Method for manufacturing needle bearing

A manufacturing method and technology of needle roller bearings, applied in the direction of manufacturing tools, grinding machines, grinding/polishing equipment, etc., to achieve the effects of improving parallelism, preventing axial movement, and fine metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

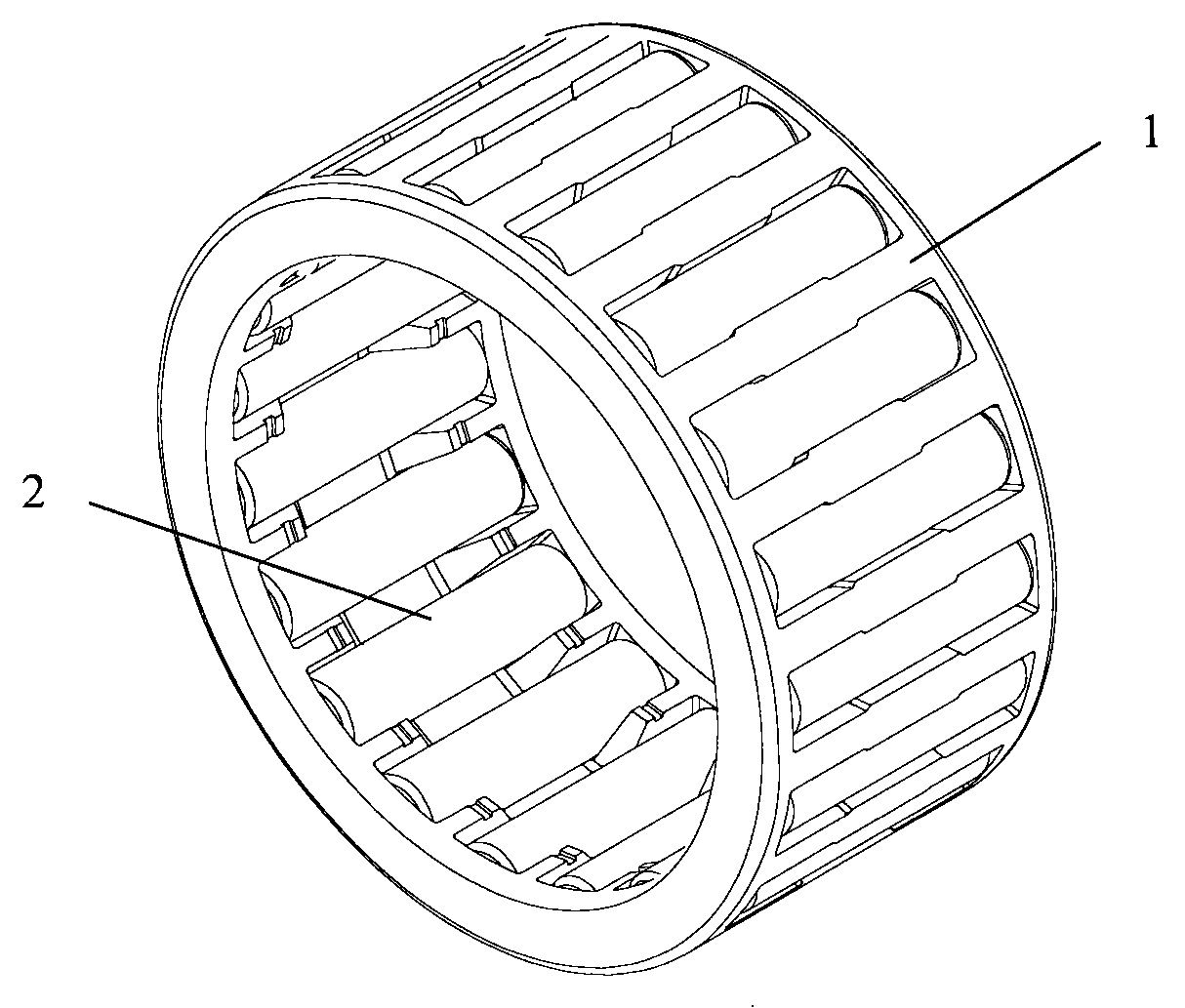

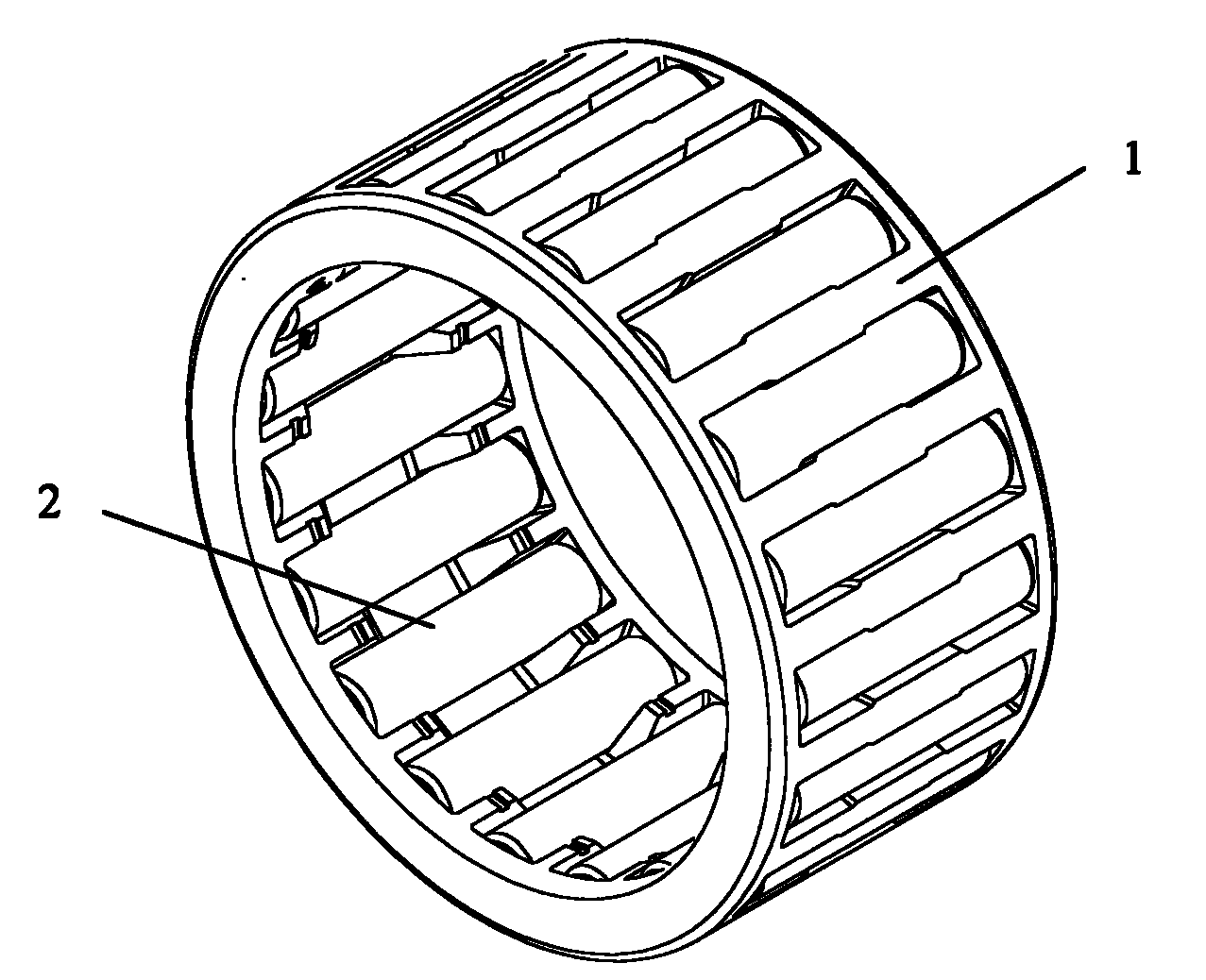

[0019] figure 1 with figure 2 It is the cage 1 and the needle roller 2 of the needle roller bearing in the present invention, wherein the cage is made of 20CrMo alloy steel, and the needle roller is made of GCr15 alloy steel.

[0020] The manufacturing process of the cage is roughly divided into the following steps:

