Equipment and method for salvaging granular materials in liquid

A technology for granular materials and liquids, applied in chemical instruments and methods, chemical/physical processes, feeding/discharging devices of settling tanks, etc., can solve problems such as overloading of lifting equipment, accumulation of bulky materials, hardening, etc., to achieve The structure of the equipment is reasonable, the operation is convenient, and the dehydration work is smooth and effective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of salvage equipment for granular materials in liquid, which includes: a liquid pool filled with liquid or an equipment inner cavity, a compressed gas nozzle, a compressed gas source, a discharge port, a fishing pool, a fishing device and a controller, wherein the A fixed liquid level is maintained in the liquid pool or the inner cavity of the equipment, the discharge port is set at the bottom of the liquid pool or the inner cavity of the equipment, and the fishing pool passes through the discharge port and the liquid pool or the inner cavity of the equipment connected, the compressed gas nozzle is installed in the liquid pool or the position where the material is easy to accumulate in the inner cavity of the equipment and the position where the material is easy to accumulate in the fishing pool, and the fishing device is set at the position where the material is easy to accumulate The pool is used to salvage the material in the liquid, and the controller is used ...

Embodiment 2

[0023] Taking the metallurgical slag granulation equipment as an example, the preferred embodiment of the present invention will be further described in detail:

