Light emitting diode module, backlight source and display device

A technology of light-emitting diodes and backlights, which is applied in the fields of light-emitting diode modules, backlights, and display devices. It can solve problems such as inaccurate positioning of LEDs, weakened close contact between LEDs and light guide plates, and waste of light sources. Point phenomenon, good connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

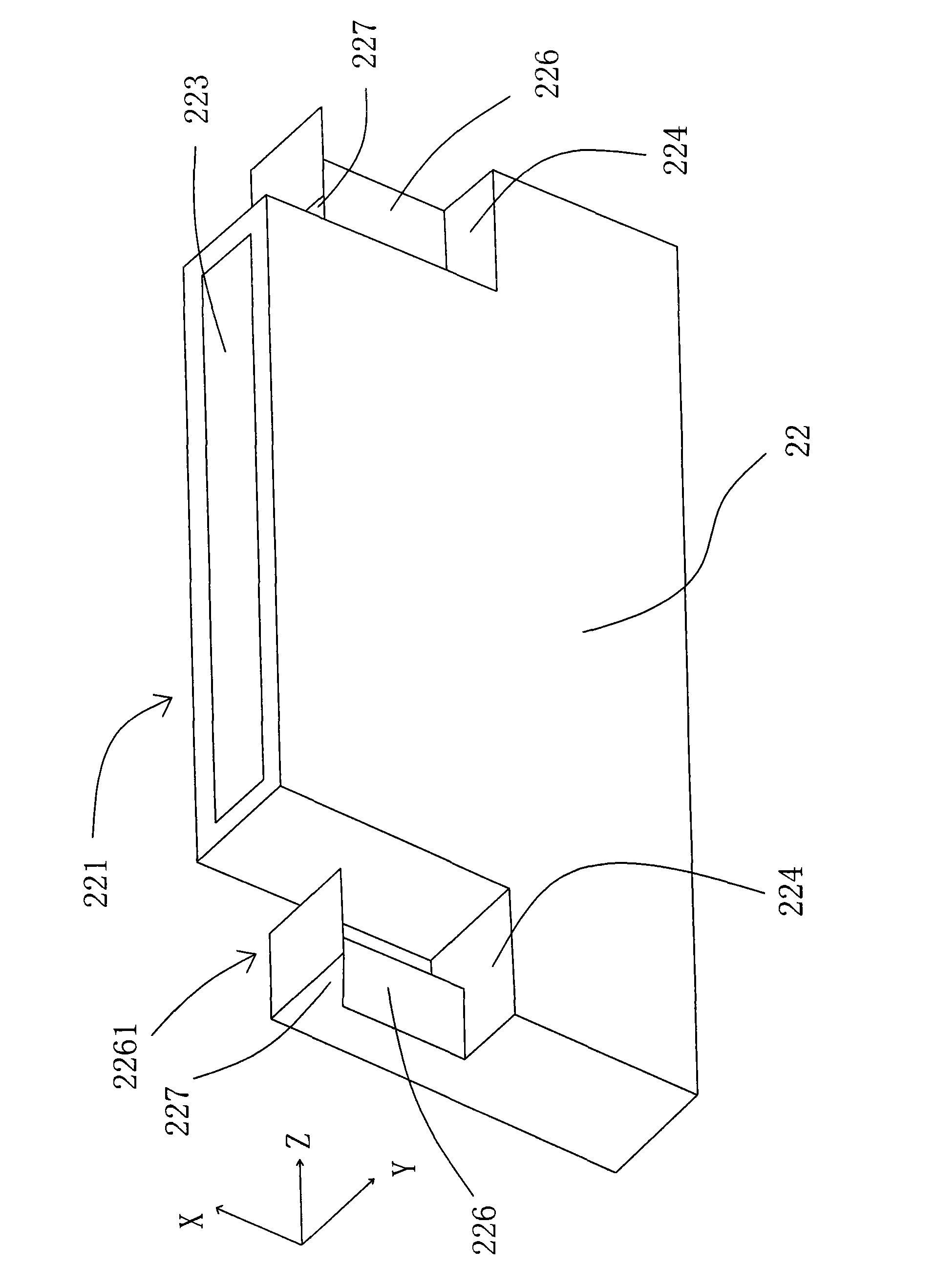

[0021] Please refer to figure 2 , figure 2 A schematic bottom perspective view of the LED module according to the first embodiment of the present invention is shown. The light-emitting diode module 22 of this embodiment includes a light-emitting surface 223 (parallel to the YZ plane in the figure) on its light-emitting side 221; two bumps 226 located on the light-emitting side 221 and on both sides of the light-emitting surface 223; Two positioning blocks 227 respectively located on the two protrusions 226 and pointing to the first side direction of the LED module 22 (ie, the Y-axis direction in the figure), the first side direction is parallel to the light-emitting surface 223 and perpendicular to the direction of the line connecting the two bumps (that is, the direction of the Z axis in the figure).

[0022] In this embodiment, the light-emitting diode module 22 has grooves 224 on both sides of the light-emitting surface 223, the protrusions 226 are placed in the grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com