[0021] 1. Process the circular blank on the machine tool;

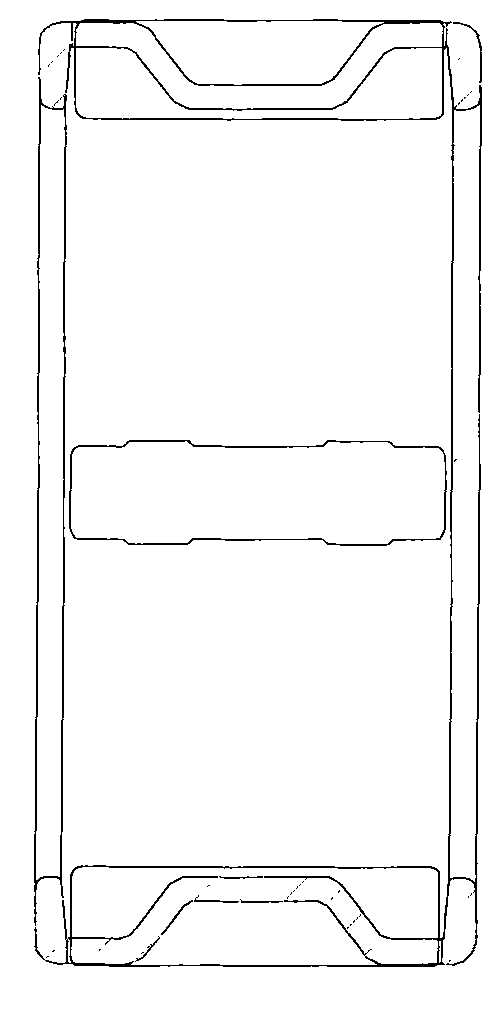

[0022] 2. Cut grooves on the inner and outer sides of the cage blank respectively, so that the cross section is "M" shaped (see figure 2 );

[0023] 3. Process evenly distributed needle grooves on the circumference of the cage blank;

[0024] 4. Carry out metal surface treatment to ensure roughness.

[0025] In the above step 3, special attention should be paid to ensure that the machined needle roller groove is kept parallel to the central axis of the bearing. For this reason, it is necessary to control the parallelism of the lower mold and upper mold tool used to fix the blank of the cage. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com