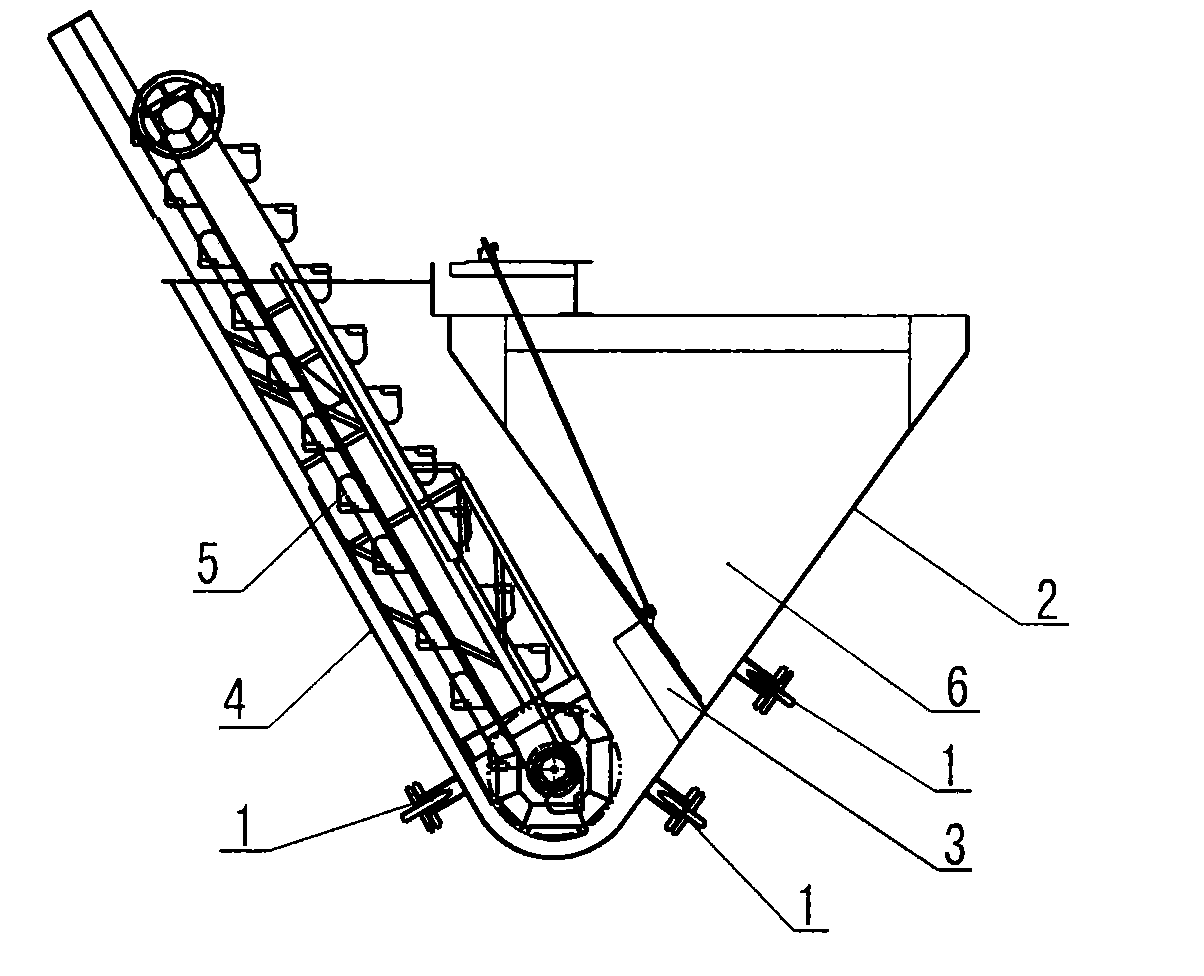

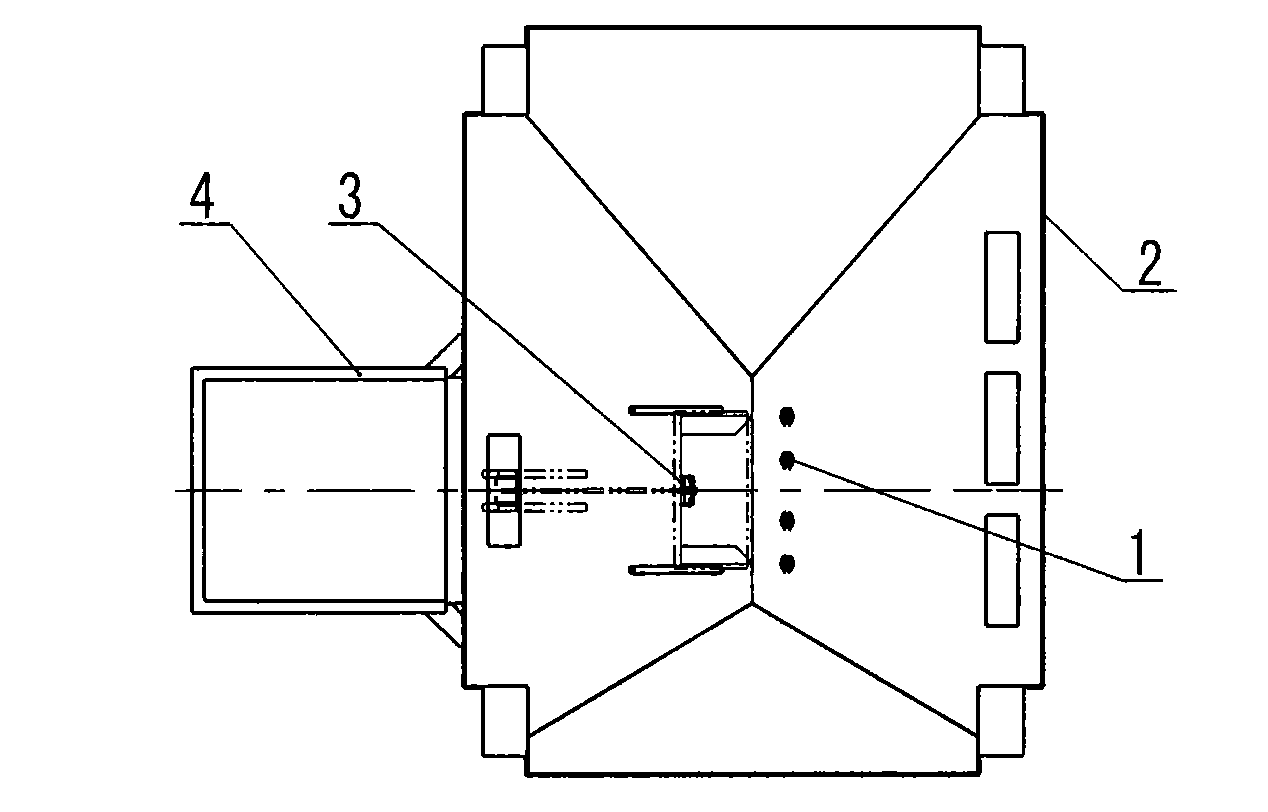

[0024] like figure 1 , 2 As shown, the salvage equipment for granular materials in liquid of the present invention includes: compressed gas nozzle 1, liquid pool 2, discharge port 3, slag removal pool 4, lifting dehydration device 5, liquid medium 6, etc., slag removal pool 4 and The liquid pool 2 is connected through the discharge port 3, the two pools are filled with liquid medium 6, the liquid level is fixed, and the lifting dehydration device 5 is inserted into the slag removal pool 4. After the granular material enters the liquid pool 2, it continues to settle in the liquid medium 6 under the action of gravity, falls to the bottom of the liquid pool 2, and enters the lifting and dehydrating device 5 through the discharge port 3 for lifting and dehydrating operations. When there is too much incoming granular ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com