On-load tapping switch hanger

A technology of on-load tap changer and hanger, which is applied in the direction of transformers, electrical components, variable inductors, etc. It can solve problems such as slowdown, many personnel, and difficult control of crane power, so as to achieve reliable safety performance and save human resources. , The effect of shortening the maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

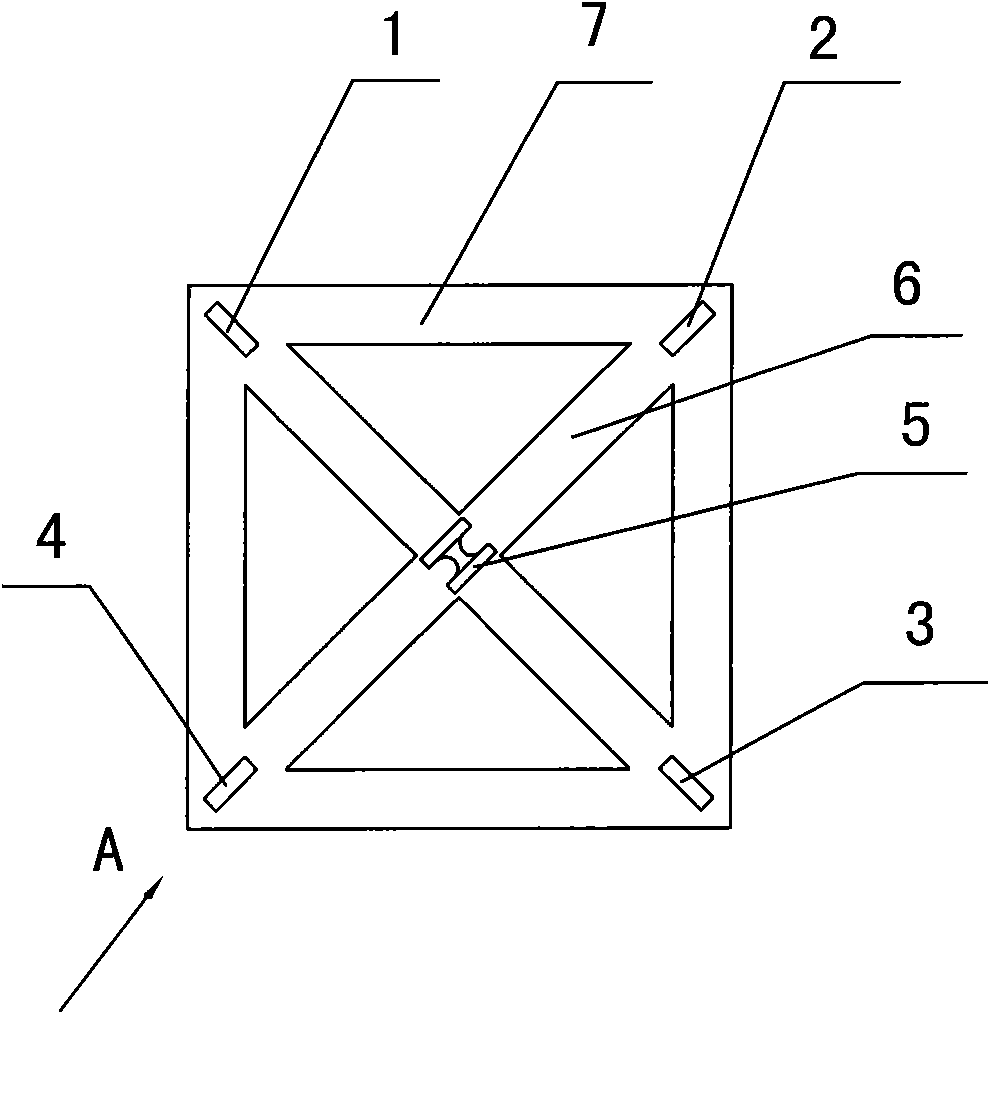

[0013] Figure 1~4 It is a schematic structural diagram of an embodiment of the present invention, and the present invention will be described below in conjunction with the accompanying drawings of the embodiment.

[0014] This on-load tap changer hanger includes a hanger top 16, 4 legs, and components such as a wire tensioner 13 and a pulley.

[0015] Such as figure 1 , figure 2 , the frame 7 of the hanger top 16 is welded by steel pipes. First, four steel pipes are welded into a square, and secondly, two steel pipes are welded on the diagonal part of the frame 7 of the square to form a cross bracket 6 . This cross bracket 6 is a load-bearing part, which can bear 400KG (the tap changer weight is generally 35-75KG). Then weld the pulley 5 at the center position of the cross bracket. This pulley is a fixed pulley, which must be welded firmly and slide smoothly. Finally, four fixing parts (fixing parts 1-4) are welded on the four corners of the square frame to connect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com