Method for packaging high-furnace cooling wall

A packaging method and stave technology, which is applied in the field of packaging and transportation of large and medium-sized parts of metallurgical equipment, and can solve problems such as bulkiness, economic loss, and large quantity

Inactive Publication Date: 2011-07-20

周传禄

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The blast furnace cooling stave is a key component of the ironmaking blast furnace. According to its installation in the blast furnace, it is divided into six walls: inner, outer, upper, lower, left, and right. The inner and outer walls are centered on the center line of the blast furnace. The concentric arc surface is the key working surface of the stave. The inner wall faces the furnace core and is arranged in the form of a plane or inlaid bricks. A group or groups of cooling water pipes are installed on the outer wall to force water to cool the stave of the blast furnace when the blast furnace is working. Safe operation of the blast furnace; depending on the location of the blast furnace model, the cooling stave ranges from several hundred kilograms to several thousand kilograms. Reasonably cause stave damage and scrapping, causing serious economic losses, forcing relevant companies to continuously strengthen product packaging, so that the packaging cost reaches 10-15% of the product cost, but due to the lack of reasonable packaging methods, it is still difficult to eliminate the problems caused by packaging problems. loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] Example 2:

Embodiment 2

[0017] Example 3:

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

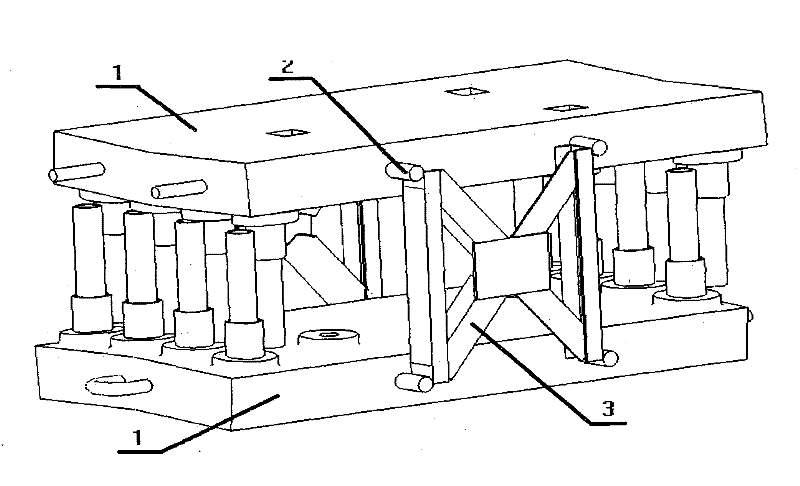

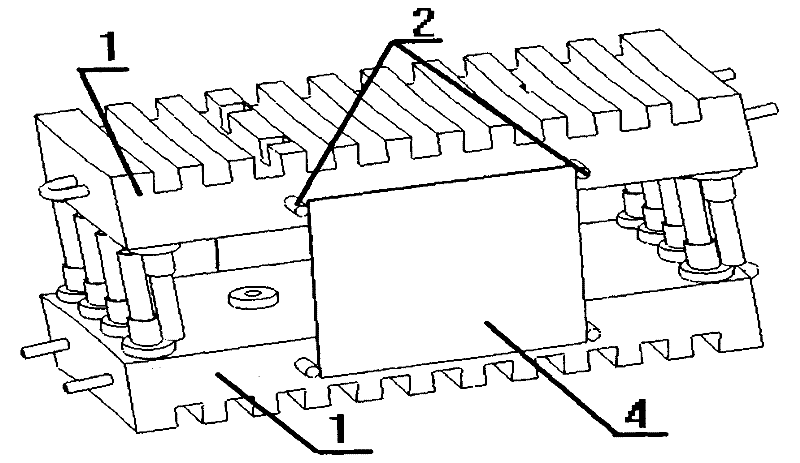

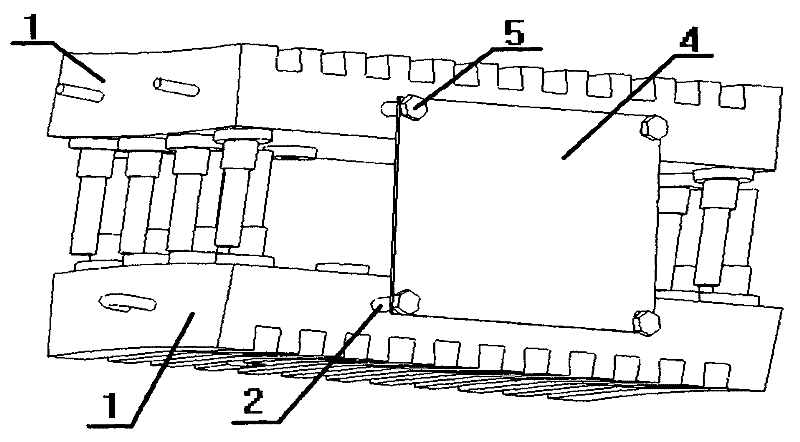

The invention relates to a method for packaging a high-furnace cooling wall, comprising the following steps: overlapping the outer walls of two high-furnace cooling walls back to back so that an inlet and outlet pipe opening is protected by the two cooling walls; installing a prefabricated packaging bracket on a packaging cross arm of each cooling wall so that the two cooling walls form a firm integrity with an inward outer wall convex cambered surface inlet and outlet pipe opening and an outward inner wall concave cambered surface to ensure safety and reliable storage, transportation as wellas assembly and disassembly, wherein the packaging cross arm of each cooling wall is made of round steel or profile steel; the packaging cross arms of the two cooling walls are respectively arranged at the left side and the right side of the cooling wall with a space of 20-90 percent of the length of the cooling wall, and cast together with a high-furnace cooling wall body to ensure that the packaging bracket obtains a firm and effective fulcrum; the packaging bracket of the cooling wall is made of profile steel or the whole block of steel plate and welded with the packaging cross arm of the cooling wall or fastened together with a screw.

Description

technical field [0001] The invention relates to a method for packaging cooling staves of a blast furnace, and belongs to the field of packaging and transportation of large and medium-sized parts of metallurgical equipment. Background technique [0002] The blast furnace cooling stave is a key component of the ironmaking blast furnace. According to its installation in the blast furnace, it is divided into six walls: inner, outer, upper, lower, left, and right. The inner and outer walls are centered on the center line of the blast furnace. The concentric arc surface is the key working surface of the stave. The inner wall faces the furnace core and is arranged in the form of a plane or inlaid bricks. A group or groups of cooling water pipes are installed on the outer wall to force water to cool the stave of the blast furnace when the blast furnace is working. Safe operation of the blast furnace; depending on the location of the blast furnace model, the cooling stave ranges from...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D71/50C21B7/10

Inventor 姚朝胜魏新民衣忠德刘洪亮马平胜周传禄

Owner 周传禄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com