Combined photographic cantilever pan tilt

A combined and cantilever technology, applied in the field of photographic equipment, can solve the problems of inconvenient carrying, uncompact structure of the pan/tilt, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

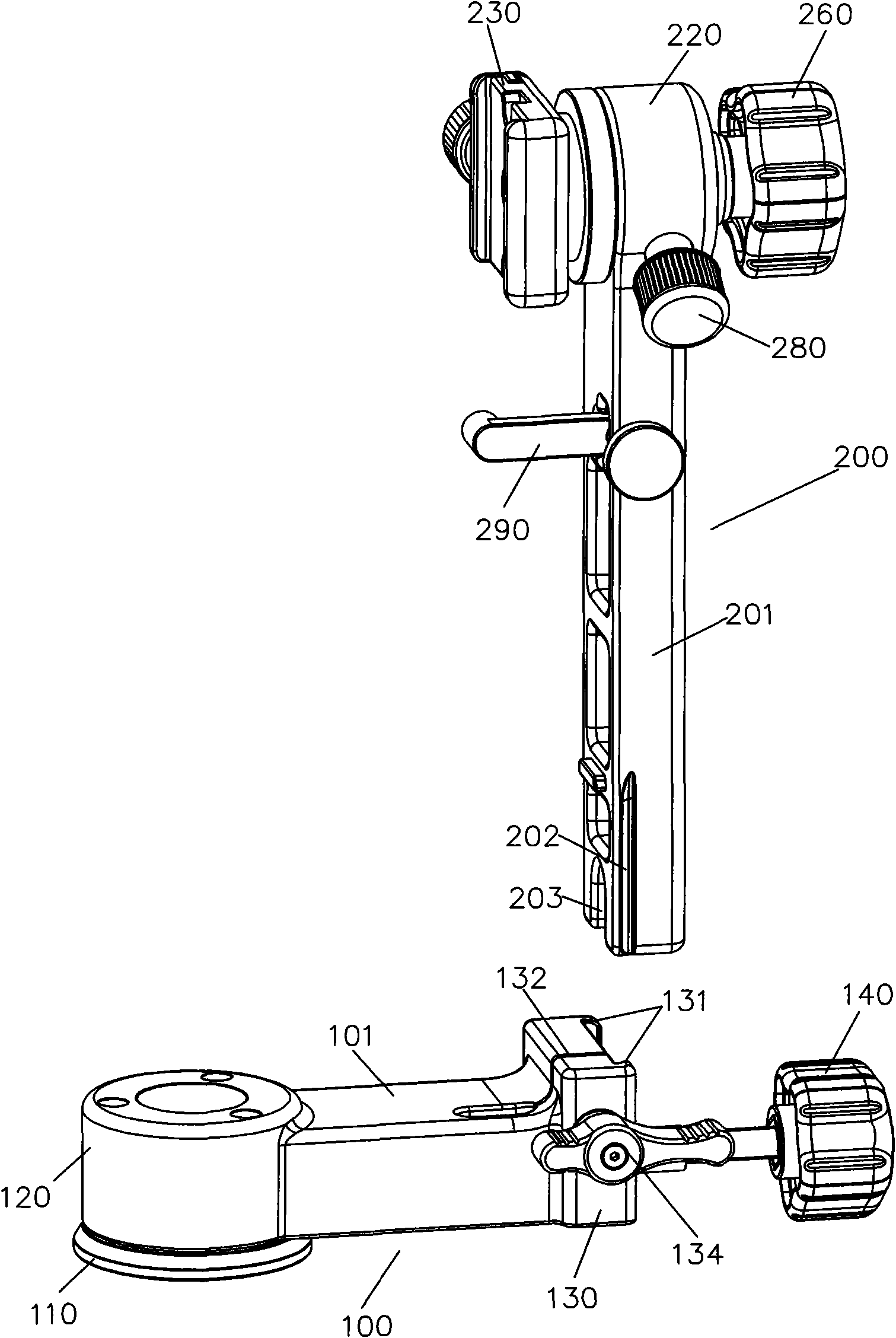

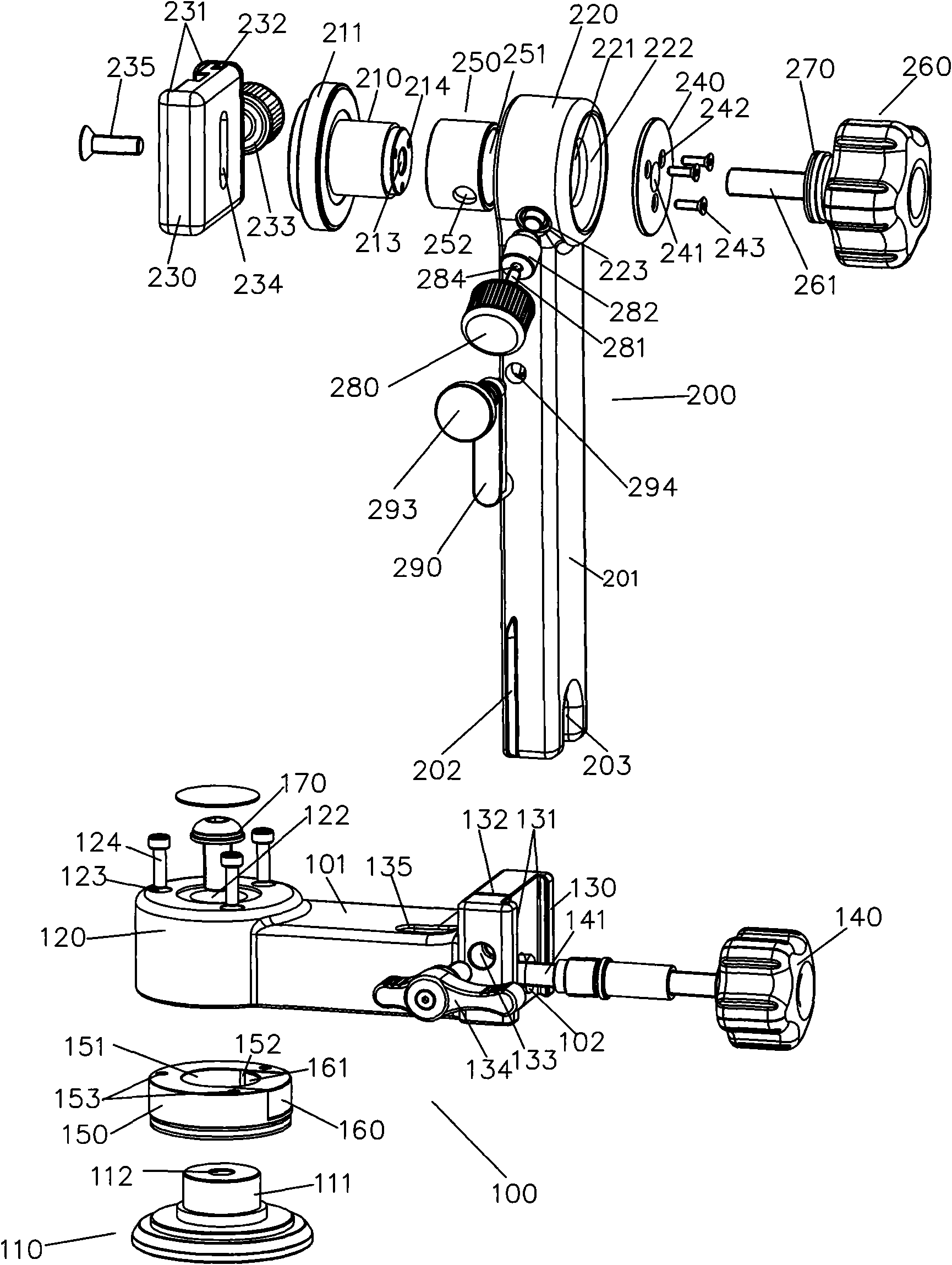

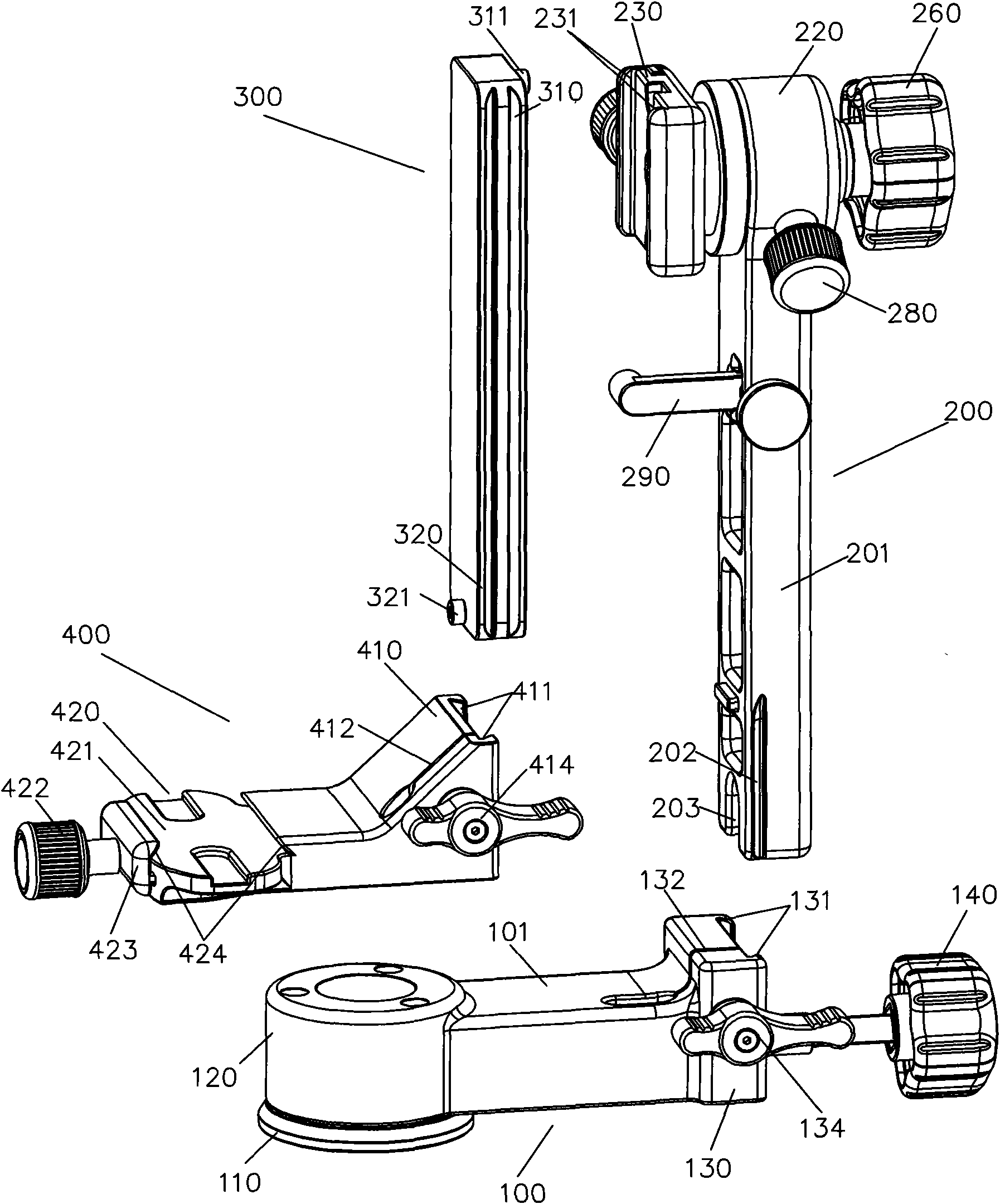

[0025] like figure 1 , figure 2 , Figure 4 As shown, the present invention includes a horizontal support assembly 100 and a vertical support assembly 200 with a free end, and the horizontal rotating support assembly 100 and the vertical support assembly 200 can be separated and combined into an L-shaped support through a flexible connection; wherein:

[0026] The free end of the horizontal support assembly 100 has a base 110 and a vertical sleeve 120 axially movably connected with the base 110, and a locking device is provided at the movably connected place. The structure of its movable connection and the locking device at the movable connection can adopt the existing technology in this technical field, such as the movable connection can be the rotating and matching mode of the rotating shaft and the sleeve, the general hinged joint mode or the pivotal joint mode, etc., as long as it can reach vertical The function that the axle sleeve 120 realizes 360° rotation on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com