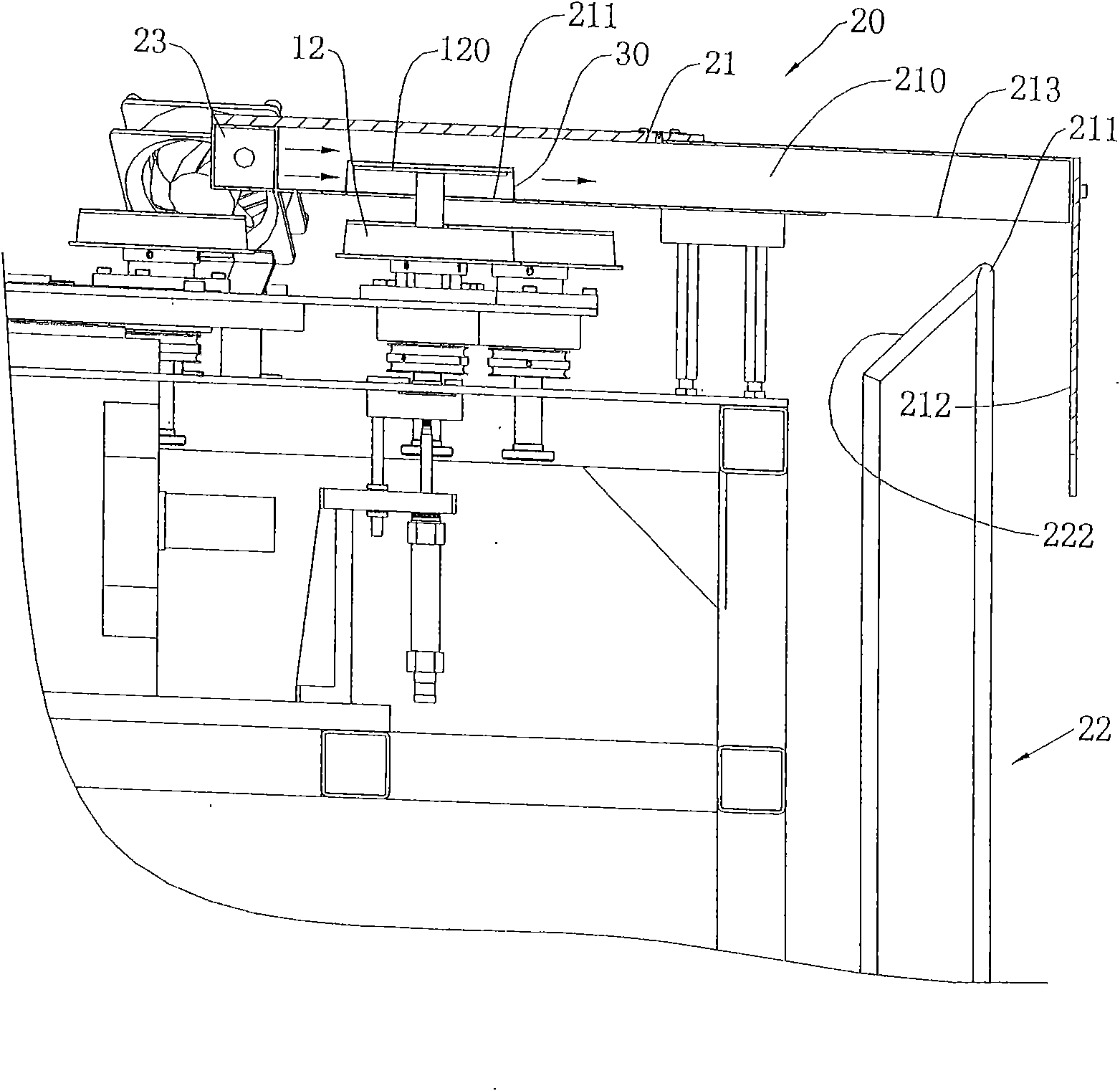

[0028] Please see figure 1 , 2 and image 3 As shown, the adhesive film forming machine of the present invention mainly includes a body 10 and a collecting device 20, wherein:

[0029] The machine body 10 has a power device, and its top surface is provided with a feed plate 11, a plurality of molds 12, a hot air pipe 13 and a plurality of fans 14; wherein, the feed plate 11 is connected with the power device and can be rotated at certain intervals a certain angle; the molds 12 are arranged at intervals on the feed plate 11, and can pivot freely relative to the feed plate 11. They are disc-shaped respectively, a cylinder is provided at the bottom and a lifting plate 120 is provided at the top. The lifting tray 120 can be raised by the action of the cylinder; the hot air pipe 13 is connected to a hot blast generating device (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com