Guide wire

A technology of guide wire and wire material, which is applied in the field of guide wire with welding structure in the main body, which can solve the problems of complex manufacturing process, high hardness of tubular parts, and affecting the continuity of elasticity, so as to reduce the possibility of vascular injury and increase the welding Combining the area and the effect of improving safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

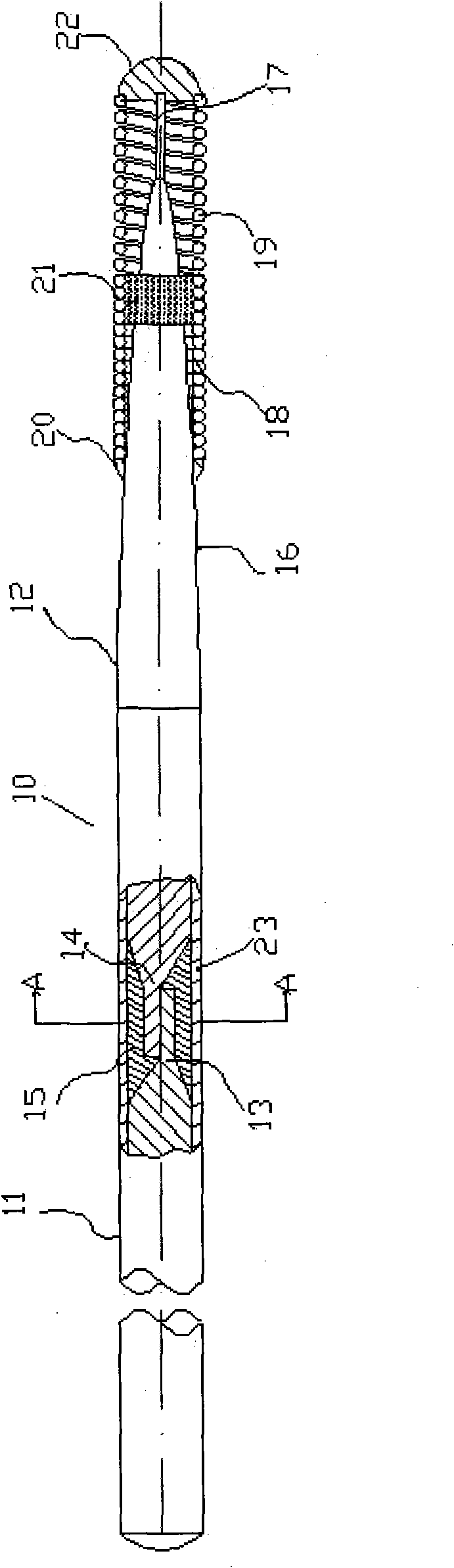

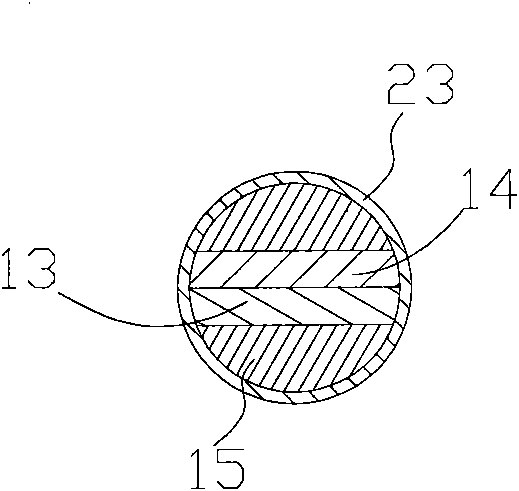

[0017] figure 1 Is a front view showing an embodiment of the guide wire of the present invention, figure 1 The guide wire shown has a guide wire main body 10 and a spring coil 18 and a developed spring coil 19 arranged in sequence at the distal end of the guide wire main body. The guide wire main body 10 is composed of a main structure wire 11 disposed at the proximal end of the guide wire and The main structure wire 12 at the distal end of the guide wire is formed by welding.

[0018] The length of the guide wire body 10 is 90 to 500 cm, preferably 175 cm to 200 cm.

[0019] The outer diameter of the proximal wire 11 of the main structure is uniform, and the distal end of the distal wire 12 of the main structure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com