Boss embedding type diaphragm filter plate

A diaphragm filter plate and inlay technology, which is applied in the field of boss inlaid diaphragm filter plates, can solve the problems of deformation, cracks and fractures of the filter plates, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

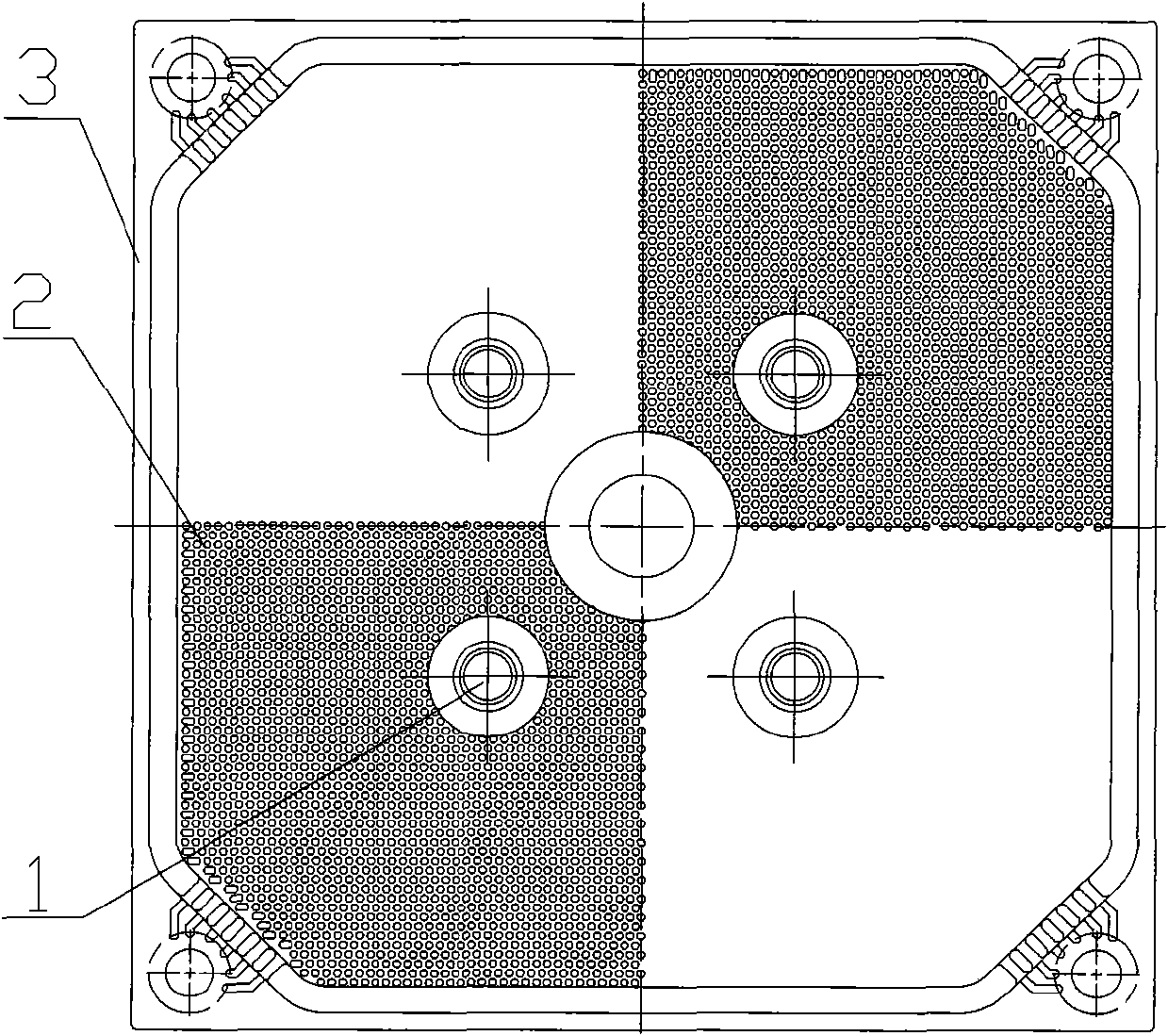

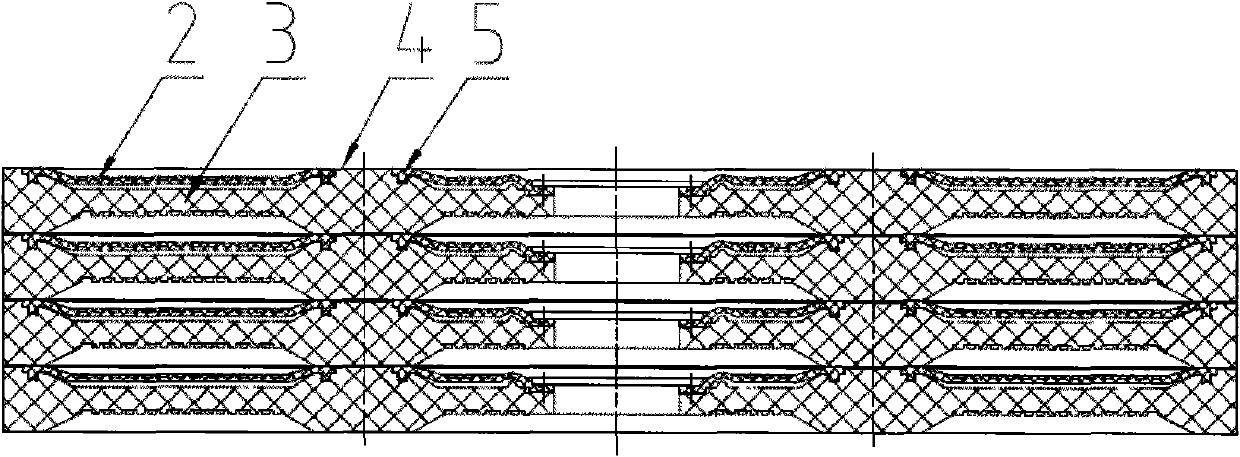

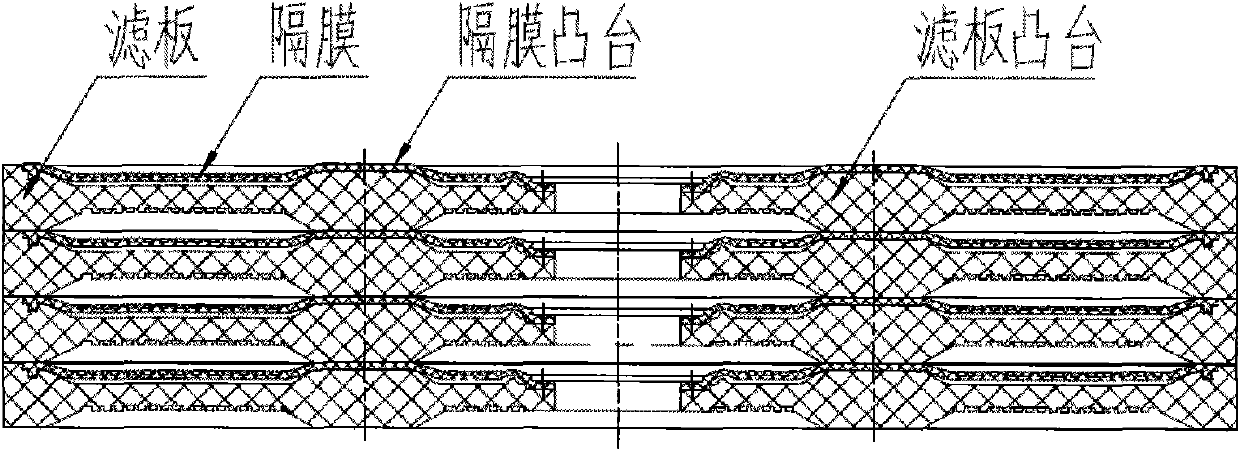

[0010] Embodiment 1: with reference to attached figure 1 and 2 . The boss-embedded diaphragm filter plate includes a diaphragm 2 and a filter plate 3, and the production of the diaphragm 2 and the filter plate 3 is the prior art, so it will not be described here. The diaphragm 2 is located on one side of the filter plate 3 , the four supporting bosses of the diaphragm are round holes and the round holes are sealed and sleeved on the four supporting bosses 4 in the filter plate 3 . The four on the back of the round hole are formed with a sealing ring 5 and form a sealing fit with the annular groove on the filter plate. The faces of the four supporting bosses 4 are lower than the faces of the diaphragm 2 . A plurality of single-sided diaphragm filter plates are overlapped, and the supporting convex surfaces of the plurality of single-sided diaphragm filter plates are in contact with the supporting convex platforms of the filter plates.

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the groove wall of the annular groove has more than 2 convex rings and is tightly matched with the sealing ring 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com