Multifunctional gaseous phase anti-rust oil

A gas-phase anti-rust, multi-functional technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems that have not been completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Take 91 parts of No. 25 transformer oil, 5 parts of oil-soluble gas-phase corrosion inhibitor, 2 parts of co-solvent, 0.5 part of defoamer, 1 part of antioxidant, 0.5 part of anti-fungal agent, and make the oil-soluble gas-phase corrosion inhibitor When the agent is lower than 120°C, add co-solvent and a small amount of No. 25 transformer oil, heat and melt, and when the oil-soluble vapor phase corrosion inhibitor is completely melted, slowly add it to the reaction kettle, stirring while adding, Then add antifungal agent, defoamer and antioxidant in turn, and keep stirring in a reaction kettle at 90°C for 2 hours to make gas-phase antirust oil.

Embodiment 2

[0014] Example 2: Take 86 parts of No. 25 transformer oil, 10 parts of oil-soluble gas-phase corrosion inhibitor, 2 parts of cosolvent, 0.5 part of defoamer, 1 part of antioxidant, 0.5 part of mold inhibitor, and the preparation method is the same as that of Example 1 .

Embodiment 3

[0015] Example 3: Take 81 parts of No. 25 transformer oil, 15 parts of oil-soluble vapor phase corrosion inhibitor, 2 parts of cosolvent, 0.5 part of defoamer, 1 part of antioxidant, and 0.5 part of antifungal agent. The preparation method is the same as in Example 1 .

[0016] The technical indicators of the vapor phase antirust oil of the above-mentioned embodiments are shown in Table 1.

[0017] Table 1 Technical indicators of vapor phase antirust oil

[0018]

[0019] The antirust performance of the above examples was verified by the following tests.

[0020] 1. Static non-contact acceleration test

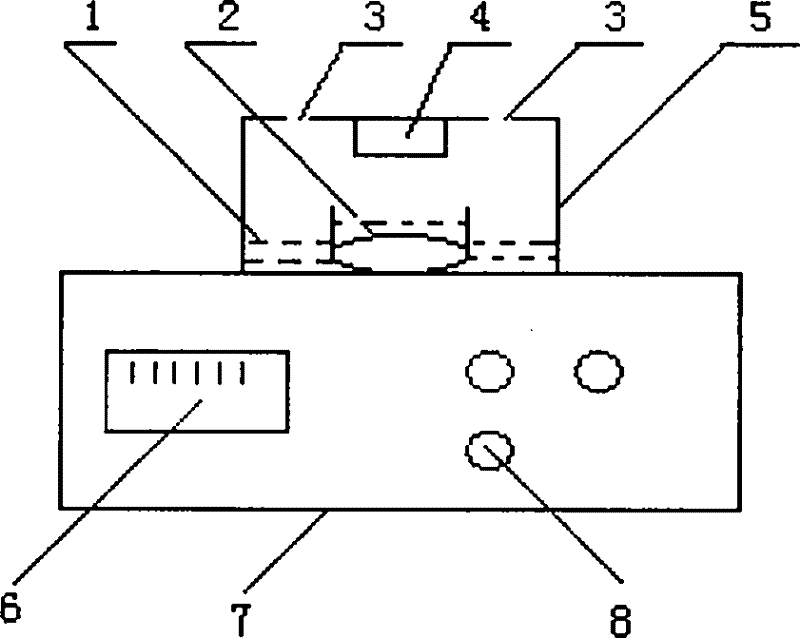

[0021] This test is used to verify the vapor phase antirust effect of Examples 1-3. The experimental device is attached figure 1 , the reference numeral 1 is the electrolyte solution, the numeral 2 is the vapor phase anti-rust oil, the numeral 3 is the vent hole, the numeral 4 is the metal test piece, the numeral 5 is the 800mL beaker, the numeral 6 is the voltage indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com